mig wire 0.6mm manufacturers

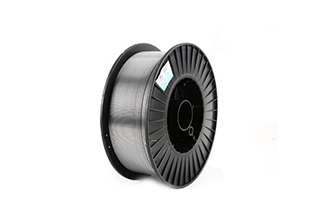

Understanding MIG Wire 0.6mm A Guide for Manufacturers

MIG (Metal Inert Gas) welding is a widely used welding process, celebrated for its versatility, efficiency, and the quality of welds it produces. Among various MIG welding wires available in the market, the 0.6mm MIG wire stands out for its unique advantages, especially in various manufacturing applications. This article explores the significance, benefits, and considerations of 0.6mm MIG wire, particularly in the context of manufacturers.

What is 0.6mm MIG Wire?

MIG wire comes in various diameters, with the 0.6mm variant being particularly useful for thin materials due to its fine diameter. This type of wire is typically used in conjunction with a MIG welding machine, feeding through a welding gun where it melts to form a weld pool. The diameter of the wire plays a critical role in determining the heat input and penetration, which are crucial factors in achieving strong, reliable welds.

Key Advantages of 0.6mm MIG Wire

1. Precision Welding The fine diameter of the 0.6mm wire allows for more control during the welding process. This is especially important when working with thinner sheets of metal, as it minimizes the risk of burn-through and warping.

2. Versatility Manufacturers often deal with a variety of materials and thicknesses. The 0.6mm MIG wire is versatile enough to handle different types of metals, including mild steel, stainless steel, and aluminum, making it a valuable addition to any workshop.

3. Reduced Spatter One of the common issues faced during welding is the generation of spatter, which requires additional cleanup. The 0.6mm wire, when paired with appropriate welding settings, tends to produce less spatter, leading to cleaner welds and easier post-weld processing.

4. Improved Travel Speed The smaller diameter allows for faster travel speeds, increasing productivity in manufacturing environments. Faster welding means more completed projects in a shorter amount of time, maximizing operational efficiency.

mig wire 0.6mm manufacturers

Considerations for Manufacturers

While the 0.6mm MIG wire offers numerous advantages, manufacturers need to consider several factors when integrating it into their operations.

1. Welding Machine Compatibility Not all MIG welding machines are compatible with all wire diameters. Manufacturers must ensure that their equipment can properly accommodate 0.6mm wire and set the appropriate voltage and feed speed.

2. Shielding Gas The choice of shielding gas is essential in MIG welding. For 0.6mm wire, a mixture of argon and carbon dioxide is commonly used to improve weld quality and reduce porosity. Manufacturers should analyze their welding environment to select the most suitable gas.

3. Material Thickness While the 0.6mm wire works well with thin materials, using it on thicker sections may require multiple passes or switching to a larger diameter wire for optimal results. This versatility in wire selection is crucial for manufacturing efficiency.

4. Welding Techniques Different welding techniques, such as short-circuiting, globular, and spray transfer, can affect the quality of the weld. Manufacturers should train their staff to select the appropriate technique based on the specific application and materials involved.

Conclusion

For manufacturers engaged in welding operations, 0.6mm MIG wire represents an excellent choice for achieving high-quality, precise welds on thin materials while minimizing spatter and improving travel speeds. By ensuring compatibility with welding equipment and understanding the relevant parameters involved in the welding process, manufacturers can maximize the benefits of using this wire in their operations.

In a competitive manufacturing landscape, an investment in the right tools and materials, such as 0.6mm MIG wire, can lead to significant improvements in productivity and quality. As the industry continues to evolve, staying informed about new technologies and materials will be key to maintaining a competitive edge and delivering superior products.

-

3.25mm Welding Electrodes High-Performance, Durable Wholesale FactoryNewsMay.19,2025

-

AWS A5.1 E6010 Welding Rods Durable All-Position ElectrodesNewsMay.19,2025

-

Wholesale E6013 Welding Electrodes Factories Durable & AffordableNewsMay.18,2025

-

SG2 TIG Welding Wire 2.4mm - High Durability & Precision Welding SolutionNewsMay.18,2025

-

High-Quality 025 Flux Cored Welding Wire Wholesale Factory & SupplierNewsMay.18,2025

-

Gasless Stainless Steel MIG Welding Wire High-Quality Flux-Core SolutionNewsMay.17,2025