welding electrode 7018 factories

An Overview of 7018 Welding Electrodes Factories and Production

Welding is an integral process in various industries, from construction to manufacturing, where joining metals is critical for structural integrity and performance. Among the myriad of welding electrodes available, the 7018 welding electrode stands out due to its favorable properties, making it a preferred choice for many welders. In this article, we’ll delve into the features of 7018 welding electrodes, their applications, and the factories dedicated to their production.

What are 7018 Welding Electrodes?

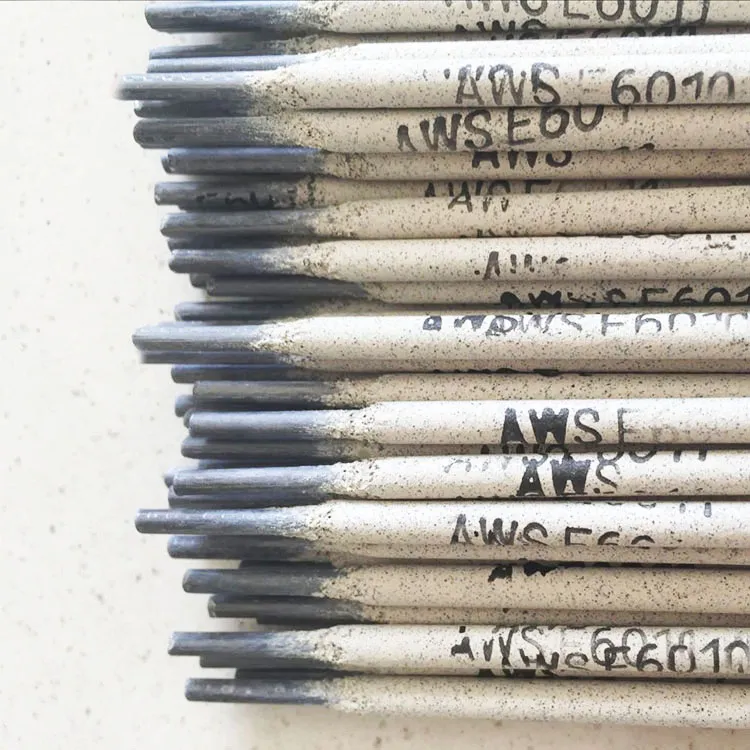

The 7018 welding electrode is classified as a low hydrogen electrode, often used in shielded metal arc welding (SMAW). The designation 7018 refers to specific characteristics the 70 indicates a minimum tensile strength of 70,000 psi, the 1 signifies that it is suitable for all position welding, and the 8 denotes that it has low hydrogen content, which minimizes the risk of hydrogen-induced cracking in the weld joint.

These electrodes are typically coated with a mix of iron powder and potassium compounds, which contribute to the stability of the arc and the quality of the weld. Their low hydrogen content is especially crucial when welding high-strength steels, ensuring good ductility and resilience in the completed weld.

Applications of 7018 Electrodes

7018 electrodes are commonly used in various applications, particularly in structures that require high strength and toughness, such as bridges, pressure vessels, and large structural components. They are often employed in the fabrication and repair of heavy machinery, pipelines, and shipbuilding. The versatility of the 7018 electrode allows it to be used on both thick and thin materials, and its ability to produce smooth, aesthetically pleasing welds makes it favorable for automotive and residential projects.

In addition, the all-position capability of the 7018 electrode means it can be utilized effectively in vertical and overhead positions, which is essential in various construction and manufacturing scenarios.

Factories Producing 7018 Electrodes

welding electrode 7018 factories

The production of 7018 welding electrodes takes place in specialized factories around the world, designed to meet stringent quality control standards. The manufacturing process involves several key steps raw material selection, formulation of the coating, welding core preparation, coating application, and quality inspections.

1. Raw Material Selection Quality steel wire ensures excellent mechanical properties in the final product. The raw materials need to be of high purity to prevent any impurities that may affect weld integrity.

2. Coating Formulation The coating formulation is critical. The producers must carefully mix iron powder, flux, and stabilizers. This process requires advanced blending technology to ensure uniform distribution and performance of the coating.

3. Welding Core Preparation The wire used for the core must be precisely drawn to the correct diameter, typically ranging from 1/16 to 5/32 inches. This stage is crucial for maintaining consistency in electrical conductivity and mechanical strength.

4. Coating Application The core is coated using extrusion or dipping methods. Proper curing and drying are essential to ensure that the coating adheres firmly and exhibits low hydrogen characteristics.

5. Quality Control Factories conduct rigorous quality tests, including tensile strength tests, metallography, and moisture content determination, to ensure that the electrodes meet the required specifications.

Conclusion

In conclusion, 7018 welding electrodes represent a vital component in the world of welding, applauded for their strength, versatility, and low hydrogen properties. The factories that produce these electrodes play a significant role in ensuring that they are made to the highest standards, meeting the demands of various industries. With advancements in technology and manufacturing processes, the quality of 7018 electrodes continues to improve, further solidifying their position as a go-to choice for welders around the globe. The ongoing development in this field promises even greater efficiency and performance in welding applications for the future.

-

E7016 Welding Rods: High Strength Low Hydrogen for Critical WeldsNewsAug.29,2025

-

E71T-11 Flux Core Wire: Premium Gasless Welding SolutionNewsAug.28,2025

-

Premium Carbon Rods for Welding | Stable Arc & Precise GougingNewsAug.27,2025

-

Carbon Steel Welding Wire: Superior Strength & PrecisionNewsAug.26,2025

-

AWS E6013 Welding Electrodes: All-Position & Smooth Arc RodsNewsAug.25,2025

-

E312 Electrode: High Strength Welding Rod for Dissimilar MetalsNewsAug.24,2025