Wholesale Manufacturers of TIG, MIG, and Stick Welding Equipment and Supplies

Exploring the World of Wholesale TIG, MIG, and Stick Welding Manufacturing

Welding is an essential process in a myriad of industries, ranging from construction and automotive manufacturing to aerospace and shipbuilding. Among the various methods of welding, TIG (Tungsten Inert Gas), MIG (Metal Inert Gas), and Stick welding (Shielded Metal Arc Welding) stand out due to their unique characteristics and applications. As a significant sector within the manufacturing landscape, wholesale TIG, MIG, and Stick welding brings together technology, precision, and efficiency to meet the myriad demands of the marketplace.

Understanding Welding Techniques

Before delving into the wholesale aspect, it's vital to understand each welding technique's basic principles and advantages.

1. TIG Welding This method uses a non-consumable tungsten electrode to produce the weld. It is known for its ability to create high-quality, precise welds on thin materials. TIG welding requires a high level of skill, as the welder must control both the heat and the filler material simultaneously. This technique is often used for stainless steel, aluminum, and other non-ferrous metals.

2. MIG Welding MIG welding, on the other hand, employs a continuously fed wire electrode and gas to shield the weld pool. This method is faster than TIG welding and is suitable for thicker materials. MIG welding is commonly used in industrial applications and is appreciated for its ease of use, making it a popular choice among novice welders and professionals alike.

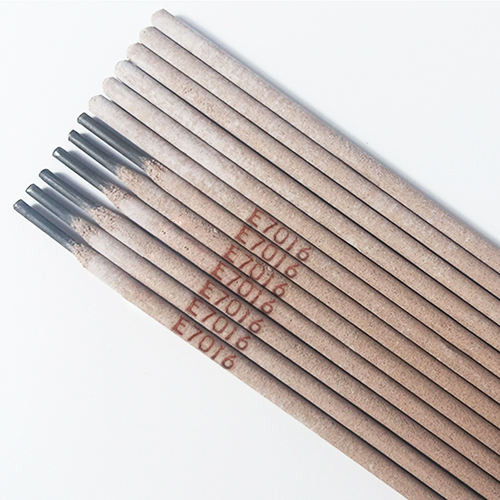

3. Stick Welding Also known as Shielded Metal Arc Welding (SMAW), Stick welding is one of the oldest and simplest welding processes. It uses a consumable electrode coated in flux to create the weld. While it may not offer the precision of TIG welding or the speed of MIG, Stick welding is robust and can be used in outdoor conditions or on rusty or dirty metals. This versatility makes it a go-to choice in construction and repair sectors.

The Role of Wholesale Manufacturers

In the wholesale marketplace, manufacturers of TIG, MIG, and Stick welding equipment play a pivotal role in ensuring the availability and quality of welding products

. These manufacturers not only produce the welding machines and electrodes but also provide essential accessories such as safety gear, gas supplies, and filler materials.wholesale tig mig and stick welding manufacturer

Wholesale manufacturers benefit from economies of scale, allowing them to reduce costs and offer competitive prices to their customers—whether they are retailers, large industrial clients, or smaller shops. The need for high-quality welding equipment is ever-increasing as industries continue to expand and innovate. Manufacturers are thus tasked with keeping up with technological advancements and meeting stringent safety and quality standards.

Technological Advancements in Welding

As with many sectors, technology drives significant advancements within welding manufacturing. Modern welding machines now incorporate sophisticated digital controls and automation features, enhancing efficiency and precision. Some manufacturers have introduced inverter technology that allows machines to be lighter and more energy-efficient without sacrificing power.

Furthermore, the integration of welding simulation software enables welders to practice and perfect their technique without the cost and waste associated with materials. This not only enhances skill levels but also reduces the occurrence of errors during actual welding projects.

The Demand for Quality

In a globalized market, the demand for high-quality welding equipment remains strong. Industries require reliable and durable products that can sustain harsh working conditions and produce excellent results. Wholesale manufacturers focus on quality control, ensuring that their products meet international standards, which is critical for maintaining trust and ensuring safety in welding applications.

Conclusion

Wholesale TIG, MIG, and Stick welding manufacturing is a dynamic and essential facet of the welding industry. As technology advances and industries evolve, the importance of skilled manufacturers who can provide high-quality equipment and training will only grow. In a competitive landscape, those who adapt to changing technologies and labor demands will thrive, ensuring that the welding industry continues to forge ahead, bonding and shaping the future. Whether for construction, automotive, or any other industry, the role of wholesale welding manufacturers remains crucial in supporting the backbone of modern infrastructure and innovation.

-

E71T-11 Flux Core Wire: Premium Gasless Welding SolutionNewsAug.28,2025

-

Premium Carbon Rods for Welding | Stable Arc & Precise GougingNewsAug.27,2025

-

Carbon Steel Welding Wire: Superior Strength & PrecisionNewsAug.26,2025

-

AWS E6013 Welding Electrodes: All-Position & Smooth Arc RodsNewsAug.25,2025

-

E312 Electrode: High Strength Welding Rod for Dissimilar MetalsNewsAug.24,2025

-

J506 Welding Rod: High-Strength, Crack-Resistant ElectrodeNewsAug.23,2025