Suppliers of Arc Welding Rods for All Your Welding Needs

The Role of Arc Welding Rods Suppliers in Modern Industries

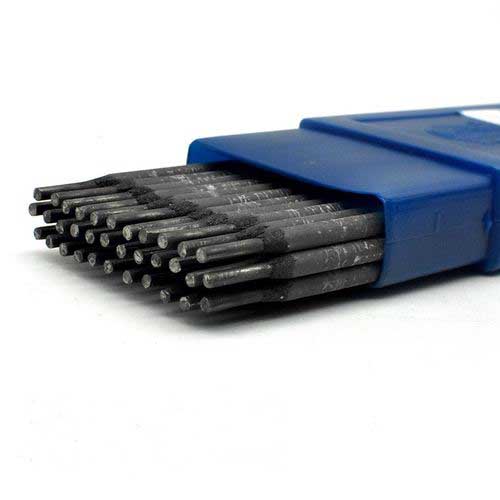

Arc welding is a fundamental process used across various industries, from construction to automotive manufacturing. Central to this process is the use of welding rods, which are essential for creating strong, durable welds. This article explores the significance of arc welding rod suppliers and how they contribute to the efficiency and effectiveness of welding operations.

Arc welding rods, also known as electrodes, serve multiple purposes. They provide the filler material needed to create a weld joint, and they also play a crucial role in stabilizing the arc during the welding process. The choice of welding rod can vastly affect the quality of the weld, making it imperative for welders and manufacturers to source their rods from reliable suppliers.

The Role of Arc Welding Rods Suppliers in Modern Industries

Moreover, experienced suppliers can offer a wide range of products to meet diverse industry demands. This variety includes different types of rods, such as E6011, E7018, and E308L, each with distinct properties suited for specific welding tasks. A good supplier keeps up with industry trends and technological advancements, ensuring that customers have access to the latest innovations designed to improve welding outcomes.

arc welding rods suppliers

In addition to product quality, suppliers play a critical role in the supply chain. They ensure that welding rods are readily available, helping manufacturers avoid delays in production. A dependable supplier can significantly reduce lead times by maintaining adequate stock levels and being proactive about reordering products. This reliability is especially crucial in industries where projects are time-sensitive and unanticipated shortages can cause significant operational setbacks.

Furthermore, knowledgeable suppliers often provide additional value through customer support and technical assistance. Whether it’s recommending the right rod for a specific application or providing training on welding techniques, these services can be invaluable. Companies that partner with suppliers who offer comprehensive support can enhance their operational efficiency and ensure that their workforce is skilled and well-equipped.

Choosing the right arc welding rod supplier can also have economic benefits. By procuring high-quality rods at competitive prices, companies can optimize their production costs. Additionally, reliable suppliers often have established relationships with manufacturers, allowing them to negotiate better deals and pass those savings on to their customers.

To summarize, arc welding rod suppliers are vital players in the welding industry, providing essential products and services that enhance the quality and efficiency of welding operations. Their role extends beyond just supplying materials; they offer expertise, reliability, and support that are crucial for the success of welding projects. By selecting the right suppliers, businesses can ensure that they achieve optimal outcomes in their welding endeavors, ultimately leading to stronger, more resilient structures and products in our modern world.

-

E71T-1 Shielding Gas for Gas Shielded Cored Wire Welding SolutionsNewsJul.22,2025

-

Premium Submerged Arc Welding Wire | Efficient Quality SolutionNewsJul.21,2025

-

Premium Solid MIG Welding Wire - Strong, Low-Spatter WeldsNewsJul.21,2025

-

E71T-GS Self-Shielding Welding Wire | Gasless Outdoor UseNewsJul.20,2025

-

E312 Welding Electrode - High Corrosion Resistance & All-Purpose UseNewsJul.20,2025

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025