ข่าว

-

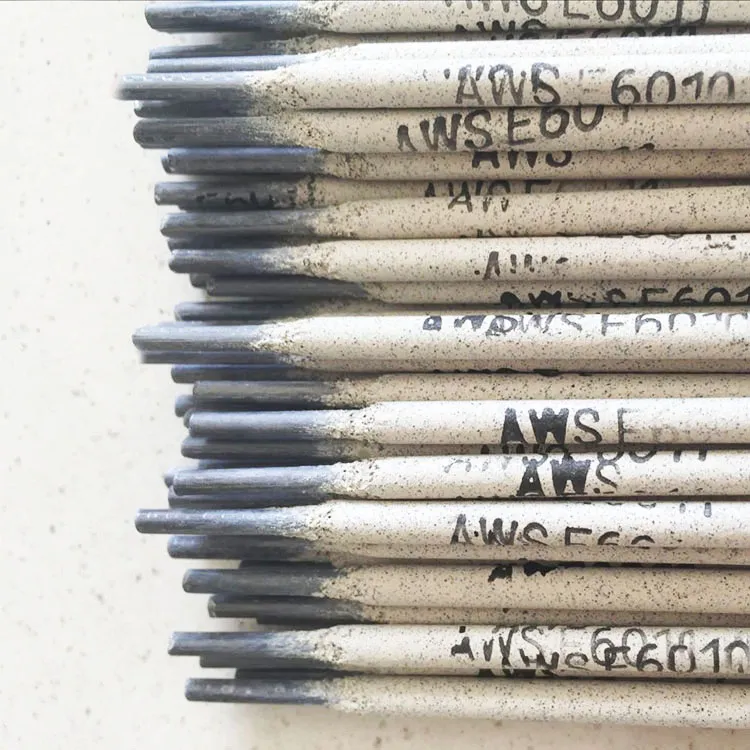

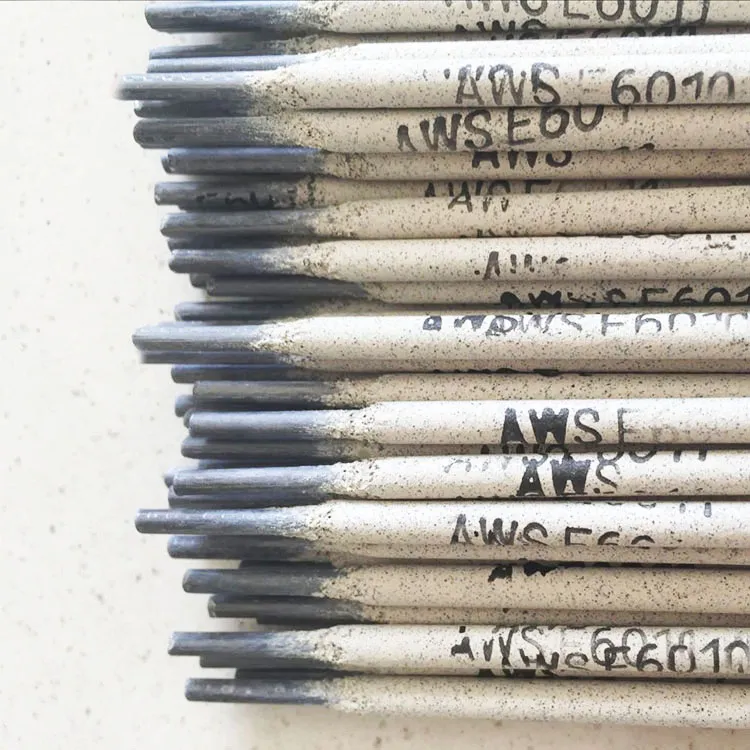

Welding is an essential process in various industries, from construction to automotive manufacturing.อ่านเพิ่มเติม

Welding is an essential process in various industries, from construction to automotive manufacturing.อ่านเพิ่มเติม -

Welcome to your ultimate guide to gasless mig welding wire, a versatile and efficient choice for a wide range of welding applications.อ่านเพิ่มเติม

Welcome to your ultimate guide to gasless mig welding wire, a versatile and efficient choice for a wide range of welding applications.อ่านเพิ่มเติม -

Are you on the hunt for high-quality flux core wire? Look no further! We’ve got an exceptional selection of flux core wire types that cater to every welding need.อ่านเพิ่มเติม

Are you on the hunt for high-quality flux core wire? Look no further! We’ve got an exceptional selection of flux core wire types that cater to every welding need.อ่านเพิ่มเติม -

Welcome to our comprehensive guide on flux core aluminum wire for sale.อ่านเพิ่มเติม

Welcome to our comprehensive guide on flux core aluminum wire for sale.อ่านเพิ่มเติม -

Welcome to our comprehensive guide on flux core wire types, a critical component in the field of welding.อ่านเพิ่มเติม

Welcome to our comprehensive guide on flux core wire types, a critical component in the field of welding.อ่านเพิ่มเติม -

When it comes to welding and fabrication, the choice of welding wire can significantly impact the quality and efficiency of your work.อ่านเพิ่มเติม

When it comes to welding and fabrication, the choice of welding wire can significantly impact the quality and efficiency of your work.อ่านเพิ่มเติม -

If you’re searching for reliable and efficient welding equipment, you’ve come to the right place!อ่านเพิ่มเติม

If you’re searching for reliable and efficient welding equipment, you’ve come to the right place!อ่านเพิ่มเติม -

In the bustling environment of a factory's tool shop, it's imperative that safety protocols during complex tasks such as resistance welding are rigorously followed to prevent mechanical injuriesอ่านเพิ่มเติม

In the bustling environment of a factory's tool shop, it's imperative that safety protocols during complex tasks such as resistance welding are rigorously followed to prevent mechanical injuriesอ่านเพิ่มเติม -

Welding is a critical process used in various industries for joining materials, especially metals, to create robust structures.อ่านเพิ่มเติม

Welding is a critical process used in various industries for joining materials, especially metals, to create robust structures.อ่านเพิ่มเติม -

In the bustling environment of a welding workshop, the throbbing hum of machinery and the intense heat of molten metals serve as everyday reminders of the potential dangers inherent in the trade.อ่านเพิ่มเติม

In the bustling environment of a welding workshop, the throbbing hum of machinery and the intense heat of molten metals serve as everyday reminders of the potential dangers inherent in the trade.อ่านเพิ่มเติม -

Welcome to your ultimate guide to gasless mig welding wire, a versatile and efficient choice for a wide range of welding applications.อ่านเพิ่มเติม

Welcome to your ultimate guide to gasless mig welding wire, a versatile and efficient choice for a wide range of welding applications.อ่านเพิ่มเติม -

Are you on the hunt for high-quality flux core wire? Look no further! We’ve got an exceptional selection of flux core wire types that cater to every welding need.อ่านเพิ่มเติม

Are you on the hunt for high-quality flux core wire? Look no further! We’ve got an exceptional selection of flux core wire types that cater to every welding need.อ่านเพิ่มเติม