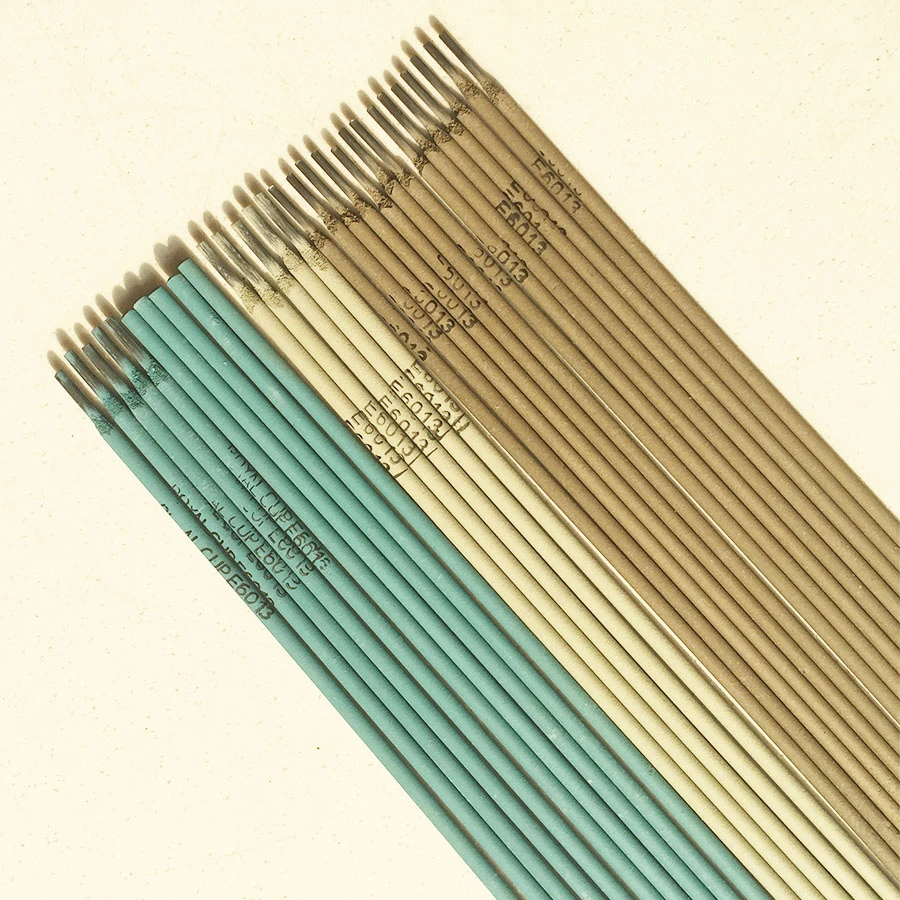

china welding electrode 6013

Understanding China’s Welding Electrode E6013 Key Features and Applications

Welding is an essential process in various industries, and the welding electrodes used can significantly influence the quality and strength of the welds produced. One of the most widely used electrodes in arc welding applications is the E6013. This electrode is particularly known for its versatility, ease of use, and excellent welding characteristics, making it a popular choice in many sectors around the world, including China.

What is E6013?

The E6013 is a type of mild steel welding electrode classified under the American Welding Society (AWS) specification. The 'E' indicates that it is an electrode, '60' refers to the minimum tensile strength of 60,000 psi, '1' signifies the welding position (which means the electrode can be used in all positions), and '3' represents the type of coating, which is primarily composed of cellulose and titanium. This unique formulation allows for stable arcs and smooth weld bead appearance, reducing spatter during the welding process.

Key Features of E6013 Electrodes

1. Versatility One of the standout features of E6013 electrodes is their adaptability to various welding positions, including flat, horizontal, vertical, and overhead. This versatility makes them suitable for both amateur and professional welders.

2. Ease of Use E6013 electrodes are user-friendly, making them ideal for beginners and experienced welders alike. They produce a stable arc with minimal effort, allowing for better control during the welding process.

3. Excellent Weld Appearance The design and coating of E6013 electrodes facilitate a clean and aesthetically pleasing weld bead. This quality is vital in projects where visual appearance is considered, such as in architecture and decorative works.

4. Low Spatter and Fumes Compared to other electrodes, E6013 produces less spatter and smoke, which is a significant advantage in maintaining a clean working environment and reducing the need for extensive post-welding cleanup.

5. Good Penetration and Fusion E6013 electrodes offer good penetration and fusion, allowing welders to achieve strong and durable welds even in challenging positions.

china welding electrode 6013

Applications of E6013 Electrodes in China

In China, E6013 electrodes find applications across a wide range of industries due to their effectiveness and reliability. Some common uses include

- Manufacturing Many manufacturers use E6013 electrodes for fabricating steel structures, frames, and machinery where strong welds are necessary.

- Construction In the construction industry, these electrodes are often used for welding steel reinforcements and joining sections of structural steel in buildings, bridges, and other infrastructures.

- Automotive The automotive sector utilizes E6013 electrodes for welding body parts, frames, and component assembly due to their outstanding weld quality.

- Shipbuilding E6013 electrodes are also employed in shipbuilding, where they contribute to the construction of hulls, decks, and other parts requiring rigorous structural integrity.

- Home Repairs and DIY Projects Due to their ease of use and availability, many DIY enthusiasts and home repair individuals turn to E6013 electrodes for various welding tasks around the house.

Conclusion

The E6013 welding electrode is a versatile and effective tool for welders in China and around the globe. Its combination of strength, usability, and superior weld appearance makes it ideal for a myriad of applications. As the demand for high-quality welding solutions continues to grow, especially in rapidly industrializing nations like China, the E6013 electrode remains a crucial element in the welding toolkit. Whether in industries or DIY projects, it is essential for ensuring lasting and reliable welds that contribute to the overall integrity of constructions and products alike. Understanding the capabilities and applications of E6013 can help welders select the right electrode for their specific needs, ultimately leading to more successful welding experiences.

-

E312 Electrode: High Strength Welding Rod for Dissimilar MetalsNewsAug.24,2025

-

J506 Welding Rod: High-Strength, Crack-Resistant ElectrodeNewsAug.23,2025

-

E71T-1 Shielding Gas for Superior Welding Quality & EfficiencyNewsAug.22,2025

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025