Top Manufacturers of Solid Stainless Steel Welding Wire for Quality Performance

The Importance of Choosing the Right Stainless Steel Welding Wire Solid Manufacturer

In the realm of metal fabrication and welding, the choice of materials significantly influences the quality and durability of the final product. Among these materials, stainless steel is revered for its exceptional corrosion resistance, strength, and aesthetic appeal. However, the selection of stainless steel welding wire solid is critical, as it serves as the backbone of the welding process. Therefore, identifying a trustworthy stainless steel welding wire solid manufacturer is essential for welders and fabricators alike.

Understanding Stainless Steel Welding Wire Solid

Stainless steel welding wire is primarily used in various welding processes such as MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas). This wire is designed to produce a strong and lasting bond between pieces of stainless steel, ensuring that the weld is both functional and visually appealing. Solid welding wire, in particular, refers to a type of wire that is without a core of any additional materials, making it suitable for high-strength applications where robustness is essential.

The advantages of using stainless steel welding wire include its excellent corrosion resistance, high tensile strength, and compatibility with various stainless steel grades. It can be used in diverse applications, including construction, automotive, food processing, and chemical manufacturing.

Factors to Consider When Choosing a Manufacturer

When it comes to selecting a stainless steel welding wire solid manufacturer, several factors should be taken into account to ensure that you receive high-quality products that meet your specific needs.

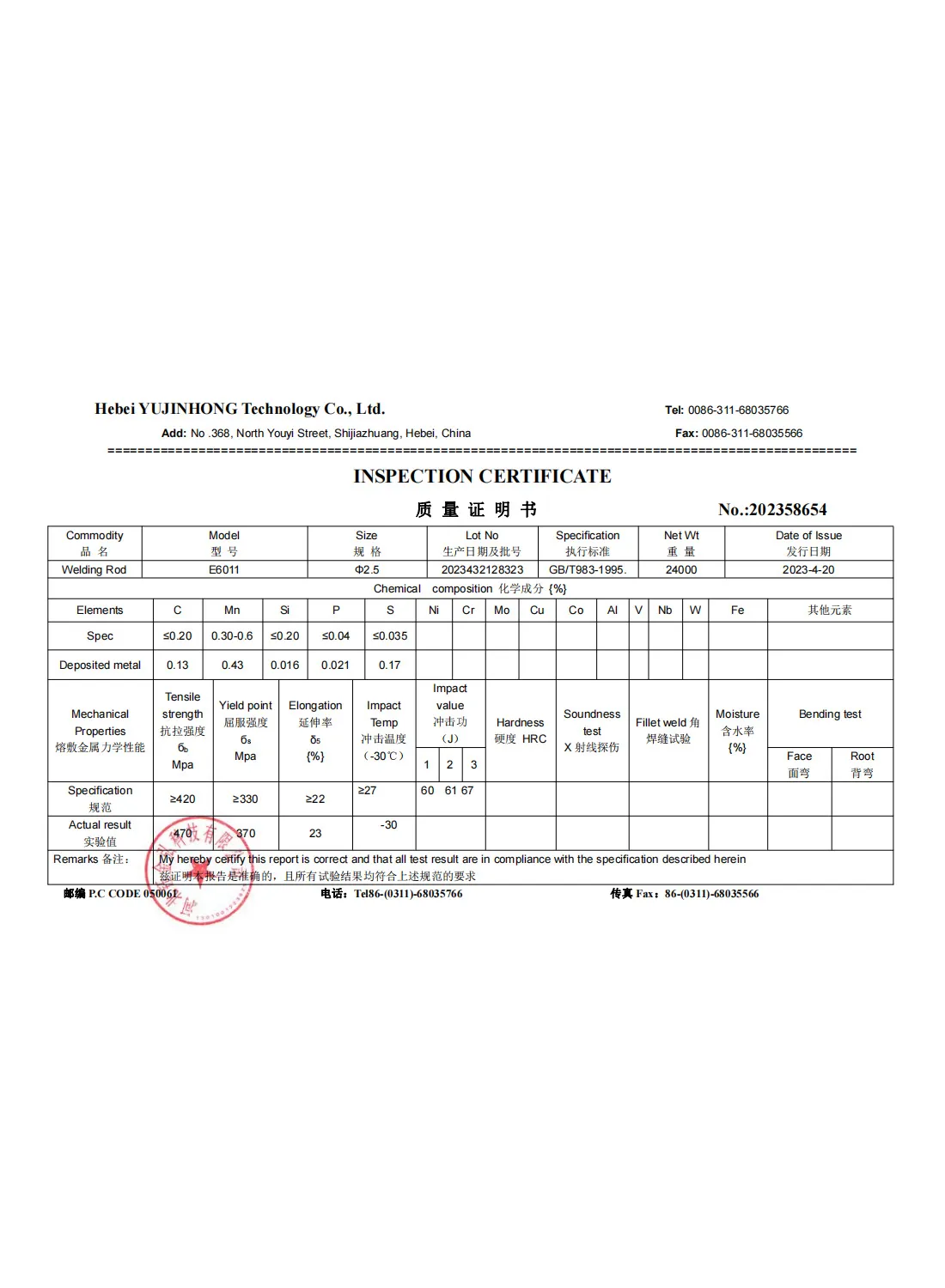

1. Quality Assurance The first and foremost consideration is the quality of the welding wire produced. Look for manufacturers that adhere to international quality standards such as ISO 9001. Reliable manufacturers will provide certifications and test reports that verify the quality and performance of their welding wire.

stainless steel welding wire solid manufacturer

2. Material Composition Different grades of stainless steel offer varying properties. A reputable manufacturer should provide clarity on the chemical composition of their products, enabling you to choose the right wire for your specific application. This information is crucial for ensuring compatibility and achieving optimal weld quality.

3. Variety of Products A good manufacturer will present a range of stainless steel welding wires in different diameters and grades. This variety allows fabricators and welders to choose products that best fit their projects, enhancing their flexibility in material selection.

4. Technical Support The complexity of welding processes often requires guidance and support. A manufacturer that offers technical assistance can be invaluable, providing insights into best practices and helping troubleshoot any issues that arise during the welding process.

5. Reputation and Experience Investigating the manufacturer’s reputation in the industry is crucial. Established manufacturers with years of experience often have a proven track record of delivering quality products. Customer reviews, testimonials, and case studies can provide insight into their service and product reliability.

6. Pricing and Availability While cost should not be the only deciding factor, it plays a significant role in project budgeting. Compare prices among different manufacturers, but also ensure that the lower cost does not compromise quality. Additionally, consider the availability and lead times for orders to ensure that your project timelines are met.

Conclusion

Selecting the right stainless steel welding wire solid manufacturer is a crucial step for anyone involved in welding and metal fabrication. The quality of the welding wire directly impacts the performance of the weld, influencing the safety, durability, and strength of the final product. By considering factors such as quality assurance, material composition, product variety, technical support, reputation, and pricing, welders and fabricators can make informed decisions that lead to successful outcomes. Ultimately, the right manufacturer can enhance productivity, improve weld quality, and ensure that projects meet the stringent demands of modern applications. As the industry evolves, staying informed and selecting the right partners becomes integral to success in welding and fabrication.

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025

-

Arc Welding Electrodes AWS E7024 – High Deposition, Smooth FinishNewsJul.30,2025