China Factories for TIG MIG and Stick Welding Equipment and Solutions

The Rise of China’s Welding Industry Focus on TIG, MIG, and Stick Welding Factories

In recent years, China has established itself as a global powerhouse in manufacturing, and this includes the welding sector. Among the various welding techniques, Tungsten Inert Gas (TIG), Metal Inert Gas (MIG), and Stick welding have garnered significant attention due to their versatility and application across multiple industries. This article explores the landscape of TIG, MIG, and Stick welding factories in China, highlighting their importance, technological advancements, challenges, and future prospects.

The Importance of Welding in Industry

Welding is a fundamental process in manufacturing, construction, and fabrication. It is essential for joining materials, particularly metals, to create strong, durable structures that are crucial in various sectors such as automotive, aerospace, construction, and shipbuilding. The need for high-quality welding techniques has driven the demand for efficient and innovative welding processes like TIG, MIG, and Stick welding.

Overview of Welding Techniques

- TIG Welding Known for its precision and control, TIG welding utilizes a non-consumable tungsten electrode and an inert gas shield. This method is widely used for welding thin materials and produces high-quality welds with excellent aesthetic finishes. It is ideal for stainless steel, aluminum, and other non-ferrous metals.

- MIG Welding MIG welding, or Gas Metal Arc Welding (GMAW), employs a continuous wire feed as the electrode and uses a shielding gas to protect the weld from contamination. It is favored for its speed and adaptability, making it suitable for various applications, including thick materials and different metal types. MIG welding is particularly popular in automotive manufacturing due to its efficiency.

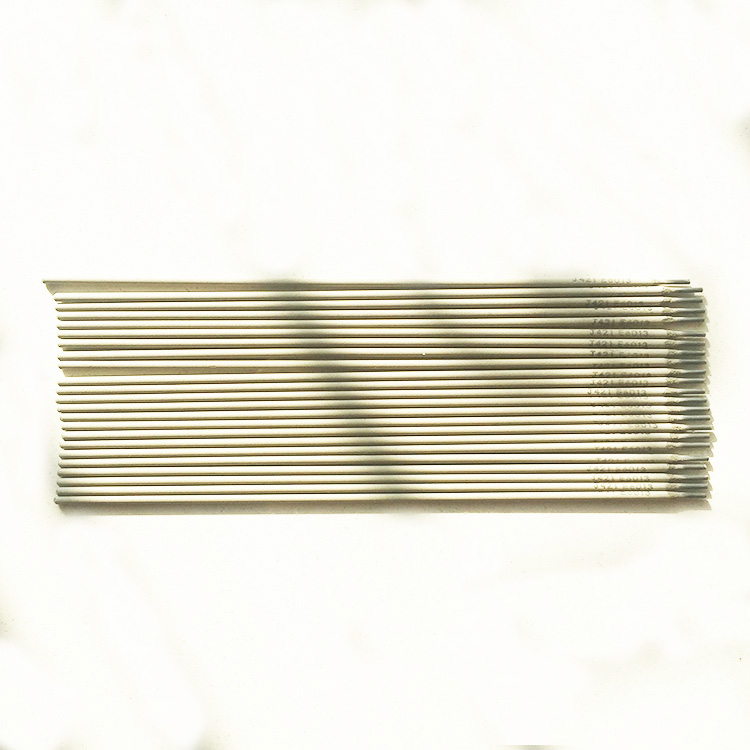

- Stick Welding Also known as Shielded Metal Arc Welding (SMAW), Stick welding is one of the oldest methods and is highly versatile. It uses a consumable electrode coated in a flux to create the weld. This method is particularly useful for outdoor work where wind may affect gas shielding. Stick welding is generally more accessible and less expensive compared to others, making it a popular choice for maintenance and repair applications.

china tig mig stick welding factories

Technological Advancements

China's welding factories have embraced modern technologies to enhance productivity and quality. Automation has become integral in many welding operations, with robotic welding systems becoming standard in large-scale manufacturing settings. These advancements allow for faster production rates, reduced human error, and improved safety standards. Additionally, the incorporation of digital technologies like IoT and artificial intelligence has enabled better tracking and monitoring of the welding process, contributing to improved efficiencies.

Challenges Faced by the Industry

Despite the growth and advancements, there are challenges that China's welding factories face. One major issue is the skilled labor shortage, as the industry requires trained professionals who can operate advanced welding machines and technologies. Additionally, competition has intensified, not only among domestic manufacturers but also with global players in the welding market.

Environmental regulations are another challenge, as factories must comply with stringent standards regarding emissions and waste management. Investing in cleaner technologies and sustainable practices is crucial for compliance and for maintaining a competitive edge.

Future Prospects

Looking ahead, the future of welding in China appears promising. With the continued growth in industries such as construction, automotive, and renewable energy, the demand for advanced welding techniques will remain strong. Furthermore, the emphasis on research and development will likely lead to innovations that enhance productivity, sustainability, and the quality of welding practices.

In conclusion, China's TIG, MIG, and Stick welding factories play a vital role in the nation's manufacturing landscape. Through continuous innovation and adaptation to industry changes, these factories are poised to meet the growing demands of various sectors while overcoming the challenges that lay ahead. As technology evolves and sustainability becomes increasingly important, the welding industry in China will undoubtedly continue to thrive on a global scale.

-

E71T-11 Flux Core Wire: Premium Gasless Welding SolutionNewsAug.28,2025

-

Premium Carbon Rods for Welding | Stable Arc & Precise GougingNewsAug.27,2025

-

Carbon Steel Welding Wire: Superior Strength & PrecisionNewsAug.26,2025

-

AWS E6013 Welding Electrodes: All-Position & Smooth Arc RodsNewsAug.25,2025

-

E312 Electrode: High Strength Welding Rod for Dissimilar MetalsNewsAug.24,2025

-

J506 Welding Rod: High-Strength, Crack-Resistant ElectrodeNewsAug.23,2025