Leading Manufacturer of High-Quality Stainless Steel Welding Wire Solutions for Your Needs

The Role of Stainless Welding Wire Manufacturers in Modern Industry

In the realm of industrial fabrication and construction, stainless welding wire is an essential material that plays a vital role in ensuring the durability and integrity of welded structures. Stainless steel, known for its resistance to corrosion and ability to withstand extreme temperatures, is commonly used in various sectors, including automotive, aerospace, food processing, and construction. This article explores the importance of stainless welding wire manufacturers and the impact they have on modern industry.

Understanding Stainless Welding Wire

Stainless welding wire is a specialized filler material used during the welding process to join stainless steel components. It facilitates the creation of strong, reliable welds that can endure the punishing conditions found in many industrial applications. Typically made from high-quality stainless steel alloys, these wires are designed to provide excellent corrosion resistance, strength, and ductility, making them a preferred choice for projects where long-term performance is critical.

The Manufacturing Process

The manufacturing of stainless welding wire involves intricate processes that ensure the final product meets stringent quality standards. Raw materials, primarily stainless steel scrap and scrap metal, undergo careful selection and preparation. The production process typically includes

1. Melting and Alloying The raw materials are melted in a controlled environment, allowing for the precise combination of alloys needed for specific welding applications.

2. Wire Drawing After melting, the molten metal is cast into billets and cooled. These billets are then further processed through wire drawing, where they are pulled through a series of dies to achieve the desired diameter.

4. Coating and Packaging Depending on the intended use, the welding wire may receive various coatings to prevent oxidation and improve performance during welding. Finally, the wire is spooled, labeled, and packaged for distribution.

stainless welding wire manufacturer

Importance of Quality and Standards

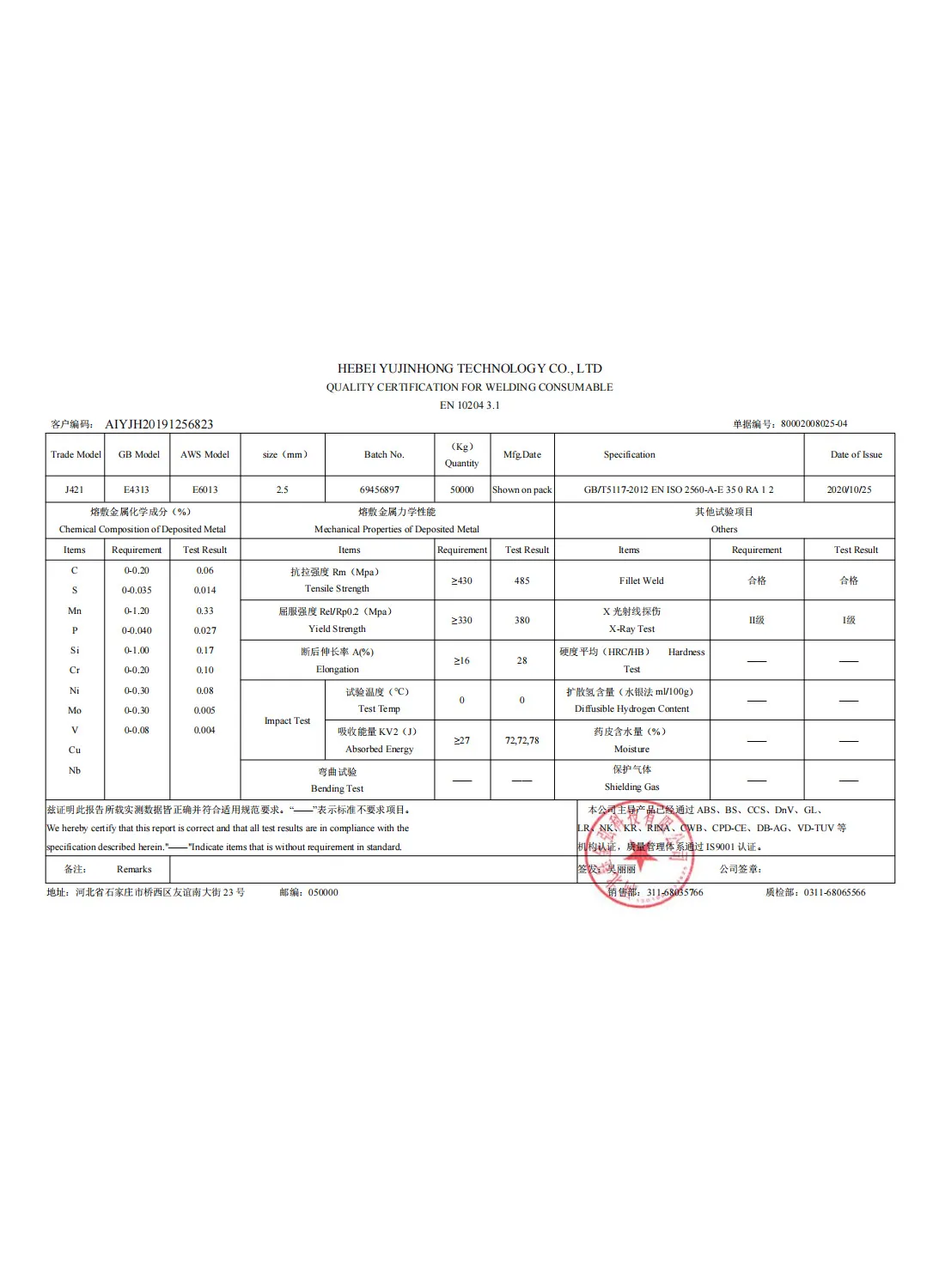

Given the critical role stainless welding wire plays in structural integrity, quality standards are paramount. Reputable manufacturers adhere to international standards such as ISO 9001, AWS (American Welding Society), and others relevant to specific industries. These standards not only ensure that the welding wire performs optimally in various conditions but also guarantee safety and reliability in all applications.

Quality control processes include rigorous testing, such as tensile testing, chemical composition analysis, and corrosion resistance assessments. Manufacturers invest significantly in technology and skilled personnel to maintain the highest quality throughout the production process.

Environmental Considerations

With the increasing focus on sustainability, many stainless welding wire manufacturers are implementing environmentally friendly practices. This includes recycling scrap materials, minimizing waste during production, and adhering to regulations regarding emissions and resource use. By adopting sustainable practices, manufacturers contribute to the overall goal of reducing the environmental impact of the welding industry.

The Future of Stainless Welding Wire Manufacturing

As industries continue to evolve, so too does the demand for advanced materials and technologies. Stainless welding wire manufacturers are tasked with developing innovative products that meet changing industry needs. This includes exploring new alloy compositions for enhanced performance, improving the manufacturing process for efficiency, and adopting automation and digital technologies for better quality control.

Emerging applications, such as additive manufacturing and 3D printing, also present new opportunities for stainless welding wire manufacturers. As these technologies gain traction, the ability to produce specialized wire tailored for specific applications will become increasingly important.

Conclusion

Stainless welding wire manufacturers serve as the backbone of many industrial sectors, providing essential materials that ensure the strength, durability, and safety of welded structures. By adhering to stringent quality standards, embracing sustainable practices, and innovating for the future, these manufacturers will continue to play a vital role in fostering growth and innovation across various industries. As we look ahead, their contributions will undoubtedly enhance the capabilities of modern engineering and construction, paving the way for a more resilient and advanced industrial landscape.

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025