4 gauge welding wire manufacturers

The Importance of 4% Gauge Welding Wire Manufacturers in the Industry

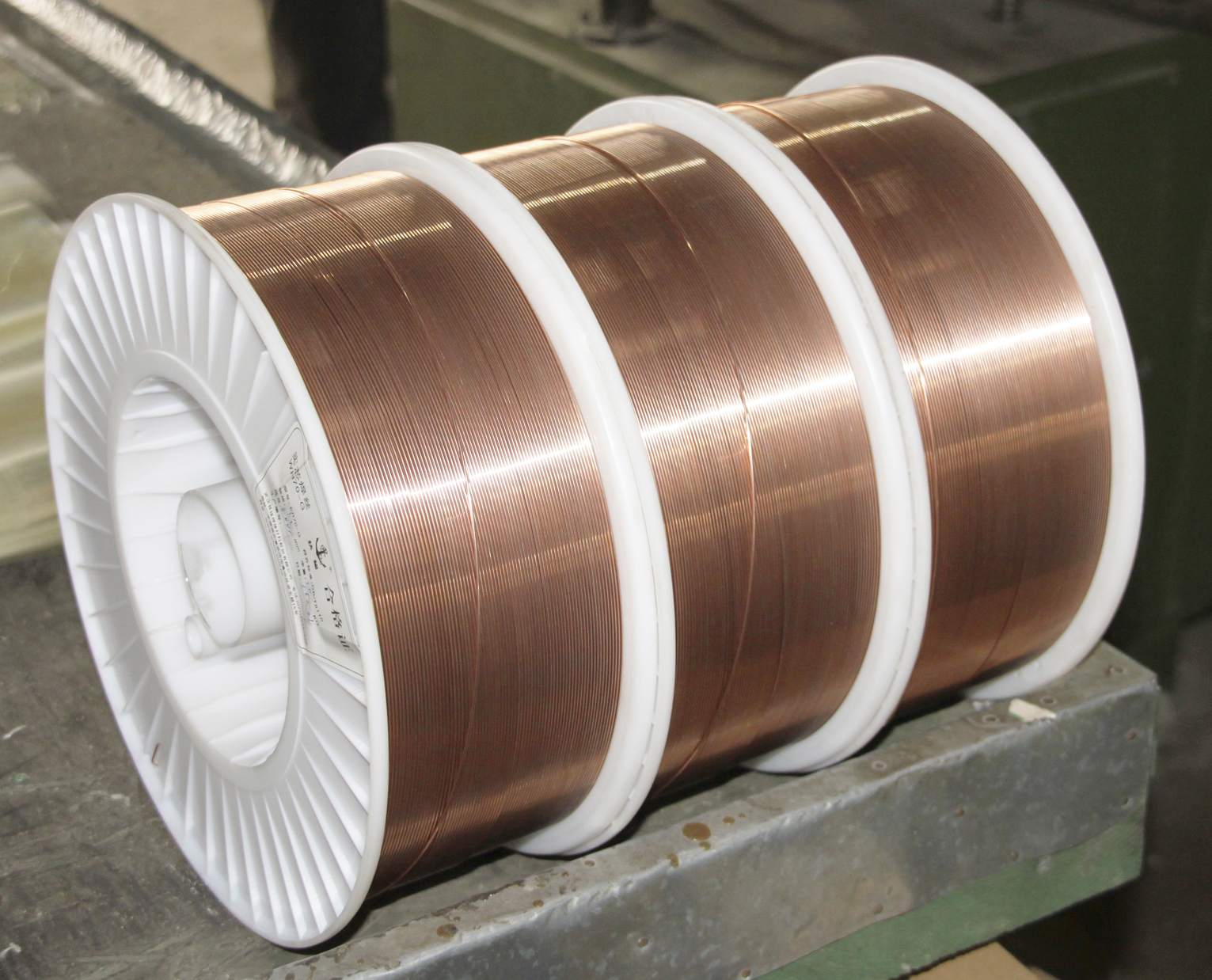

Welding is a critical process in various industries, from automotive to construction, and the quality of welding wire used can significantly impact the integrity and durability of the finished product. Among the various types of welding wires available, 4% gauge welding wire has gained considerable attention due to its unique properties and applications. Manufacturers of this specific thickness play a vital role in ensuring that industries have the materials they need to produce high-quality welds.

Understanding 4% Gauge Welding Wire

The term gauge in welding wire refers to the thickness of the wire. A 4% gauge typically denotes a wire size that balances strength and flexibility, suitable for a variety of welding applications. This size is favored for its ability to deliver consistent performance while providing ease of use for welders. The 4% gauge welding wire is often made from materials such as stainless steel, carbon steel, or other alloys, which are selected based on the specific requirements of the job.

The Role of Manufacturers

Manufacturers specializing in 4% gauge welding wire are key players in the welding industry. They are responsible for producing high-quality wire that meets industry standards and certifications. These manufacturers invest in advanced technology and rigorous quality control processes to ensure that their products are reliable and effective. This emphasis on quality helps prevent issues such as inadequate fusion, porosity, or cracking in welds, which can lead to costly repairs or safety hazards down the line.

Moreover, these manufacturers often work closely with their clients to understand their specific needs. Whether it's producing wire with particular alloy compositions or developing custom packaging solutions, they strive to provide tailored solutions that enhance the welding process and meet customer expectations.

Benefits of Using 4% Gauge Welding Wire

Using 4% gauge welding wire has several advantages. First, it offers excellent versatility. This wire can be used in various welding processes, including MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and submerged arc welding, making it suitable for different applications. Its flexibility allows welders to maneuver easily while maintaining precision, leading to better overall weld quality.

4 gauge welding wire manufacturers

Secondly, the mechanical properties of 4% gauge welding wire contribute to stronger welds. Its balanced composition usually results in enhanced tensile strength and resistance to wear and corrosion. This durability is especially important in sectors such as construction and manufacturing, where the longevity of fabricated components is critical.

Challenges Faced by Manufacturers

While the demand for high-quality welding wire is robust, manufacturers of 4% gauge welding wire face several challenges. One significant challenge is the fluctuating prices of raw materials. Changes in the cost of metals used in welding wire can affect production costs and ultimately influence pricing structures for customers.

Additionally, the manufacturers must stay updated with evolving industry standards and regulations. Compliance with safety and environmental regulations is not just a legal requirement but also a commitment to producing safe and sustainable products. This necessitates continuous investment in research and development, as well as employee training.

The Future of 4% Gauge Welding Wire Production

Looking ahead, the future of 4% gauge welding wire production is promising. With advancements in technology, manufacturers are expected to deliver even better quality products that enhance efficiency and performance in welding applications. Innovations such as automated production processes and enhanced material science will likely lead to the development of welding wires that are not only stronger but also more eco-friendly.

Furthermore, as industries push towards sustainable practices, manufacturers will need to adapt by sourcing materials responsibly and reducing waste in their production processes. By aligning with these industry trends, manufacturers can not only meet market demand but also contribute positively to the environment.

Conclusion

In summary, 4% gauge welding wire manufacturers play a crucial role in the welding industry. Through their dedication to quality, innovation, and customer service, they help ensure that industries have access to reliable welding materials. As technology advances and industries evolve, these manufacturers will continue to be at the forefront, providing essential products that support safe and effective welding practices.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025