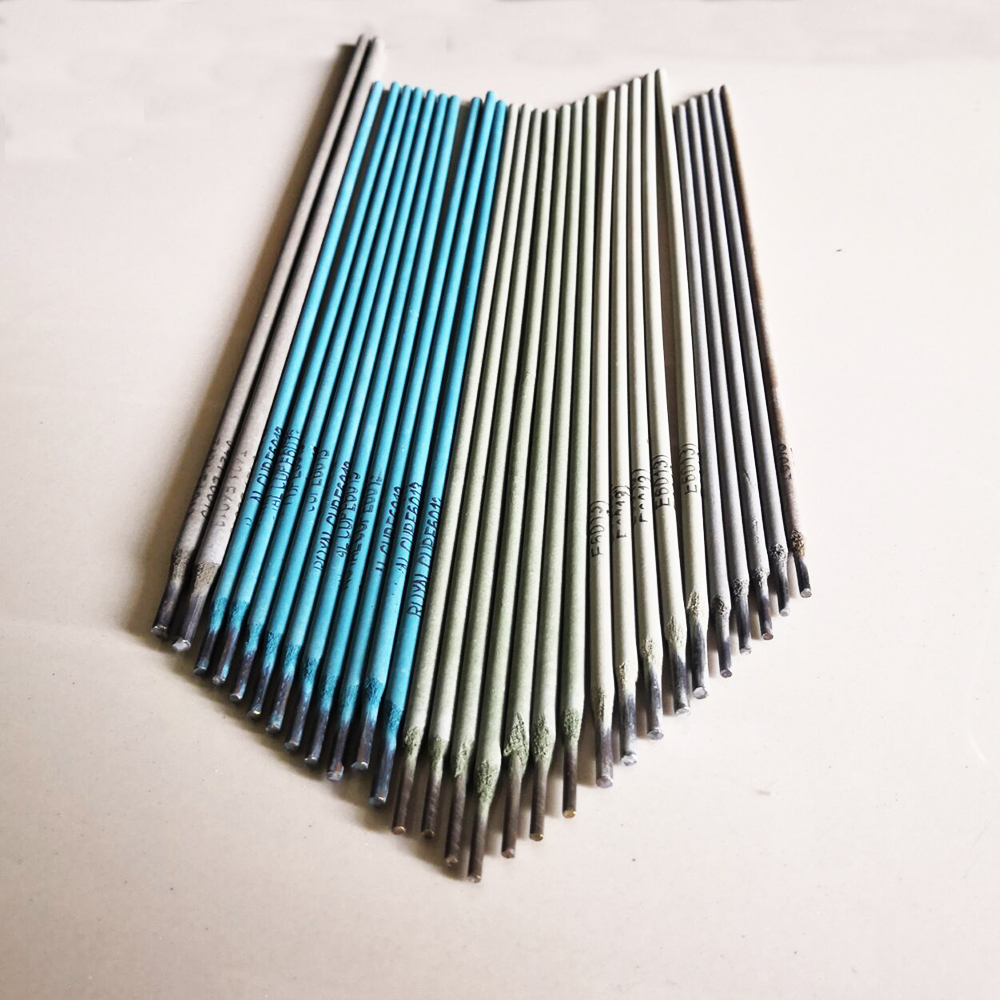

3.2mm welding rods factory

The Significance of 3.2mm Welding Rods Manufacturing Insights

In the world of welding, choosing the right materials is crucial for achieving strong, durable, and reliable joins. Among the various welding rods available, 3.2mm welding rods stand out due to their versatility and effectiveness in a wide range of applications. This article explores the manufacturing process of 3.2mm welding rods and their significance in industrial and construction settings.

Understanding Welding Rods

Welding rods are metallic rods used in the welding process to create a strong bond between two or more materials, typically metals. The diameter of the rod affects the amount of metal deposited during welding and plays a critical role in the overall strength and quality of the weld. The 3.2mm size is particularly popular among welders because it strikes an ideal balance between control and efficiency, allowing for precise welds on various steel thicknesses.

Manufacturing Process

The production of 3.2mm welding rods involves several key stages, ensuring that the final product meets industry standards for quality and performance.

1. Raw Material Selection The first step is selecting high-quality raw materials, typically low-carbon steel, which provides excellent weldability. The composition of the metal is carefully chosen to enhance the mechanical properties of the welding rod.

3.2mm welding rods factory

2. Wire Drawing The selected steel is then subjected to wire drawing, a process that reduces the diameter of the steel wire to the desired dimension of 3.2mm. This method not only shapes the wire but also increases its tensile strength through cold working.

3. Coating Application After achieving the desired diameter, the welding rods need to be coated with a suitable flux material. This coating protects the weld pool from contaminants during the welding process and aids in the stability of the arc. Common coatings include cellulose, rutile, and basic flux formulations, each providing different characteristics suited for various welding tasks.

4. Cutting and Packaging The rods are then cut to specific lengths, often around 300mm or more, depending on the intended use. After cutting, the rods are bundled and packaged for distribution, ensuring they remain protected from moisture and pollutants during transportation.

Applications of 3.2mm Welding Rods

3.2mm welding rods are extensively used across various sectors, including automotive, construction, and heavy machinery. They are ideal for welding mild steel, stainless steel, and other alloys, making them suitable for both structural and fabrication tasks. The ease of use and flexibility make them a preferred choice among both novice and experienced welders.

Conclusion

The manufacturing of 3.2mm welding rods is a well-defined process that emphasizes quality and precision at every step. As a fundamental tool in welding, these rods play a critical role in creating strong and resilient structures. With advancements in technology and materials science, the future of welding rods, including the 3.2mm size, continues to evolve, promising even greater performance for welders around the world. Whether in a factory setting or on a construction site, the significance of 3.2mm welding rods will undoubtedly remain vital in the field of metal joining.

-

Premium ENiFe-Ci Welding Rods - Durable & Wholesale SupplierNewsJun.06,2025

-

High-Quality 1.6mm Stainless Steel Arc Welding Rods Durable & Corrosion ResistantNewsJun.06,2025

-

Premium E6013 Electrode Chemical Composition ExplainedNewsJun.06,2025

-

Top Quality ER70S-6 Welding Wire High-Strength & ReliableNewsJun.06,2025

-

Premium 2.5 Welding Rods for Aluminium Arc Welding Wholesale SupplierNewsJun.06,2025

-

MINIMIG 100E Flux Core Welder Easy Aluminum Welding SolutionNewsJun.05,2025