Feb . 04, 2025 02:47

Back to list

aws 7018 welding rod

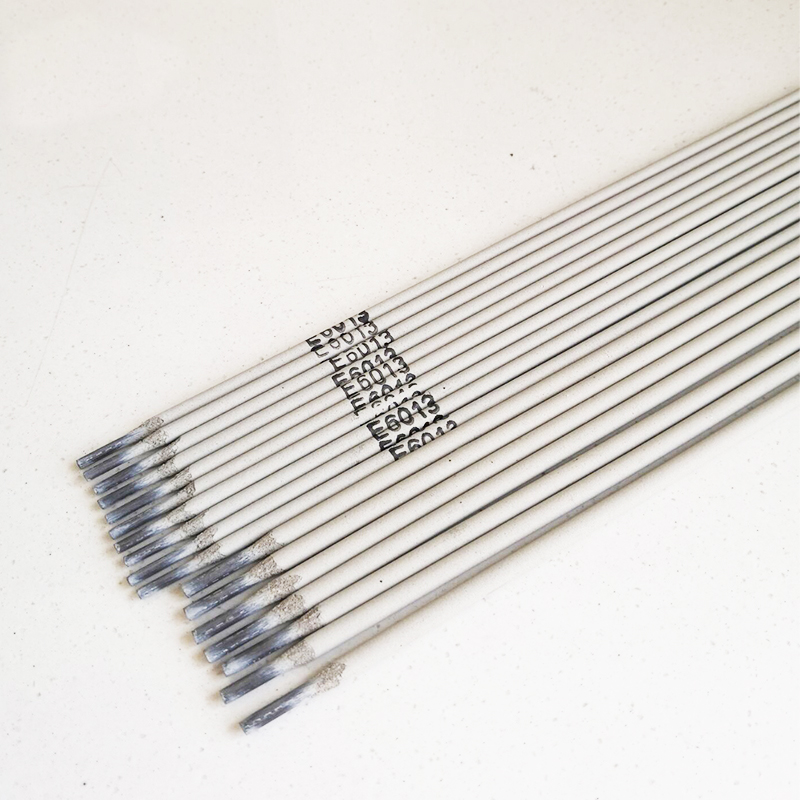

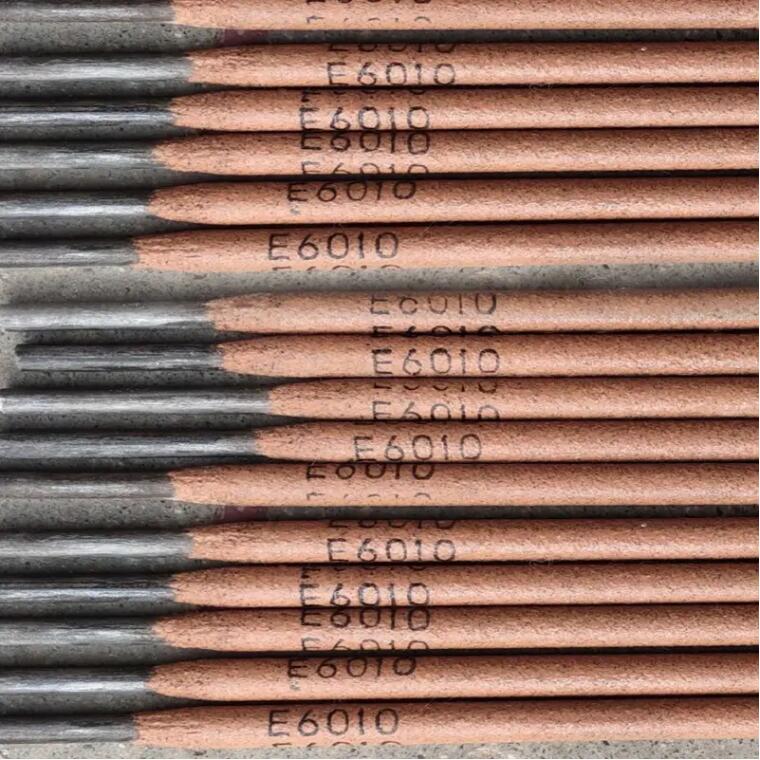

Stick welding, also known as Shielded Metal Arc Welding (SMAW), is a versatile and widely used method for fusing metals. When it comes to selecting the right tools for stick welding, the 7018 welding rod is often hailed as a favorite among professionals due to its reliability and performance. Offering a comprehensive view of the 7018 stick welding rod, this article combines expert insights, practical experience, and reliable advice to help you make informed decisions.

The learning curve for stick welding with a 7018 rod can be steep for beginners, but persistence pays off. Welders familiar with the process understand the significance of maintaining a short arc length and the correct travel speed. These elements are key to preventing common welding defects such as slag inclusion and undercutting. As one becomes more adept, the ability to produce sound, defect-free welds becomes second nature. For those aiming to enhance their stick welding skills, understanding the relationship between amperage settings and electrode size is crucial. Larger electrodes typically require higher amperage settings, while smaller rods operate efficiently at lower levels. Balancing these settings can significantly affect the weld quality and overall efficiency. In terms of applications, the robust characteristics of the 7018 make it indispensable in critical welding scenarios. It is widely employed in the fabrication of bridges, pipelines, and heavy machinery, where weld integrity is non-negotiable. Welders entrusted with such projects often rely on the 7018's reliability, ensuring the structures meet safety and performance standards. Despite its advantages, the 7018 rod is not entirely without challenges. Welders must address the potential for porosity, especially if the rods are not stored properly or exposed to moisture. Regular inspection of the rods and adherence to recommended storage practices are essential to mitigate such risks. In conclusion, the 7018 stick welding rod stands out as a pillar in the welding community for its ability to deliver consistent, strong, and aesthetically pleasing welds across various applications. Its success lies in a combination of professional knowledge, practical skills, and meticulous handling. As welders continue to perfect their techniques with the 7018, they contribute to safer, more reliable, and longer-lasting constructions. Whether you're a seasoned professional or a novice eager to learn, the insights garnered from using the 7018 can significantly enhance your welding prowess.

The learning curve for stick welding with a 7018 rod can be steep for beginners, but persistence pays off. Welders familiar with the process understand the significance of maintaining a short arc length and the correct travel speed. These elements are key to preventing common welding defects such as slag inclusion and undercutting. As one becomes more adept, the ability to produce sound, defect-free welds becomes second nature. For those aiming to enhance their stick welding skills, understanding the relationship between amperage settings and electrode size is crucial. Larger electrodes typically require higher amperage settings, while smaller rods operate efficiently at lower levels. Balancing these settings can significantly affect the weld quality and overall efficiency. In terms of applications, the robust characteristics of the 7018 make it indispensable in critical welding scenarios. It is widely employed in the fabrication of bridges, pipelines, and heavy machinery, where weld integrity is non-negotiable. Welders entrusted with such projects often rely on the 7018's reliability, ensuring the structures meet safety and performance standards. Despite its advantages, the 7018 rod is not entirely without challenges. Welders must address the potential for porosity, especially if the rods are not stored properly or exposed to moisture. Regular inspection of the rods and adherence to recommended storage practices are essential to mitigate such risks. In conclusion, the 7018 stick welding rod stands out as a pillar in the welding community for its ability to deliver consistent, strong, and aesthetically pleasing welds across various applications. Its success lies in a combination of professional knowledge, practical skills, and meticulous handling. As welders continue to perfect their techniques with the 7018, they contribute to safer, more reliable, and longer-lasting constructions. Whether you're a seasoned professional or a novice eager to learn, the insights garnered from using the 7018 can significantly enhance your welding prowess.

Previous:

Next:

Latest news

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025