Top Stick MIG Welding Manufacturers for Quality and Performance in 2023

Stick MIG Welding Manufacturers A Comprehensive Overview

Welding is an essential process in various industries, from construction to automotive manufacturing. Among the various welding techniques, Stick and MIG (Metal Inert Gas) welding are two of the most popular methods used today. Both techniques have their unique advantages and applications, and many manufacturers specialize in producing equipment for these processes. In this article, we will explore Stick and MIG welding, the differences between them, and highlight some of the prominent manufacturers in the industry.

Understanding Stick and MIG Welding

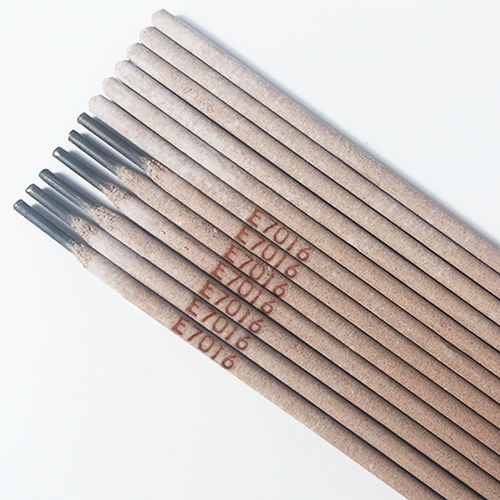

Stick welding, also known as Shielded Metal Arc Welding (SMAW), involves using a consumable electrode coated in flux that creates an arc between the electrode and the workpiece. This process generates heat, melting the electrode and the base material to form a strong weld. Stick welding is well-suited for outdoor applications and can be used on various metals, making it a versatile choice for many professionals.

MIG welding, on the other hand, uses a continuous wire feed as the electrode and an inert gas, usually Argon or CO2, to protect the weld pool from contamination. This method is popular for its speed and ease of use, particularly for thin materials. MIG welding provides a clean, strong weld and is favored in applications where aesthetic appearance matters, such as in automotive bodywork and manufacturing.

Key Differences Between Stick and MIG Welding

The selection between Stick and MIG welding depends on several factors, including material thickness, position, and environmental conditions. Stick welding is more forgiving in windy conditions and can be used in various positions, making it suitable for outdoor projects. However, it requires more skill to master, as maintaining the correct arc length and travel speed is crucial for a good weld.

MIG welding is generally easier to learn and provides a more visually appealing finished product. It is faster than Stick welding, allowing for higher productivity. However, MIG welding equipment can be less portable and may not perform well on rusty or dirty surfaces, where Stick welding excels.

Prominent Stick and MIG Welding Manufacturers

stick mig welding manufacturers

The market for welding equipment is robust, with various manufacturers offering high-quality machines for both Stick and MIG welding

. Some of the leading names in the industry include1. Lincoln Electric A pioneer in the welding industry, Lincoln Electric offers a wide range of Stick and MIG welders. Their products are known for their durability and advanced technology, catering to both professional and amateur welders.

2. Miller Electric Miller Electric is renowned for its innovative welding equipment and has a strong reputation for reliability. Their MIG and Stick welding machines are used in various applications, from heavy industrial work to small workshops.

3. ESAB With a long history in the welding industry, ESAB provides a diverse range of welding solutions. Their Stick and MIG welders are recognized for their performance and efficiency, making them a popular choice among professionals.

4. Hobart Welders Specializing in both MIG and Stick welding, Hobart offers user-friendly machines that are particularly appealing to hobbyists and small business owners. Their equipment is designed for versatility and reliability.

5. Everlast Welders A newer player in the market, Everlast Welders focuses on providing high-quality, cost-effective welding solutions. Their Stick and MIG welders offer advanced features at competitive prices, making them an attractive option for budget-conscious buyers.

Conclusion

Stick and MIG welding are two essential techniques with distinct characteristics and applications. The choice between them largely depends on the specific requirements of the project at hand. As the demand for quality welding equipment continues to grow, manufacturers like Lincoln Electric, Miller Electric, ESAB, Hobart, and Everlast remain at the forefront, providing skilled welders with the tools they need to create strong, reliable welds. Understanding the capabilities of both methods and the available equipment is crucial for anyone looking to excel in the field of welding.

-

E71TGS Welding Wire High-Strength Flux Core for Durable JointsNewsMay.20,2025

-

High-Strength 3/4 Welding Rod 7016 for Pipe Welding China SupplierNewsMay.20,2025

-

71T1 Flux Cored Wire High-Performance 1.2mm Welding SolutionsNewsMay.20,2025

-

3.25mm Welding Electrodes High-Performance, Durable Wholesale FactoryNewsMay.19,2025

-

AWS A5.1 E6010 Welding Rods Durable All-Position ElectrodesNewsMay.19,2025

-

Wholesale E6013 Welding Electrodes Factories Durable & AffordableNewsMay.18,2025