Factories Producing China 309L 16 Welding Rods for High-Quality Applications

Exploring China's 309L 1.6 Welding Rod Factories

Welding is a critical process in numerous industries, including construction, automotive, manufacturing, and shipbuilding. In this context, China has emerged as a global leader in the production of welding consumables, especially stainless steel welding rods. Among these, the 309L 1.6 welding rod is gaining considerable attention due to its unique properties and essential applications.

Understanding 309L Welding Rods

The 309L welding rod is a type of stainless steel filler material used in welding applications where the base metals are primarily stainless steel. The 309 designation refers to the chemical composition of the rod, which includes a balanced mix of chromium and nickel to ensure excellent corrosion resistance and strength. The “L” indicates that the carbon content is low, which minimizes the risk of weld decarburization and provides improved corrosion resistance and toughness.

Typically, the 1.6 mm diameter of these rods makes them suitable for various welding techniques, including TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding. The applications of 309L rods include joining dissimilar metals, overlay welding, and cladding processes, further establishing their importance in industries where both corrosion resistance and temperature stability are paramount.

The Role of Chinese Factories

China's prominence in the welding rod industry can be attributed to several factors, including advanced manufacturing technologies, a vast labor force, and a strong supply chain. Factories across the country are equipped with state-of-the-art machinery to produce 309L welding rods that meet international standards, ensuring consistency and reliability in their products.

Chinese manufacturers are often leaders in research and development within the welding consumables sector. They invest significantly in improving the quality of their welding rods, including the development of new alloys and refining production techniques. For instance, by optimizing the manufacturing process to control the composition and properties of the welding rod, factories can produce rods that are not only higher in quality but also more cost-effective for consumers. This focus on quality is vital, especially when catering to the global market where standards are stringent.

china 309l 16 welding rod factories

Quality Standards and Certifications

To ensure that their products can compete on a global scale, many Chinese welding rod manufacturers obtain certifications from internationally recognized organizations such as the American Welding Society (AWS) and the International Organization for Standardization (ISO). These certifications confirm that the products meet specific mechanical and chemical property requirements, thus appealing to foreign clients who demand reliability in quality.

Moreover, quality control is rigorously maintained throughout the manufacturing process. From the selection of raw materials to the final inspection of finished products, each step is carefully monitored. This commitment to quality not only enhances the reputation of Chinese firms but also increases customer confidence in products like the 309L welding rods.

Market Trends and Future Prospects

The demand for 309L 1.6 welding rods continues to grow as industries strive for better materials that offer improved performance and durability. As economies worldwide recover and invest in infrastructure, the need for reliable welding solutions is likely to expand, leading to more business opportunities for Chinese factories.

Furthermore, with the increasing focus on sustainability, there is a trend to develop eco-friendly welding rods. Research into alternative materials and processes that reduce emissions during manufacturing is underway. This shift could position Chinese manufacturers as innovators in both traditional and green technologies.

Conclusion

In conclusion, China's 309L 1.6 welding rod factories exemplify how a combination of technology, quality control, and innovation can lead to significant advancements in industrial materials. The unique properties of the 309L welding rods position them as a critical component in various applications across diverse industries. As the global demand for these materials rises, Chinese manufacturers are well-equipped to meet this challenge, ensuring their ongoing role as key players in the international market for welding consumables. With a commitment to quality and continuous improvement, these factories are set to shape the future of welding technology and its applications globally.

-

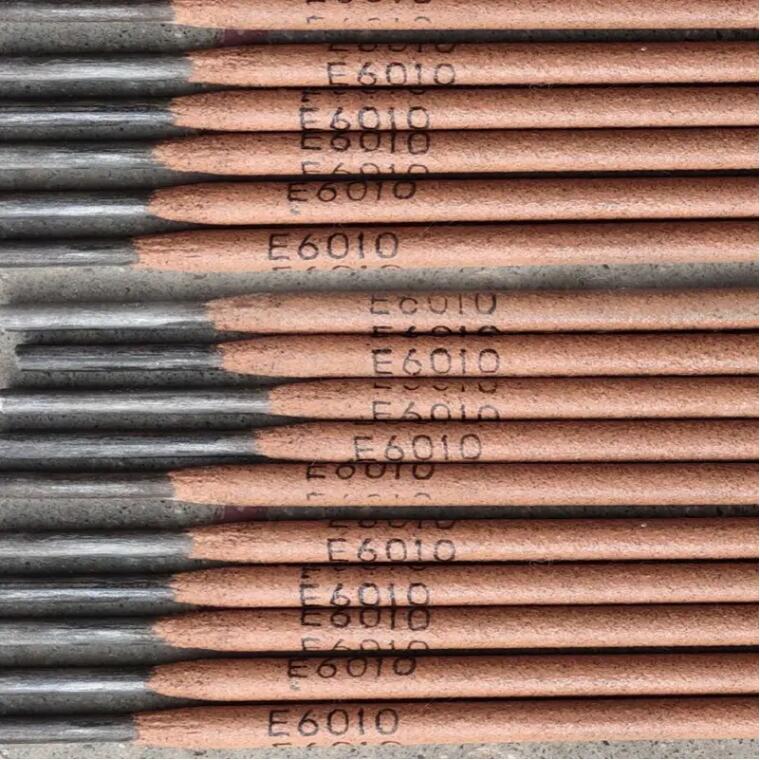

High-Performance Cellulose Electrode E6010 for Steel WeldingNewsJul.28,2025

-

High Quality E71T-11 Welding Wire from China – Flux Cored, Easy to UseNewsJul.28,2025

-

High-Quality SG2 Welding Wire for Superior PerformanceNewsJul.27,2025

-

E6011 Welding Rod for Arc Welding – High Performance & VersatilityNewsJul.26,2025

-

Welding Rod 2.0 mm for Structural Welding - High Strength & PrecisionNewsJul.25,2025

-

Factory Supply Cast Iron Welding Rods AWS ENi-CI High StrengthNewsJul.24,2025