Stick Arc Welding Production Facility for High-Quality Industrial Applications and Custom Solutions

The Rise of Stick Arc Welding Factories A Cornerstone of Modern Manufacturing

In the heart of modern manufacturing, stick arc welding has emerged as a pivotal technique that underpins various industries, from construction to automotive. Stick arc welding, also known as Shielded Metal Arc Welding (SMAW), uses a consumable electrode coated in flux to produce the weld. This process not only ensures strong and durable welds but also provides manufacturers with flexibility and efficiency that is crucial in today's competitive marketplace. The proliferation of stick arc welding factories is a testament to its importance and versatility.

One of the standout features of stick arc welding is its adaptability to different environments. Unlike other welding techniques that may require sophisticated equipment and specific conditions, stick arc welding can be executed in various settings, including outdoor and remote locations. This capability is vital for industries such as construction, where welders often work in challenging conditions. As a result, stick arc welding factories have become commonplace, meeting the demand for robust and reliable welding solutions.

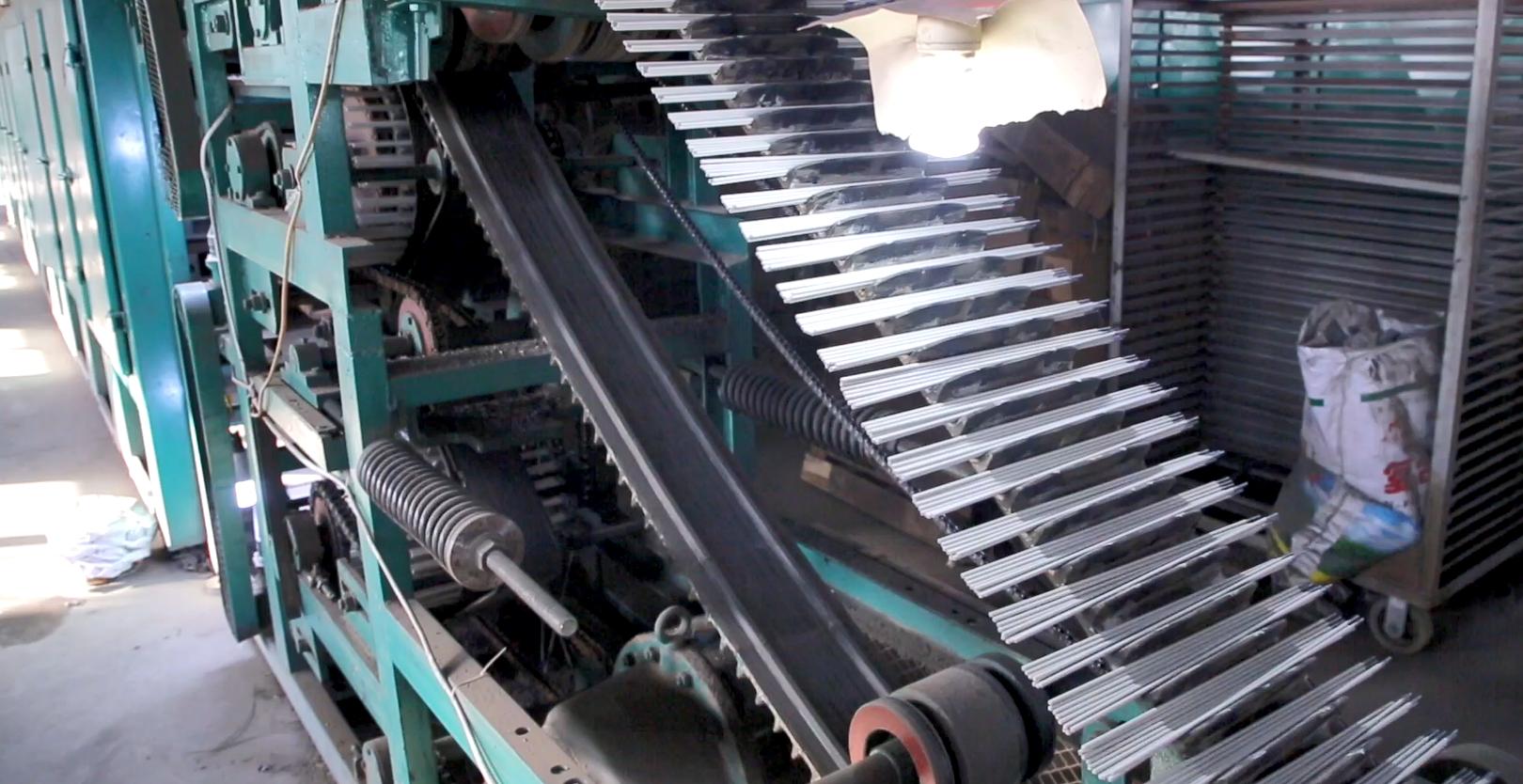

The production process within stick arc welding factories is streamlined and efficient. These factories are equipped with advanced technology that enhances productivity while ensuring high-quality outputs. Automated systems are increasingly integrated into the stick welding process, enabling factories to maintain consistent welding standards while reducing human error. For instance, the use of robotics coupled with skilled operators allows for meticulous control over the welding parameters, ensuring that every joint is of optimal strength and quality.

Furthermore, the economic advantages of stick arc welding contribute to its popularity among manufacturers. The materials used in stick welding are relatively inexpensive, and the process itself is less energy-intensive compared to other welding methods. This cost-effectiveness makes stick arc welding factories an appealing choice for companies looking to reduce operational expenses without sacrificing quality. Additionally, the simple equipment required for stick welding means that initial investment costs are lower, allowing for wider access to this welding technique for small to medium-sized enterprises.

stick arc welding factory

Another factor driving the growth of stick arc welding factories is the skilled labor required to operate and manage welding tasks. While the manual aspect of stick welding means that skilled welders are indispensable, this has created a demand for vocational training programs. Many manufacturers have recognized the importance of investing in their workforce, leading to partnerships with educational institutions to develop training programs tailored to the needs of the industry. This focus on skills development not only benefits the individual welders but also strengthens the overall workforce in the manufacturing sector.

The sustainability aspect of stick arc welding should not be overlooked. As industries move towards more eco-friendly practices, stick arc welding has demonstrated its capability to adapt. Many factories are implementing sustainable practices, such as recycling welding materials and reducing waste. The development of new, environmentally friendly flux coatings and electrodes further underscores the industry's commitment to sustainability.

Moreover, stick arc welding plays a crucial role in infrastructure development, particularly in developing economies. As nations invest in their infrastructure, the demand for reliable and efficient welding techniques surges. Stick arc welding factories provide those nations with an opportunity to bolster their manufacturing capabilities, enabling them to compete on a global scale.

In conclusion, stick arc welding factories represent a significant advancement in the manufacturing process, characterized by adaptability, efficiency, and cost-effectiveness. Their role in developing industries, paired with a commitment to sustainability and workforce training, ensures that stick arc welding remains integral to modern manufacturing. As technology evolves and new innovations emerge, the future of stick arc welding appears bright, promising continued relevance and growth in the ever-changing landscape of industry. This fusion of tradition with innovation positions stick arc welding as not only a method of joining metal but as a critical component of contemporary industrial practices, shaping the future of manufacturing around the globe.

-

Gasless Stainless Steel MIG Welding Wire High-Quality Flux-Core SolutionNewsMay.17,2025

-

E6011 Welding Rod Meaning High Penetration & Versatile UseNewsMay.17,2025

-

High-Quality CS to SS Welding Electrodes 7016 Durable & Corrosion-ResistantNewsMay.16,2025

-

045 Flux Core Welding Wire High-Strength, Durable MIG Welding SolutionNewsMay.16,2025

-

Low Hydrogen Electrodes Types, Benefits & Durable Welding SolutionsNewsMay.15,2025

-

High-Durability 1.2mm Flux Cored Welding Wire Factory Direct SupplierNewsMay.15,2025