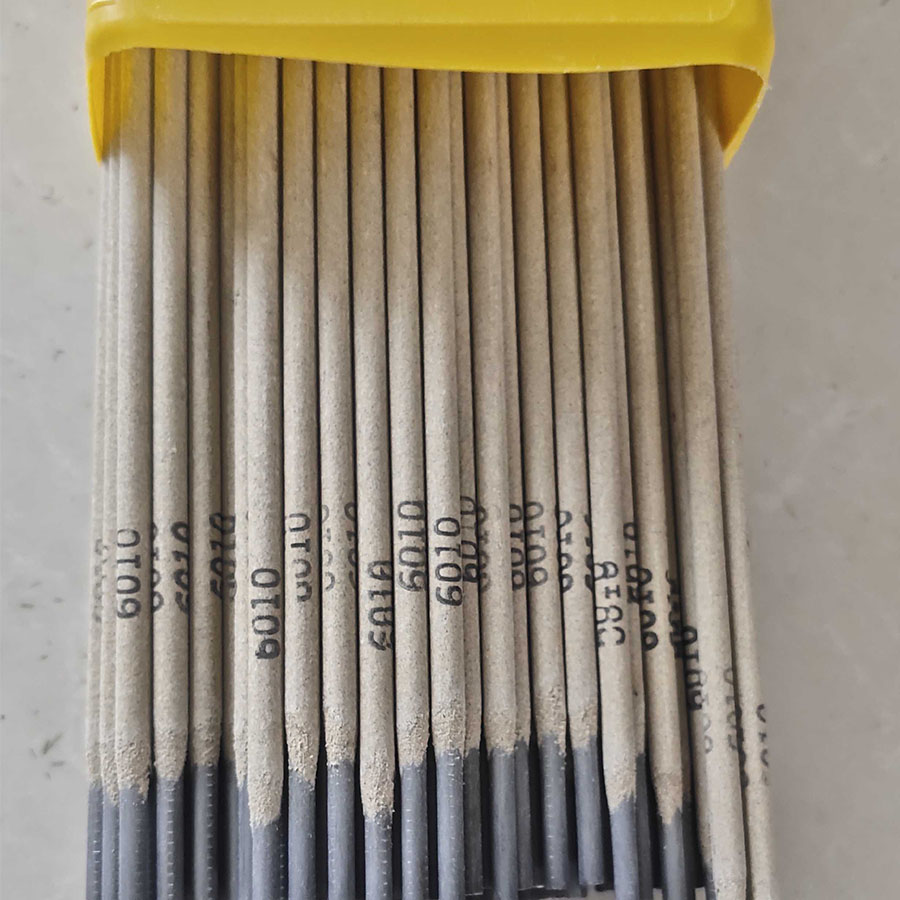

china electrode welding 2.6mm

The Significance of 2.6mm Electrode Welding in China

In recent years, China's welding industry has witnessed significant transformation, driven by advancements in technology and increasing demand for high-quality welding solutions. Among various dimensions of welding practices, the 2.6mm electrode welding has gained prominence due to its versatility and efficiency across multiple applications. This article delves into the importance of 2.6mm electrode welding in China, highlighting its applications, benefits, and the future of welding techniques in the country.

Understanding Electrode Welding

Welding is a critical process in metal fabrication and construction, involving the joining of materials through heat and pressure. Electrode welding, often referred to as arc welding, utilizes a consumable electrode to create an electric arc, melting both the electrode and the base metal. This allows for a strong, cohesive bond once the materials cool down. Electrode diameter is crucial in determining the welding technique’s effectiveness, and 2.6mm electrodes have become a preferred choice among welders for various reasons.

Applications of 2

.6mm ElectrodesThe 2.6mm electrode welding is particularly favored in several industries that require precise and robust joints. In the automotive sector, for example, welders use 2.6mm electrodes for critical components such as chassis, frame assemblies, and engine parts, where the strength and durability of the weld are paramount.

Another significant application is in the construction industry, where structural steel and rebar are frequently joined. The 2.6mm electrodes offer a perfect balance between the heat needed for fusion and the ability to manage the thermodynamics of thicker materials. Additionally, the manufacturing of household appliances, machinery, and pipelines also benefits from this welding size, ensuring robustness without excessive material consumption.

Advantages of Using 2.6mm Electrodes

china electrode welding 2.6mm

One of the primary advantages of using 2.6mm electrodes is their adaptability. They work well with various materials, including mild steel, stainless steel, and other alloys. This versatility makes them suitable for both thin and moderately thick materials, facilitating a wide range of welding applications.

In terms of efficiency, 2.6mm electrodes provide a good compromise between speed and quality. The electric arc generated is controlled, allowing for clean and accurate welds, which is crucial in applications requiring precision. Furthermore, this size minimizes the occurrence of defects such as undercutting, porosity, and cracks, which can compromise the integrity of the weld.

From an economic standpoint, 2.6mm electrodes are cost-effective. They minimize the amount of electrode waste since the size allows for more extended use without frequent replacements. This is particularly beneficial for businesses in China’s highly competitive manufacturing sector, where operational costs must be kept in check.

The Future of Electrode Welding in China

As China continues to strengthen its position as a global manufacturing powerhouse, the welding industry is anticipated to evolve further. The advent of smart manufacturing and automation is likely to impact welding techniques, including the potential integration of robotic systems that can use 2.6mm electrodes for improved efficiency and precision.

Moreover, the focus on sustainable practices will drive innovation in welding technologies. As industries look for greener alternatives, there may be a push towards developing eco-friendly welding materials and processes. 2.6mm electrodes can play a role in this transition by providing a less intensive resource requirement, thereby aligning with environmental objectives.

In conclusion, the significance of 2.6mm electrode welding in China cannot be overstated. Its multifaceted applications across various sectors, coupled with the advantages it offers in terms of efficiency and cost-effectiveness, make it an essential component of the country’s welding landscape. As technology progresses and industries evolve, the ongoing adaptation and innovation in electrode welding techniques will continue to support China's growth as a leader in manufacturing and engineering excellence. The future promises exciting developments that will undoubtedly shape the welding industry for years to come.

-

E71T-11 Flux Core Wire: Premium Gasless Welding SolutionNewsAug.28,2025

-

Premium Carbon Rods for Welding | Stable Arc & Precise GougingNewsAug.27,2025

-

Carbon Steel Welding Wire: Superior Strength & PrecisionNewsAug.26,2025

-

AWS E6013 Welding Electrodes: All-Position & Smooth Arc RodsNewsAug.25,2025

-

E312 Electrode: High Strength Welding Rod for Dissimilar MetalsNewsAug.24,2025

-

J506 Welding Rod: High-Strength, Crack-Resistant ElectrodeNewsAug.23,2025