Top Manufacturers of Stainless Steel Welding Wire for Durable Fabrication Solutions

The Landscape of Stainless Steel Welding Wire Manufacturers

Stainless steel welding wire is a critical component in various industrial applications, offering strength, durability, and resistance to corrosion. As industries increasingly prioritize quality and efficiency, the demand for high-quality stainless steel welding wires has surged, leading to the growth of numerous manufacturers in this sector. This article explores the landscape of stainless steel welding wire manufacturers, diving into the factors driving this market and the characteristics that define quality welding wires.

Understanding Stainless Steel Welding Wire

Welding wire is a consumable used in welding processes to join metal pieces together. Stainless steel welding wire, specifically, is prized for its unique properties derived from its alloy composition, which includes chromium, nickel, and other elements that enhance its corrosion resistance. The wire is used in various welding techniques, such as MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding, making it versatile for a wide range of applications, including construction, automotive, aerospace, and manufacturing.

Market Demand and Growth Factors

Several factors contribute to the growing demand for stainless steel welding wire. The construction and manufacturing industries are the primary drivers, as they utilize stainless steel for its strength and resistance to rust and oxidation. In particular, the rise in infrastructure projects globally, coupled with an increasing focus on sustainability and environmentally friendly practices, has pushed manufacturers to adopt materials that enhance structural longevity and reduce maintenance costs.

Additionally, technological advancements in welding equipment have fueled the demand for high-quality welding wires. Manufacturers are continuously innovating to develop wires that not only provide superior welds but also improve the efficiency and safety of welding operations. These advancements have led to the introduction of specialized wires designed for specific applications, further broadening the market.

Characteristics of Quality Welding Wires

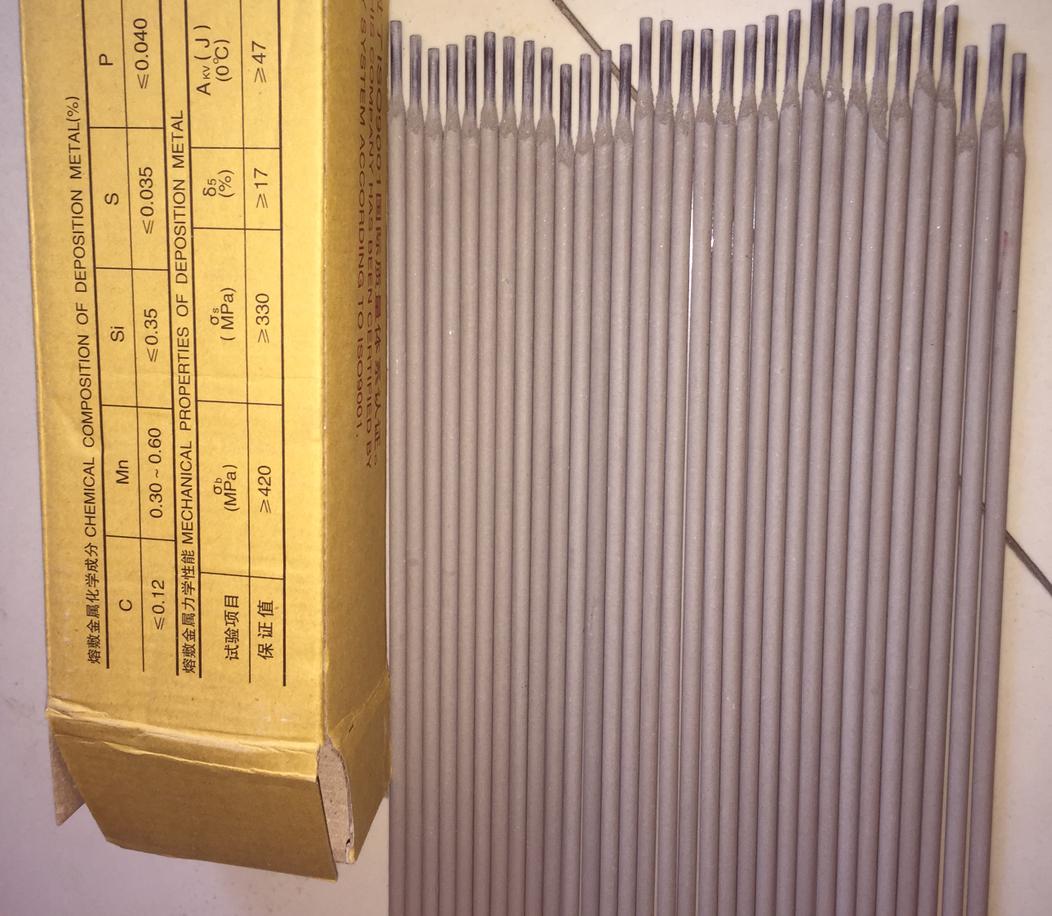

stainless welding wire manufacturers

When selecting stainless steel welding wire, several characteristics determine its quality and suitability for specific applications

1. Composition The alloy composition plays a crucial role in the performance of the welding wire. Quality manufacturers adhere to strict standards regarding the chemical makeup, ensuring that the wire offers optimal corrosion resistance, strength, and flexibility.

2. Diameter The diameter of the welding wire affects the heat input, penetration, and the overall weld quality. High-quality manufacturers provide a range of diameters to cater to different welding needs, allowing for versatility in applications.

3. Packaging and Storage The way welding wire is packaged and stored also impacts its quality. Premium manufacturers focus on protective packaging that prevents contamination and damage, ensuring that the wire maintains its integrity from the factory to the job site.

4. Certifications and Testing Leading manufacturers invest in quality control processes and certifications, such as ISO compliance. Rigorous testing, including tensile strength and corrosion resistance tests, ensures that their products meet industry standards and customer expectations.

Conclusion

The market for stainless steel welding wire is thriving, driven by robust demand across various industries. A plethora of manufacturers are competing to meet this demand, presenting opportunities for innovations and quality improvement. As technology evolves and the need for reliable, durable materials increases, consumers must focus on selecting reputable manufacturers that prioritize quality, compliance, and innovation. By understanding the key characteristics that define superior stainless steel welding wires, industry professionals can make informed choices that enhance the quality of their work and contribute to the longevity of their projects. With sustainability and efficiency at the forefront of industrial practices, the future of stainless steel welding wire manufacturing looks bright.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025