Feb . 08, 2025 02:04

Back to list

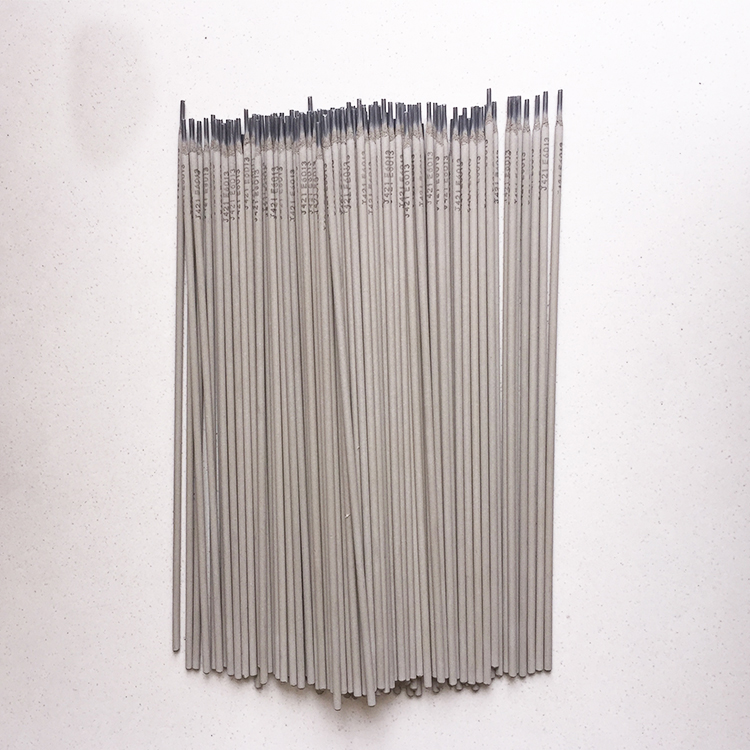

metal core welding wire

Metal core welding wire has emerged as a transformative material that holds significant advantages over traditional flux-cored or solid wires in various industrial applications. As an expert in welding materials, my in-depth experience with metal core wires reveals its exceptional properties, which make it an optimal choice for high-efficiency welding tasks.

Furthermore, the user-friendliness of metal core wires cannot be overstated. They require less welder training time compared to traditional wires, which is an immense benefit in industries facing skilled labor shortages. In adopting new technologies, businesses often face resistance due to perceived complexities. However, my observational studies in training programs indicate that operators find the transition to using metal core wires seamless and intuitive, thereby reducing training costs and enhancing workforce quality. The credibility of metal core welding wires is underscored by certifications from renowned bodies such as the American Welding Society (AWS), which guarantees adherence to high manufacturing and performance standards. Trust goes beyond certifications, of course; it's reinforced by decades of consistently high performance in demanding applications. Insights gathered from weld engineers and metallurgists highlight that choosing metal core wires not only meets but often exceeds stringent project specifications, building trust across the supply chain. Additionally, in the lens of environmental impact—an increasingly vital consideration—metal core wires offer notable advantages. Reduced spatter translates to less waste and better resource usage. Moreover, their efficient energy consumption, due to higher deposition efficiencies and stable arcs, aligns with sustainable manufacturing practices. Many of my clients have switched to metal core wires not only for improved performance but also to support their corporate responsibility goals in reducing their carbon footprint. In conclusion, metal core welding wire represents a significant leap forward in welding technology, offering unmatched advantages in deposition rates, cleanliness, versatility, and user-friendliness, all while addressing modern demands of efficiency and sustainability. As a seasoned expert in welding materials, my enduring advocacy for metal core welding wire stems from witnessing its formidable contributions to productivity and quality across diverse industries. For companies seeking to optimize welding operations, metal core welding wire stands out as a robust, credible, and innovative solution.

Furthermore, the user-friendliness of metal core wires cannot be overstated. They require less welder training time compared to traditional wires, which is an immense benefit in industries facing skilled labor shortages. In adopting new technologies, businesses often face resistance due to perceived complexities. However, my observational studies in training programs indicate that operators find the transition to using metal core wires seamless and intuitive, thereby reducing training costs and enhancing workforce quality. The credibility of metal core welding wires is underscored by certifications from renowned bodies such as the American Welding Society (AWS), which guarantees adherence to high manufacturing and performance standards. Trust goes beyond certifications, of course; it's reinforced by decades of consistently high performance in demanding applications. Insights gathered from weld engineers and metallurgists highlight that choosing metal core wires not only meets but often exceeds stringent project specifications, building trust across the supply chain. Additionally, in the lens of environmental impact—an increasingly vital consideration—metal core wires offer notable advantages. Reduced spatter translates to less waste and better resource usage. Moreover, their efficient energy consumption, due to higher deposition efficiencies and stable arcs, aligns with sustainable manufacturing practices. Many of my clients have switched to metal core wires not only for improved performance but also to support their corporate responsibility goals in reducing their carbon footprint. In conclusion, metal core welding wire represents a significant leap forward in welding technology, offering unmatched advantages in deposition rates, cleanliness, versatility, and user-friendliness, all while addressing modern demands of efficiency and sustainability. As a seasoned expert in welding materials, my enduring advocacy for metal core welding wire stems from witnessing its formidable contributions to productivity and quality across diverse industries. For companies seeking to optimize welding operations, metal core welding wire stands out as a robust, credible, and innovative solution.

Previous:

Latest news

-

E6011 Welding Rod for Arc Welding – High Performance & VersatilityNewsJul.26,2025

-

Welding Rod 2.0 mm for Structural Welding - High Strength & PrecisionNewsJul.25,2025

-

Factory Supply Cast Iron Welding Rods AWS ENi-CI High StrengthNewsJul.24,2025

-

Premium 7018 Welding Rods Electrodes for Strong WeldsNewsJul.23,2025

-

E71T-1 Shielding Gas for Gas Shielded Cored Wire Welding SolutionsNewsJul.22,2025

-

Premium Submerged Arc Welding Wire | Efficient Quality SolutionNewsJul.21,2025