china 025 flux cored welding wire suppliers

China 20025 Flux Cored Welding Wire Suppliers An Overview

In today's global manufacturing landscape, the demand for high-quality welding materials has surged, leading to an increased interest in flux-cored welding wires. One of the key players in this market is China, which has positioned itself as a leading supplier of flux-cored welding wires, including the popular 20025 variety. This article explores the significance of China’s 20025 flux-cored welding wire suppliers and the advantages they offer to various industries.

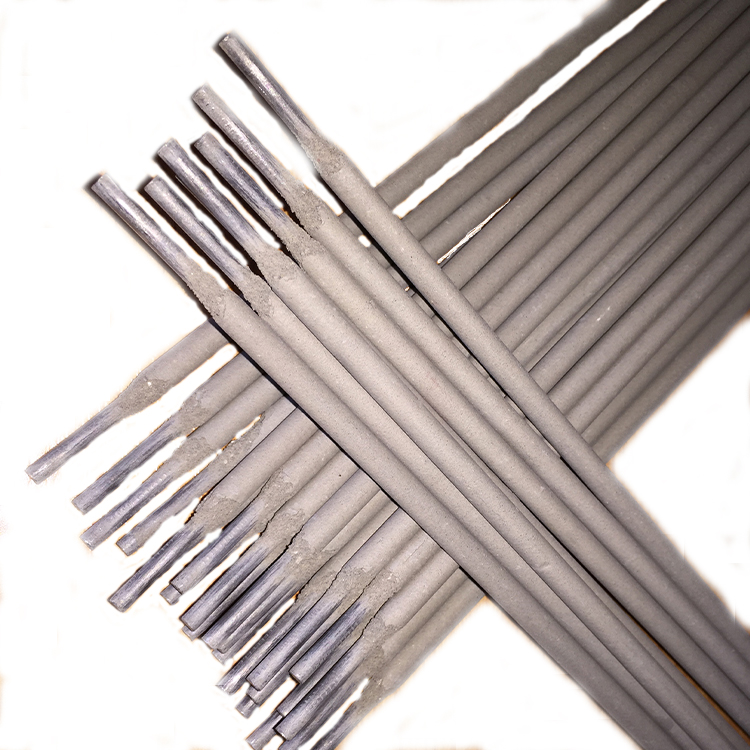

Understanding Flux-Cored Welding Wire

Flux-cored welding wire is a type of filler metal used in the welding process that consists of a metal wire with a core made of flux. This core can either be metallic or non-metallic, providing several benefits during the welding process. The flux acts as a shielding agent, protecting the molten weld pool from atmospheric contamination, ensuring stronger and more reliable joints. The 20025 designation refers to a specific type of flux-cored wire, indicating it is designed for welding carbon steels with excellent mechanical properties.

The Role of China as a Leading Supplier

China has evolved into one of the largest producers and suppliers of welding materials in the world. The country boasts a rich resource base, integrated supply chains, and advanced manufacturing capabilities. The extensive industrial base in China allows for the production of high-quality welding wires at competitive prices, attracting businesses from around the globe. The country’s investment in research and development further enhances the quality of its welding products, including the 20025 flux-cored welding wire.

One of the vital attributes of Chinese suppliers is their ability to meet varying customer demands. Chinese manufacturers are known for their flexibility in production, allowing them to cater to large-scale orders while also providing customized solutions to meet specific project requirements. This adaptability is crucial in industries where timelines and quality standards are stringent.

Advantages of Using 20025 Flux-Cored Welding Wire

1. High Efficiency The 20025 flux-cored welding wire offers a higher deposition rate compared to traditional welding methods. This efficiency translates to shorter welding times without compromising the quality of the weld, making it an ideal choice for high-production environments.

2. Versatile Applications This type of welding wire is particularly suitable for various applications, including construction, automotive manufacturing, and shipbuilding. Its ability to perform well in both indoor and outdoor settings makes it a favorite among many welders.

china 025 flux cored welding wire suppliers

3. Improved Weld Quality As flux-cored welding wires provide excellent arc stability and control, welders can expect minimal spatter and better penetration. This leads to stronger and cleaner welds, reducing the need for extensive post-welding processing.

4. Cost-Effectiveness Given China's vast production capabilities, the cost of acquiring 20025 flux-cored welding wire is generally lower compared to suppliers from other regions. This cost-effectiveness, combined with the high quality of the product, ensures better return on investment for companies.

Key Considerations when Choosing Suppliers

While there are numerous suppliers of 20025 flux-cored welding wire in China, it is vital for businesses to evaluate potential partners carefully. Here are some key considerations

1. Quality Assurance Look for suppliers that adhere to international quality standards, such as ISO certifications. This ensures that the products meet specific performance criteria.

2. Reputation and Reviews Research the supplier's reputation in the market. Feedback from previous customers can provide insights into the reliability and quality of their products.

3. Support and Services Consider suppliers that offer after-sales support and technical assistance. Good customer service can be invaluable, especially for businesses new to using flux-cored welding wire.

4. Shipping and Logistics Evaluate the supplier’s logistics capabilities. Efficient shipping processes are crucial in minimizing delays and ensuring timely delivery of materials.

Conclusion

The demand for quality welding materials continues to rise globally, and China stands out as a significant supplier of flux-cored welding wire, particularly the 20025 variety. With its ability to produce high-quality, cost-effective products, Chinese suppliers are well-equipped to meet the needs of various industries. By carefully selecting the right suppliers, businesses can leverage the advantages of using Chinese flux-cored welding wires to enhance their operations and maintain competitive edges in their respective markets.

-

J506 Welding Rod: High-Strength, Crack-Resistant ElectrodeNewsAug.23,2025

-

E71T-1 Shielding Gas for Superior Welding Quality & EfficiencyNewsAug.22,2025

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025