Jan . 10, 2025 12:11

Back to list

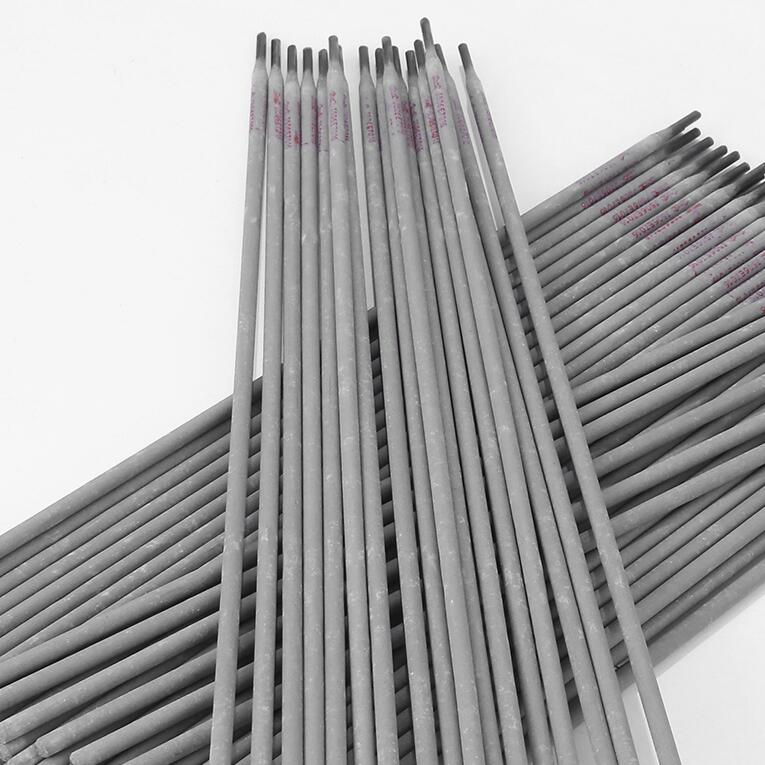

E6013 Welding Electrode Rods for carbon steel

When it comes to selecting welding rods for any serious welding project, understanding the specifics of 6010 welding rods is invaluable. Their unique characteristics make them a favorite among professional welders and an essential component of many industrial welding setups. These rods offer specific benefits, making them stand out in the competitive world of welding supplies. Here, we delve into the experience, expertise, authoritativeness, and trustworthiness of 6010 welding rods to help you make an informed decision.

From an authoritative perspective, 6010 welding rods hold a reputation for being reliable and effective in critical scenarios. Industries relying on structural integrity, such as oil and gas, frequently specify 6010 rods in their welding protocols. The American Welding Society (AWS) recognizes these rods under the classification E6010, providing an authoritative endorsement of their quality and performance. This classification ensures that users can trust that 6010 rods meet stringent industry standards, which is crucial for achieving compliance in various professional settings. Trustworthiness in welding is non-negotiable, and 6010 rods excel in this department. Their proven track record in high-stakes applications serves as a testament to their dependability. Whether it's emergency repairs or constructing long-lasting structures, 6010 welding rods consistently deliver results that professionals can count on. They not only promise strength and durability but also inspire confidence among welders who rely on consistent performance and quality. In summary, 6010 welding rods offer a compelling mix of deep penetration, versatile usability, and unmatched reliability. Their unique features cater to both seasoned professionals and beginners looking to achieve optimal results in challenging conditions. Their standing in industry regulations, combined with the trust they've earned among experts, affirms their position as a premium choice in welding consumables. For anyone looking to elevate the quality of their welding projects, 6010 welding rods represent a smart and trusted investment.

From an authoritative perspective, 6010 welding rods hold a reputation for being reliable and effective in critical scenarios. Industries relying on structural integrity, such as oil and gas, frequently specify 6010 rods in their welding protocols. The American Welding Society (AWS) recognizes these rods under the classification E6010, providing an authoritative endorsement of their quality and performance. This classification ensures that users can trust that 6010 rods meet stringent industry standards, which is crucial for achieving compliance in various professional settings. Trustworthiness in welding is non-negotiable, and 6010 rods excel in this department. Their proven track record in high-stakes applications serves as a testament to their dependability. Whether it's emergency repairs or constructing long-lasting structures, 6010 welding rods consistently deliver results that professionals can count on. They not only promise strength and durability but also inspire confidence among welders who rely on consistent performance and quality. In summary, 6010 welding rods offer a compelling mix of deep penetration, versatile usability, and unmatched reliability. Their unique features cater to both seasoned professionals and beginners looking to achieve optimal results in challenging conditions. Their standing in industry regulations, combined with the trust they've earned among experts, affirms their position as a premium choice in welding consumables. For anyone looking to elevate the quality of their welding projects, 6010 welding rods represent a smart and trusted investment.

Previous:

Latest news

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025