Essential Insights into Welding Rods and Pricing

Welding rods are vital components in the welding industry, offering critical support in joining metals together effectively. Whether you're engaged in construction, manufacturing, or repair, understanding the different types of welding rods, their prices, and their specific uses can make a significant difference in the quality and efficiency of your welding projects. In this article, we will explore the importance of welding rod welding rod, the impact of welding rod price per kg, the specialized use of welding rod for structural steel, the significance of steel welding electrodes, and the advantages of using low hydrogen electrode 7018.

The Importance of Welding Rod Welding Rod

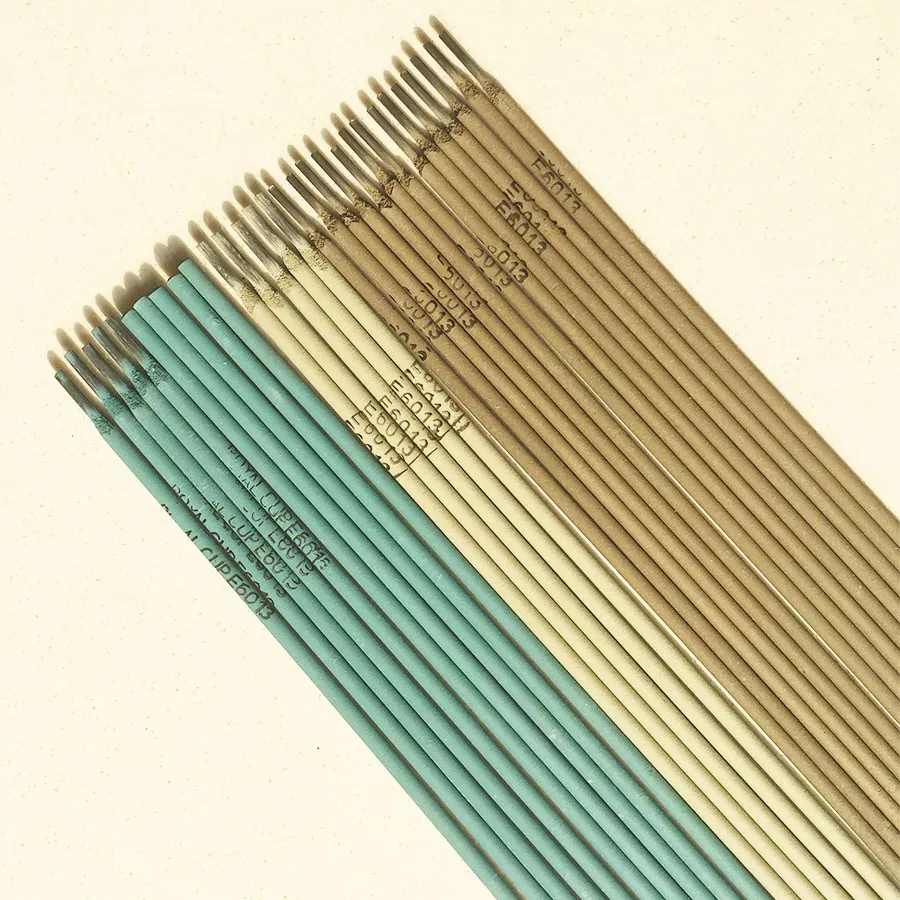

When it comes to welding, welding rod welding rod is a fundamental aspect of the entire process. Welding rods, often referred to as electrodes, are used to create a pool of molten metal during the welding process. These rods serve as both a filler and a source of heat, helping to fuse materials together. The quality of the welding rod you use can significantly impact the quality of the final weld.

In most cases, welding rods are made from materials such as steel, stainless steel, or special alloys designed for specific applications. A high-quality welding rod welding rod ensures better control over the weld, reduced spatter, and a cleaner finish. Additionally, it can help to minimize the risks of defects, such as cracks or porosity, that could weaken the joint. The choice of welding rod welding rod should align with the type of welding process you're using, whether it's stick welding, MIG, or TIG welding, as well as the materials you're working with.

Understanding Welding Rod Price Per Kg

One of the first considerations when purchasing welding rods is the welding rod price per kg. Pricing can vary depending on several factors, including the material composition of the rod, its intended use, and the manufacturer. Typically, higher-quality rods made with premium materials will have a higher price per kilogram. However, the investment in quality welding rods is often worth it for the durability and reliability they provide during the welding process.

The welding rod price per kg is also influenced by market conditions, as well as any additional features, such as special coatings or alloys designed for specific applications. While it may be tempting to opt for cheaper rods to reduce costs, it's important to remember that the quality of the welding rod plays a critical role in the overall success of your welding project. A lower-priced rod may not perform as well, leading to poor weld quality, potential rework, or even safety risks. Therefore, balancing the welding rod price per kg with the required performance is essential for getting the best value.

Choosing Welding Rod for Structural Steel

For those working in construction, infrastructure, or other heavy-duty applications, selecting the right welding rod for structural steel is essential. Structural steel is often used in large construction projects, such as bridges, buildings, and industrial structures, where welds need to be strong, durable, and able to withstand significant stress. The welding rod for structural steel should be chosen based on the type of steel being welded and the conditions the finished weld will be exposed to.

Commonly used welding rods for structural steel include mild steel rods and high-strength rods that offer increased tensile strength and improved resistance to corrosion and fatigue. The right welding rod for structural steel will ensure that the weld is strong enough to hold up under heavy loads, extreme temperatures, and environmental conditions. Choosing a rod that meets the specific requirements of structural steel ensures the safety and longevity of the finished structure.

Steel Welding Electrode: A Critical Component

A steel welding electrode is essential in many welding operations. It provides the necessary filler material to create a strong bond between two pieces of steel. The quality of the steel welding electrode determines how well the steel pieces will be fused and how durable the final weld will be. Steel welding electrodes are available in various types, each designed for a specific application, whether you're welding thin sheets of steel or heavy-duty structural steel.

The composition of the steel welding electrode is key to ensuring that it performs effectively for your project. It must be compatible with the type of steel you are working with, whether it's carbon steel, stainless steel, or alloy steel. Moreover, the correct steel welding electrode will provide the necessary properties to withstand the stresses and pressures placed on the weld, ensuring it remains strong over time and under challenging conditions.

Why Choose Low Hydrogen Electrode 7018?

The low hydrogen electrode 7018 is a popular choice among professional welders due to its outstanding performance and versatility. Known for producing high-quality, crack-resistant welds, this electrode is ideal for use in critical applications, such as pressure vessels, boilers, and structural steelwork. The low hydrogen electrode 7018 is specifically designed to minimize the risk of hydrogen-induced cracking, which can occur in high-strength steel welding.

The low hydrogen electrode 7018 is also favored for its smooth, stable arc and minimal spatter, making it easier to control the welding process and achieve a clean, aesthetically pleasing result. This electrode is suitable for a wide range of welding positions, including vertical and overhead, making it highly versatile. It is commonly used in industries such as manufacturing, construction, and offshore projects, where welds need to withstand high stress and pressure over time.

In conclusion, selecting the right welding rods and electrodes is critical to the success of any welding project. Whether you are focused on cost-effectiveness, the specific requirements of welding rod welding rod, the price per kilogram of welding rods, or the specialized needs of welding rods for structural steel, each component plays a crucial role in ensuring the quality and durability of your welds.

By considering factors like material compatibility, performance, and price, you can make informed decisions that will enhance the effectiveness and longevity of your welds. Furthermore, by investing in reliable steel welding electrodes and high-quality products like the low hydrogen electrode 7018, you ensure that your work meets the highest standards of safety and performance. Ultimately, understanding the nuances of welding rods, their prices, and their applications will help you achieve superior results, whether you're a novice welder or an experienced professional.

-

What is a medium-frequency pulse? What types of welding are suitable for?ข่าวNov.24,2025

-

Why is the overall cost of CO2 welding lower than that of shielded metal arc welding?ข่าวNov.21,2025

-

Welding Knowledge 6ข่าวNov.20,2025

-

What is a low-frequency pulse? What types of welding are they suitable for?ข่าวNov.19,2025

-

Why are the weld joints from CO₂ gas shielded welding of such high quality?ข่าวNov.18,2025

-

J506 Welding Rod - Low Hydrogen, All-Position, AC/DC E7016ข่าวNov.17,2025