china co2 mig wire factory

The Growth of CO2 MIG Wire Factories in China

In recent years, China's manufacturing sector has witnessed impressive growth, particularly in the production of welding materials such as CO2 MIG (Metal Inert Gas) wires. Known for its efficiency and versatility, CO2 MIG welding is widely used in various industries, including automotive, construction, and shipbuilding. The rise of CO2 MIG wire factories in China reflects not just the increasing demand for welding materials but also the country’s broader commitment to enhancing its industrial capabilities.

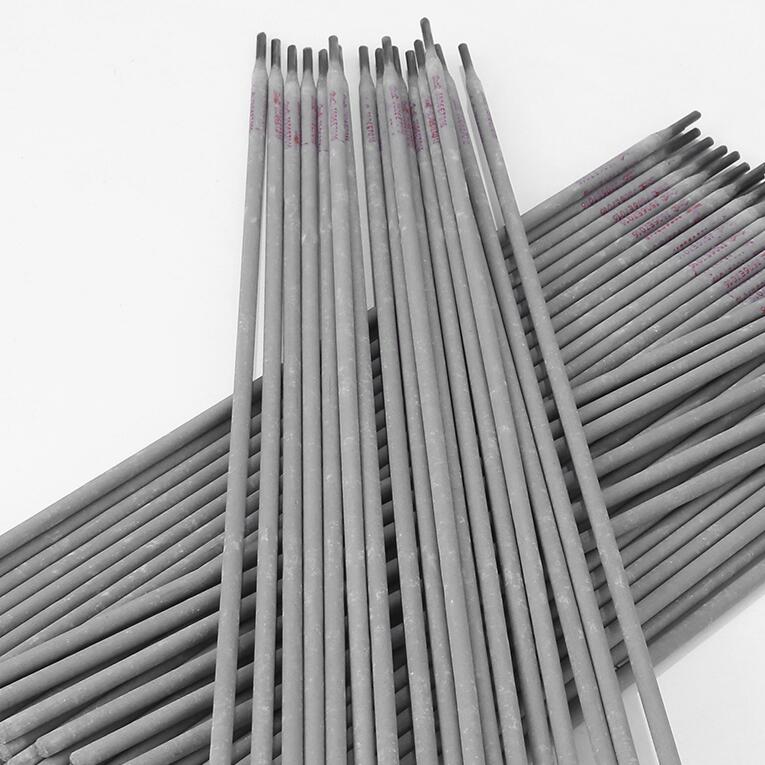

CO2 MIG welding is favored for its ability to produce strong welds on a multitude of materials, including steel and stainless steel. This welding method employs a continuous solid wire electrode fed through a welding gun, which is shielded by a mixture of gases, primarily carbon dioxide. This process not only enhances the quality of welds but also improves productivity, making it a popular choice for manufacturers.

The Growth of CO2 MIG Wire Factories in China

Moreover, the Chinese government has been actively supporting the welding industry through favorable policies and investments. The implementation of technology upgrades in manufacturing processes and increased funding for research and development has stimulated innovation. As a result, many factories are focusing on producing CO2 MIG wires with enhanced performance characteristics, such as improved mechanical properties and corrosion resistance. This push for innovation has not only allowed factories to meet domestic needs but has also positioned them as competitive players in the global market.

china co2 mig wire factory

In terms of environmental considerations, Chinese CO2 MIG wire factories are increasingly adopting sustainable practices. As the world moves toward greener manufacturing processes, many factories are implementing measures to reduce carbon emissions and waste. This not only complies with international standards but also addresses the growing consumer demand for environmentally friendly products. These changes are crucial as they align with China's broader environmental objectives and commitment to sustainable industrial growth.

One of the significant advances in CO2 MIG wire production is the development of high-speed production lines. These lines utilize cutting-edge technology to enhance efficiency and reduce production costs. As factories streamline their operations, they can produce CO2 MIG wires at a lower price point, making them more accessible to various industries. This competitive pricing strategy has also facilitated the export of CO2 MIG wires to international markets, further enhancing China's role as a leading manufacturer.

Additionally, the establishment of strict quality control measures in these factories has elevated the standards of CO2 MIG wires produced in China. Through rigorous testing and quality assurance processes, manufacturers can ensure that their products meet international specifications, building trust among clients both domestically and abroad. This focus on quality is critical in establishing long-term partnerships and gaining a stronger foothold in the global welding supply market.

In conclusion, the expansion of CO2 MIG wire factories in China embodies the country’s industrial evolution and commitment to meeting growing market demands. With increasing investment in technology, sustainable practices, and stringent quality controls, these factories are not only satisfying domestic needs but also making significant inroads into global markets. The future of CO2 MIG wire production in China appears promising, with a solid foundation laid for continued growth and innovation in the years to come. As industries worldwide continue to embrace advanced welding technologies, China's position as a leading supplier of CO2 MIG wires looks set to strengthen further, marking an exciting chapter in the global manufacturing landscape.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025