sg2 welding wire

Exploring the World of SG2 Welding Wire Characteristics, Applications, and Benefits

Welding is an essential process in various industries, from construction and automotive manufacturing to shipbuilding and pipeline installation. One of the critical components in achieving high-quality welds is the choice of the right welding wire. Among the many types of welding wires available, SG2 welding wire stands out for its unique characteristics and versatile applications. This article delves into SG2 welding wire, discussing its properties, uses, and advantages.

Understanding SG2 Welding Wire

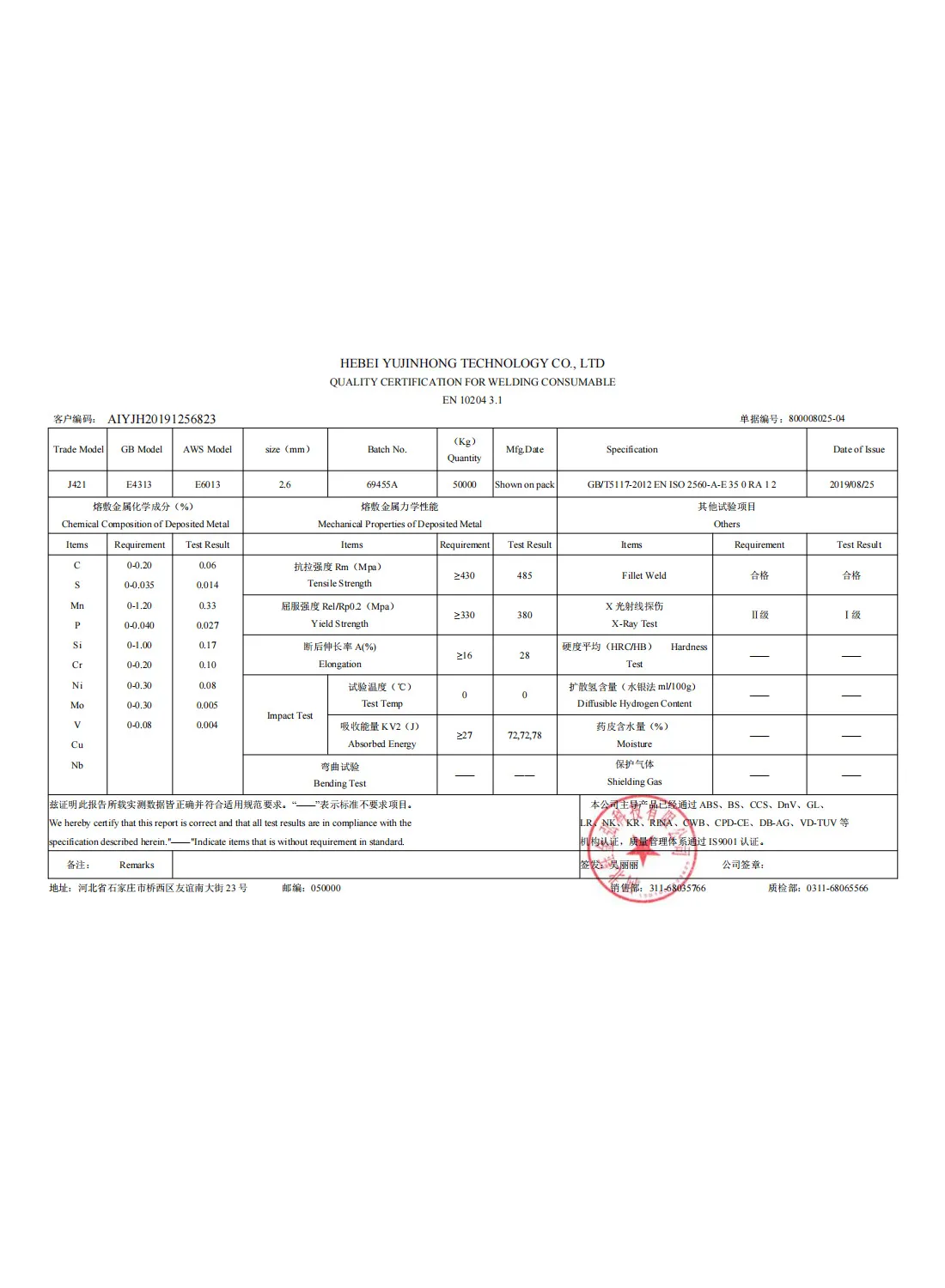

SG2 welding wire is a solid wire used primarily in gas metal arc welding (GMAW) processes. It is made from a combination of steel and alloying elements that provide strength, ductility, and resistance to different forms of stress. The distinctive feature of SG2 wire is its chemical composition, which typically includes elements such as carbon, manganese, and silicon. This composition imparts excellent weldability and mechanical properties to the wire, making it a preferred choice for many welding applications.

SG2 wire is categorized under the ER70S-6 classification, denoting its suitability for welding carbon steels. The ER prefix signifies that it is an electrode rod, while the 70 indicates the minimum yield strength of 70,000 psi (pounds per square inch). The S refers to solid, and the 6 indicates a specific composition that enhances its usability across various welding processes.

Key Characteristics

One of the primary attributes of SG2 welding wire is its exceptional arc stability. This characteristic is critical for achieving clean and precise welds, as it helps to minimize spatter and ensures better control during the welding process. Additionally, SG2 wire offers a good balance of deoxidizers, which reduce the risk of inclusions in the weld pool and enhance the overall quality of the welded joint.

Another notable feature of SG2 welding wire is its versatility. It can be used with different shielding gases, including carbon dioxide (CO2) and argon-CO2 mixtures. This adaptability allows welders to tailor their setups according to specific requirements, improving the efficiency and quality of their work.

sg2 welding wire

Applications of SG2 Welding Wire

SG2 welding wire finds extensive applications in various sectors. Its primary use is in the fabrication and repair of steel structures, including bridges, pipelines, and industrial equipment. The wire is also commonly employed in automotive manufacturing, particularly in the assembly of car bodies and frames. Its ability to produce strong, durable joints makes it ideal for high-stress applications, including the construction of machinery and heavy equipment.

Moreover, SG2 welding wire is suitable for both indoor and outdoor welding, providing flexibility for welders working in different environments. Whether it’s a workshop or a construction site, SG2 wire can deliver consistent quality, making it a reliable choice for professionals in the industry.

Benefits of Using SG2 Welding Wire

Welders opt for SG2 welding wire for several reasons, the foremost being its ease of use. The wire's excellent handling properties and compatibility with various welding machines make it accessible for both novice and experienced welders. Additionally, the cost-effectiveness of SG2 wire makes it an attractive option for businesses looking to maintain high standards while managing operational expenses.

Another significant benefit is the high-quality welds produced by SG2 wire. The wire’s ability to create strong, aesthetically pleasing welds with minimal cleanup saves time and improves overall productivity. Furthermore, the welds are less prone to defects such as cracks and porosity, which are critical factors in ensuring the longevity and safety of welded structures.

Conclusion

In conclusion, SG2 welding wire is an exceptional choice for anyone involved in welding applications. With its outstanding characteristics, versatility, and cost-effectiveness, it meets the demands of various industries while ensuring high-quality results. As technology evolves and the need for strong, reliable welds continues to grow, SG2 welding wire will undoubtedly remain a vital tool in the welder's arsenal, contributing to the creation of robust structures that stand the test of time. Whether for industrial manufacturing or repair work, SG2 welding wire exemplifies excellence in the world of welding materials.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025