Sourcing High-Quality MIG Welding Wire for Soldering from China Manufacturers

The Emergence of China’s MIG Wire for Soldering An Overview

In recent years, China has positioned itself as a leading manufacturer of MIG (Metal Inert Gas) wire used for soldering, which is an essential component in various industries, including automotive, construction, and electronics. MIG welding, known for its efficiency and versatility, relies heavily on high-quality welding wires to ensure strong, durable connections. As global demand for these products continues to rise, Chinese manufacturers are stepping up to meet the needs of an increasingly competitive market.

Understanding MIG Wire

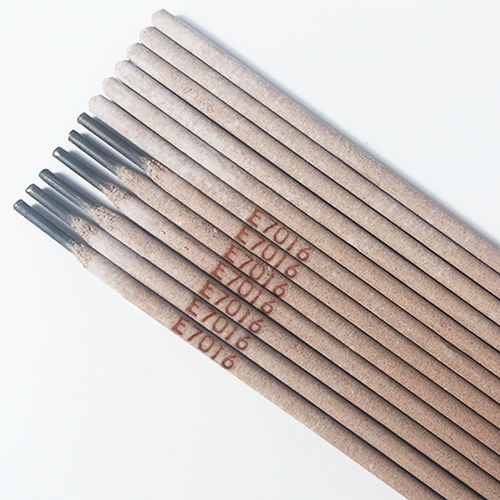

MIG wire is a type of welding wire used in the MIG welding process, where a continuous wire feed provides a filler material to the weld joint. This makes it suitable for various applications, especially in industries that require a robust and efficient welding solution. The wire is typically made from different materials, including mild steel, stainless steel, and aluminum, and is often coated with a layer of flux to protect the weld pool from oxidation and contamination.

China’s innovations in MIG wire production have led to the development of specialized varieties tailored for different materials and welding processes

. This adaptability has made Chinese MIG wires highly sought after in international markets.Advantages of Chinese MIG Wire

1. Cost-Effectiveness One of the primary advantages of sourcing MIG wire from China is cost. Chinese manufacturers benefit from lower production costs, which allows them to offer competitive pricing. This affordability makes it accessible for small and large businesses alike, fostering greater adoption of MIG technology across various sectors.

china mig wire for soldering manufacturer

2. Quality Assurance Contrary to the stereotype that cheaper products come at the expense of quality, many Chinese manufacturers have invested heavily in modern production techniques and quality control processes. They comply with international standards, ensuring that their products deliver consistent performance and durability.

3. Diverse Product Range Chinese manufacturers produce a wide range of MIG wire types, catering to different welding needs. From stainless steel wires to those suitable for specific alloys, customers can find suitable options for their projects. This diversity not only meets the demands of various industries but also encourages innovation in welding technology.

4. Rapid Production Capabilities The advanced manufacturing infrastructure in China enables swift production and delivery. This capability is crucial for industries that work on tight schedules, as they can depend on timely shipments without compromising on quality.

The Global Market Impact

As China continues to dominate the MIG wire manufacturing landscape, the ripple effects on the global market are noticeable. Many countries are now sourcing MIG wires from Chinese manufacturers, which has led to a significant shift in trade dynamics. This trend promotes global competitiveness, driving other nations to enhance their production methods and technologies to keep up.

Conclusion

The rise of Chinese MIG wire manufacturers for soldering represents a blend of affordability, quality, and innovation. As industries around the world increasingly rely on these products, it is clear that China has carved out a significant niche in the global manufacturing landscape. The ongoing advancements in technology and production capabilities promise a bright future for Chinese MIG wire in the global market, making it a key player in shaping the future of welding and soldering techniques. With continued investment in quality and innovation, Chinese manufacturers will remain at the forefront of the MIG wire industry for years to come.

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025