Top Manufacturers of Flux Core Stainless Steel MIG Welding Wire in the Industry

Flux Core Stainless MIG Wire Manufacturers A Comprehensive Overview

Flux-cored stainless steel MIG (Metal Inert Gas) wire has emerged as a popular choice among welders and fabrication professionals. This welding wire offers several advantages, including deep penetration, reduced spatter, and the ability to be used in various environments, such as outdoors and in windy conditions. Its unique composition makes it suitable for welding stainless steel, which is widely used in industries requiring high corrosion resistance, such as food processing, marine applications, and chemical production.

Understanding Flux-Cored Wire

Flux-cored wires are a type of welding wire that contains a core of flux material designed to produce shielding gas during the welding process. This is particularly advantageous over solid wires, as it allows for improved performance in outdoor settings and on rusted or dirty materials. The flux in the wire helps to protect the weld pool from atmospheric contamination, leading to stronger and more durable weld joints.

The Advantages of Using Flux-Cored Stainless MIG Wire

1. Deep Penetration One of the major benefits of using flux-cored stainless MIG wire is its ability to penetrate thicker materials. The welding arc generated is hotter, allowing for deeper welds and reduced heat input, which minimizes distortion in the base metals.

2. Versatility Flux-cored stainless steel wires can be used for a variety of applications across different industries. They are not limited to workshop environments; they can be used effectively in field repairs, which is essential for many contractors and service technicians.

3. Reduced Spatter Compared to other welding processes, flux-cored welding produces less spatter, which translates to cleaner welds and reduced post-weld cleanup. This feature is particularly beneficial in high-production environments where speed and efficiency are paramount.

4. Improved Corrosion Resistance Given that the primary application of stainless steel is for its corrosion resistance, using flux-cored stainless MIG wire ensures that completed welds maintain the mechanical properties and corrosion resistance characteristics of the base material.

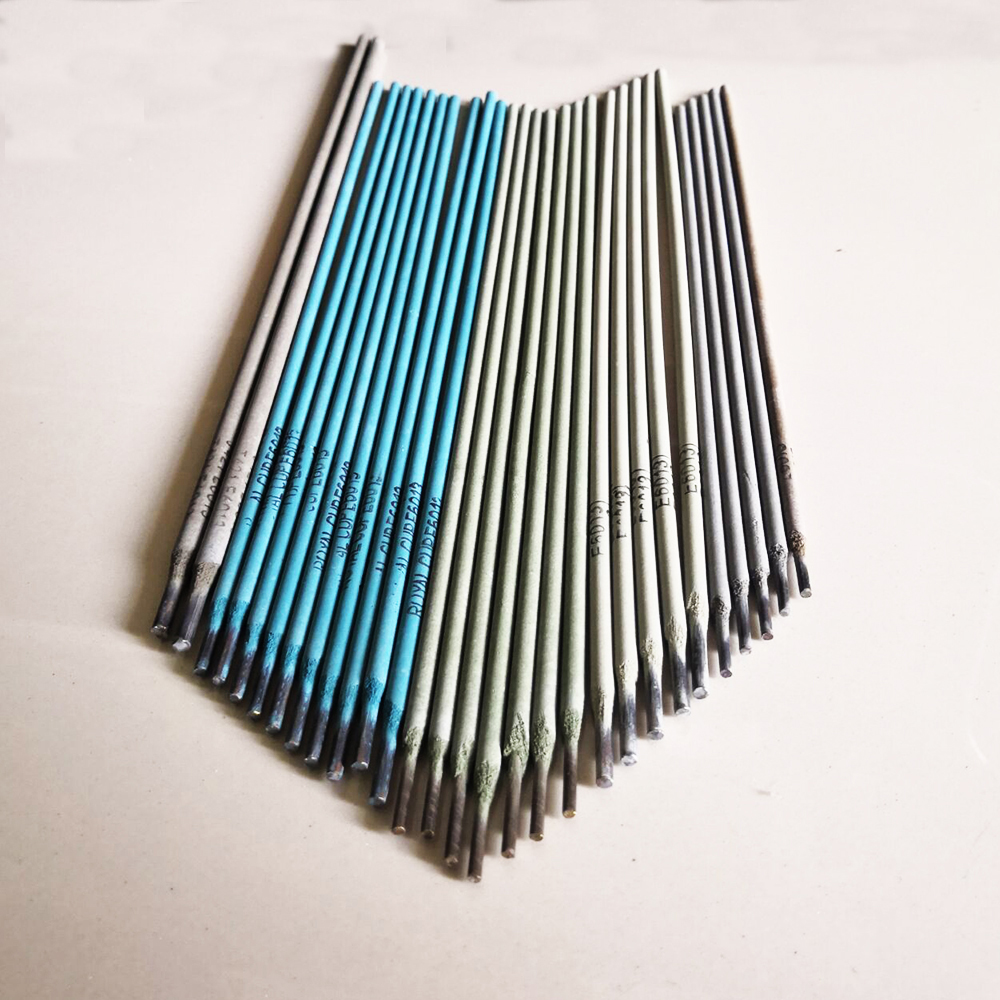

flux core stainless mig wire manufacturers

Leading Manufacturers in the Market

As with any welding materials, the choice of flux-cored stainless MIG wire largely depends on the manufacturer. Several reputable companies have established themselves as leaders in the manufacturing of high-quality flux-cored stainless steel wires.

1. Lincoln Electric One of the pioneers in welding technology, Lincoln Electric offers a range of flux-cored stainless MIG wires known for their reliability and performance. Their products cater to various applications and are praised for their ease of use and consistent quality.

2. Hobart Brothers Hobart Brothers is another key player in the welding industry, providing flux-cored wires that deliver exceptional performance for stainless steel welding. Their wires are designed for high efficiency while maintaining the integrity of the weld.

3. ESAB A global leader in welding and cutting technologies, ESAB offers a diverse range of welding consumables, including flux-cored stainless MIG wires. Their products are known for technological advancement and innovation, ensuring high-quality welds in demanding conditions.

4. Miller Electric Miller Electric focuses on providing versatile and durable welding solutions. Their flux-cored weld wires allow for optimal performance across different applications, facilitating ease of use for professionals and novice welders alike.

5. Kiswel With a solid reputation in manufacturing welding materials, Kiswel specializes in producing flux-cored wires suitable for various industries. Their stainless steel options are engineered to provide high-strength welds and excellent corrosion resistance.

Conclusion

In conclusion, flux-cored stainless MIG wire is an essential material for professionals engaged in welding applications that require strength, durability, and resistance to corrosion. The benefits of using this type of wire, combined with the technology and commitment to quality offered by leading manufacturers, make it an excellent choice for welding stainless steel. When selecting flux-cored wire, it is crucial to consider the specific applications and material types to ensure the best performance. Whether in a workshop or the field, opting for high-quality products from reputable manufacturers can significantly impact the success of any welding endeavor.

-

Premium AC Stainless Steel Welding Rods - Durable & Corrosion-ResistantNewsAug.05,2025

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025