Wholesale Suppliers for CO2 Welding Wires at Competitive Prices

Wholesale CO2 Welding Wires Suppliers Meeting Industry Demands

The welding industry plays a crucial role in various sectors, including construction, manufacturing, and automotive. Among the essential components of the welding process is the choice of appropriate welding wire, specifically CO2 (carbon dioxide) welding wires. These wires are widely recognized for their efficiency and effectiveness in delivering high-quality welding results. In recent years, there has been a significant increase in demand for wholesale suppliers of CO2 welding wires, driven by rapid industrial growth and technological advancements.

The Importance of CO2 Welding Wires

CO2 welding wires are primarily used in the gas metal arc welding (GMAW) process, where carbon dioxide serves as the shielding gas. One of the main advantages of using CO2 as a shielding gas is its cost-effectiveness compared to other gases like argon or mixed gas. This makes CO2 welding an attractive option for many businesses looking to optimize their operational costs while maintaining quality. CO2 welding wires provide excellent penetration, reduced spatter, and can effectively weld a variety of materials, making them about versatile for different applications.

The benefits of CO2 welding wires go beyond just cost savings. The wires are particularly useful in joining thicker materials due to their higher deposition rates, which contributes to faster productivity on job sites. Additionally, CO2 welding wires enable better heat control, which is critical in preventing warping and distortion of the welded materials.

The Growing Demand for Wholesale Suppliers

As industries expand and new projects emerge worldwide, the demand for quality welding materials, especially CO2 welding wires, is on the rise. Wholesale suppliers are essential in this dynamic marketplace, offering bulk purchasing options that can significantly reduce costs for manufacturers and contractors. These suppliers cater to various sectors, from small welding shops to large-scale manufacturers, ensuring that they have a steady supply of quality welding wires to meet their project's needs.

In recent years, many wholesale CO2 welding wire suppliers have emerged, driven by the increasing competition and the need to meet stringent quality standards. Suppliers are now focused not only on the quantity of wire but also on enhancing the quality of their products. The industry has seen an emphasis on sourcing high-grade materials and adopting advanced manufacturing techniques, ensuring that the welding wires meet the requirements for high-quality performance.

Factors to Consider When Choosing a Supplier

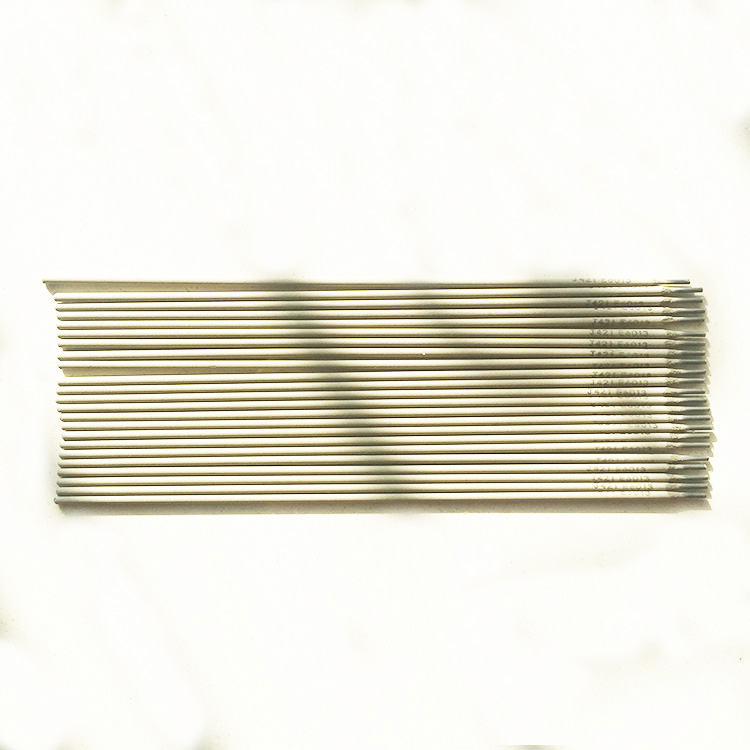

wholesale welding wires co2 suppliers

When selecting a wholesale CO2 welding wire supplier, several factors need to be considered to ensure that businesses receive the best possible products and services.

1. Quality Assurance The purity of the alloy and consistency in the manufacturing process are vital for producing reliable welding wires. Suppliers should provide detailed information about their quality control processes and certifications to guarantee product quality.

2. Range of Products A good wholesale supplier should offer a wide range of CO2 welding wires, including different diameters and materials, to cater to various welding applications. This ensures that companies can find the right wire for their specific needs without having to rely on multiple suppliers.

3. Pricing and Bulk Discounts Competitive pricing is crucial in the wholesale market. Suppliers should offer transparent pricing structures and bulk discounts to make purchasing more affordable for businesses.

4. Customer Support Excellent customer service is vital, especially when dealing with technical inquiries or concerns about product specifications. A reputable supplier should provide prompt responses and knowledgeable support to assist their clients effectively.

5. Reliable Delivery Timely delivery of products is essential to avoid disruptions in project timelines. Suppliers should have solid logistics systems in place to ensure that orders are fulfilled promptly.

Conclusion

The demand for wholesale CO2 welding wire suppliers is growing as industries evolve and project requirements change. With the advantages of cost-effectiveness, versatility, and high-quality results, CO2 welding wires continue to be a preferred choice in numerous applications. Selecting the right wholesale supplier can significantly impact a business's efficiency and success within the welding industry, making it essential to consider various factors before making a decision. As the industry grows, suppliers that focus on quality, customer service, and sustainability will undoubtedly thrive, shaping the future of welding practices globally.

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025