stick welding rod manufacturers

The Importance of Stick Welding Rod Manufacturers in the Welding Industry

Stick welding, also known as Shielded Metal Arc Welding (SMAW), is one of the most commonly used welding processes, particularly in construction, repair, and maintenance applications. Central to this process are the welding rods, which play an essential role in ensuring the quality and strength of the welds produced. Stick welding rod manufacturers are crucial players in the welding industry, providing the necessary materials that help achieve desirable welding outcomes.

Understanding Stick Welding Rods

Welding rods used in stick welding are coated electrodes that are designed to provide a flow of current and a filler material to join metal pieces together. The coating on these rods, typically made from a combination of flux and other materials, serves several purposes it protects the molten weld pool from contamination, stabilizes the arc, and facilitates the removal of slag after welding. The choice of welding rod is vital, as various rods are engineered for different applications, materials, and welding positions.

The Role of Manufacturers

Stick welding rod manufacturers are responsible for the production of these critical components. They must ensure that their products meet stringent industry standards and specifications. This involves selecting the right raw materials, employing advanced production techniques, and adhering to quality control measures throughout the manufacturing process. High-quality manufacturers invest in research and development to innovate and improve their products continually, ensuring they meet the evolving needs of welders and industries.

Quality Assurance and Standards

One of the primary concerns for welding professionals is the reliability of the welding rods they use. Manufacturers must adhere to international standards such as those set by the American Welding Society (AWS) and the International Organization for Standardization (ISO). These standards dictate the mechanical properties, chemical composition, and usability of welding rods, ensuring that they perform effectively in various applications.

stick welding rod manufacturers

Quality assurance processes in stick welding rod manufacturing often involve rigorous testing. This includes evaluating the rods for tensile strength, ductility, and the ability to produce clean and strong welds. Manufacturers may also conduct trials to test the rods' performance in real-world conditions, providing valuable feedback that can lead to further improvements.

Market Variety and Specialization

The market for stick welding rods is diverse, encompassing a wide range of products tailored for specific applications. For instance, manufacturers produce rods designed for different base metals, including mild steel, stainless steel, and cast iron. They also create specialty rods for unique environments, such as high-temperature or corrosive conditions.

Additionally, some manufacturers specialize in producing rods for specific industries, such as shipbuilding, automotive, or construction. This specialization allows manufacturers to tailor their products to meet the precise requirements of their clients, thereby enhancing the overall effectiveness of the welding process.

Sustainability and Innovation

In today’s environmentally conscious market, many stick welding rod manufacturers are focusing on sustainable practices. This includes using eco-friendly materials, optimizing production processes to reduce waste, and implementing recycling programs for steel and other materials. Innovation in manufacturing techniques and product design also contributes to more efficient and sustainable welding processes.

Conclusion

Manufacturers of stick welding rods play an indispensable role in the welding industry, providing essential materials that ensure the quality and reliability of welds across various applications. As technology evolves and industries demand higher performance standards, the importance of these manufacturers continues to grow. By adhering to stringent quality standards, focusing on innovation, and meeting the diverse needs of the market, stick welding rod manufacturers contribute significantly to the success and safety of welding projects worldwide.

-

E6011 Welding Rod for Arc Welding – High Performance & VersatilityNewsJul.26,2025

-

Welding Rod 2.0 mm for Structural Welding - High Strength & PrecisionNewsJul.25,2025

-

Factory Supply Cast Iron Welding Rods AWS ENi-CI High StrengthNewsJul.24,2025

-

Premium 7018 Welding Rods Electrodes for Strong WeldsNewsJul.23,2025

-

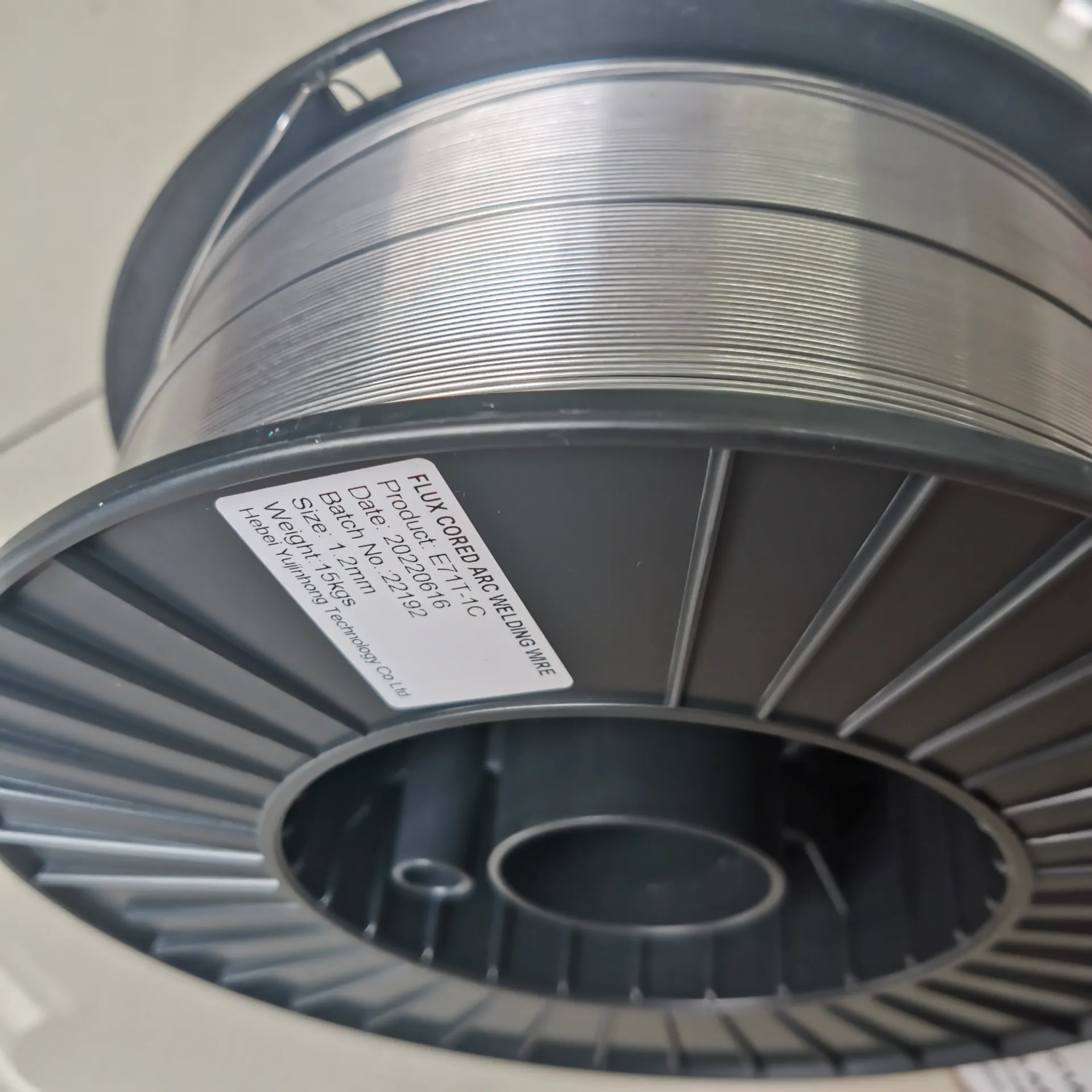

E71T-1 Shielding Gas for Gas Shielded Cored Wire Welding SolutionsNewsJul.22,2025

-

Premium Submerged Arc Welding Wire | Efficient Quality SolutionNewsJul.21,2025