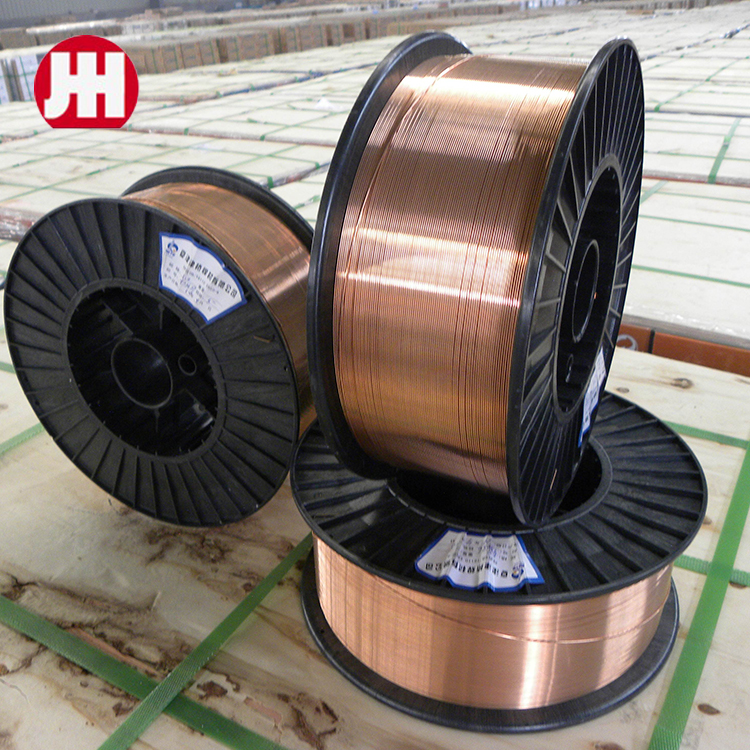

china 0.030 welding wire manufacturer

The Emerging Landscape of Welding Wire Manufacturing in China

In recent years, China has cemented its status as a dominant player in various manufacturing sectors, and the welding wire industry is no exception. With the growing demand for high-quality welding wires driven by advancements in construction, automotive, and manufacturing industries, Chinese manufacturers have risen to the occasion, continuously enhancing their processes and offering a wide range of products to meet both domestic and international needs.

Welding wires are fundamental in various applications, serving as the backbone of welding operations. Whether in the construction of skyscrapers, the automotive assembly line, or shipbuilding, reliable welding wire is critical for the integrity and longevity of the welded structures. As a result, manufacturers have focused on producing a diverse range of welding wires, including solid wires, flux-cored wires, and metal-cored wires, each designed to cater to different welding processes and requirements.

The Emerging Landscape of Welding Wire Manufacturing in China

Moreover, the rise of automation and digital technology within the industry has played a crucial role in enhancing production efficiency and product quality. Many manufacturers are now adopting advanced manufacturing techniques such as robotics and data analytics to streamline their operations. This shift not only reduces production costs but also improves the consistency and reliability of welding wires, which is imperative for customers in critical sectors.

china 0.030 welding wire manufacturer

The sustainability aspect of manufacturing is also becoming increasingly relevant. Chinese manufacturers are now focusing on eco-friendly practices by investing in cleaner production methods and materials. This shift aligns with global trends towards sustainability and environmental responsibility, which is becoming a significant purchasing factor for clients across different sectors.

Furthermore, as global trade dynamics evolve, Chinese welding wire manufacturers are forging strategic partnerships with firms around the world. These collaborations not only facilitate the exchange of technology and innovation but also enable manufacturers to understand and tailor their products to meet the specific needs of international markets. This agility in adapting to market demands has allowed Chinese manufacturers to expand their footprint beyond domestic borders and gain significant market share.

Quality assurance and certification are key elements in establishing trust with international clients. Many Chinese manufacturers are obtaining certifications from governing bodies, ensuring their products meet international standards such as ISO and AWS. This commitment to quality reassures customers that they are receiving reliable and high-performance welding wires suitable for demanding applications.

In conclusion, the welding wire manufacturing industry in China is rapidly evolving, driven by technological advancements, competitive pricing, and a commitment to quality and sustainability. As global demand for high-quality welding solutions continues to rise, Chinese manufacturers are well-positioned to play a crucial role in satisfying this need. With their capacity for innovation and adaptation, they are not just meeting current market demands but also paving the way for the future of welding technology. This positions China as a key player in the global welding wire market, fostering further growth and development in the years to come.

-

Premium AC Stainless Steel Welding Rods - Durable & Corrosion-ResistantNewsAug.05,2025

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025