soldadura de electrodo supplier

Understanding Electrode Welding and Its Suppliers

Electrode welding, commonly known as Stick welding, is a process that employs a consumable electrode coated in flux to join metals. The electrode produces an electric arc that melts both the electrode and the base metal, resulting in a weld. This method is popular due to its simplicity, versatility, and effectiveness in various welding applications. As industries evolve, the demand for quality electrode welding products increases, leading to the significant role of suppliers in this sector.

The Basics of Electrode Welding

Electrode welding works by establishing a circuit between the electrode and the workpiece. When the electrode is struck against the base metal, an electric arc forms, producing intense heat that melts the electrode tip and the surrounding metal. The flux coating on the electrode burns off, creating a gas that protects the weld pool from contamination by the environment, thereby ensuring the purity and integrity of the weld.

This welding process is particularly advantageous for outdoor use as it can withstand windy conditions and is capable of welding thick sections of metal. However, one must exercise care during the welding procedure since the heat produced can lead to warping or distortion of the base materials if not managed correctly.

The Importance of Quality Suppliers

The effectiveness and durability of electrode welding largely depend on the quality of the electrodes used. Therefore, sourcing electrodes from reliable suppliers is paramount. Quality suppliers ensure that their products meet specific industry standards for performance and safety. Suppliers who specialize in electrode products understand the nuances of welding materials, providing a diverse range of electrodes tailored for different metals, thicknesses, and applications.

When selecting a supplier, factors to consider include the quality of the electrodes, the range of products offered, delivery options, and customer service. A reputable supplier should also provide technical support and resources to help customers make informed decisions. Additionally, suppliers with a track record of reliability and positive customer reviews can provide peace of mind in terms of product performance.

Key Types of Electrodes

soldadura de electrodo supplier

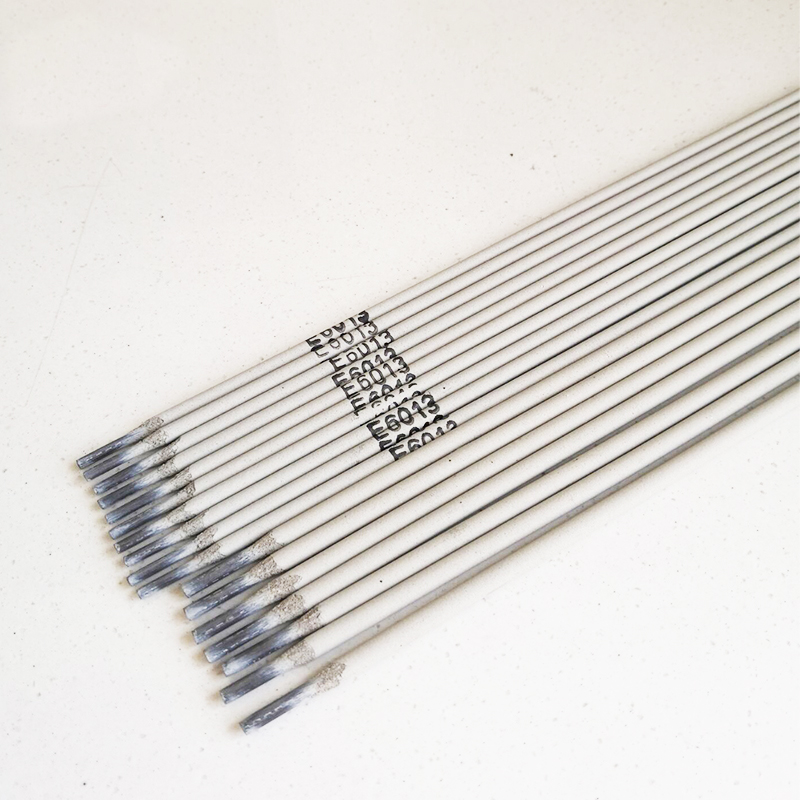

Electrode suppliers offer various types of electrodes to meet the diverse needs of welders

1. E6010 A versatile electrode suitable for various positions and used primarily in pipe welding. 2. E6011 Great for penetrating welds, this electrode can be used on rusted and dirty materials. 3. E6013 Ideal for light to medium penetration and used mainly for general welding purposes. 4. E7018 Known for its low-hydrogen content, this electrode is used for high-strength welds and requires a specific storage condition to maintain its effectiveness.

Each electrode type has unique characteristics that make it suitable for specific applications, and understanding these can significantly enhance welding performance.

Innovations in Electrode Welding

With advancements in technology, the electrode welding process has seen various innovations over the years. Manufacturers are developing electrodes with improved characteristics, such as better arc stability, lower spatter production, and higher deposition rates. Suppliers who stay updated with these innovations ensure that their customers have access to cutting-edge electrode products, thereby improving welding efficiency and overall quality.

Environmental consciousness has also led suppliers to introduce eco-friendly electrodes. These products are designed to minimize toxic emissions during the welding process, aligning with the increasing demand for sustainable welding practices.

Conclusion

In conclusion, the role of electrode welding suppliers cannot be understated. They are crucial to the industry, providing essential materials that ensure the effectiveness and quality of welding operations. By understanding the types of electrodes available and focusing on suppliers that prioritize quality and customer support, welders can achieve superior results in their projects. As the industry continues to evolve, staying informed about innovations in electrode materials and suppliers will be vital for maintaining competitive advantage and operational efficiency. Whether for construction, manufacturing, or repair work, investing in quality electrode welding products is an investment in the strength and longevity of welded structures.

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025

-

Best Stainless Steel Flux Core Wire 030 for Welding – High Strength & Clean WeldsNewsJul.06,2025

-

High-Performance Hard Facing Welding Rod – Durable & Wear-Resistant Electrodes for Industrial UseNewsJul.05,2025

-

Simple Welding Rods – High Quality Arc & Aluminium Welding Rods Wholesale Reliable Stick Welding Rods ManufacturersNewsJul.05,2025

-

3.2mm 7018 Welding Electrode Wholesale Supplier in China Factory Direct Price & High QualityNewsJul.04,2025