2.4mm TIG Welding Wire Rod Supplier for High-Quality Metal Fabrication Applications

Understanding TIG Welding Wire Rods A Focus on 2.4mm Manufacturers

Tungsten Inert Gas (TIG) welding is a widely recognized and highly regarded welding process due to its precision and ability to create high-quality welds. Central to this process is the use of specialized welding wires, particularly in the diameter of 2.4mm, which is commonly utilized in various welding applications. This article delves into the significance of TIG welding wire rods, the specifications of 2.4mm wire, and the importance of selecting the right manufacturer.

What is TIG Welding?

TIG welding employs a non-consumable tungsten electrode to produce the weld. This method provides excellent control over the welding process, which allows for high-quality finishes and the ability to weld thin materials with precision. The inert gas (usually argon) shields the weld puddle from contamination, ensuring that the weld is clean and free from defects. This makes TIG welding ideal for applications in aerospace, automotive, and artistic metalworking.

The Importance of Wire Diameter

The diameter of the welding wire plays a crucial role in the quality and efficiency of the welding process. A 2.4mm wire rod is a popular choice among welders, as it strikes a balance between versatility and usability. This diameter is suitable for both thin and moderately thick materials, allowing welders to tackle a variety of jobs while maintaining control over the heat input and penetration.

Properties of 2.4mm TIG Welding Wire Rods

When selecting a 2.4mm TIG welding wire rod, several factors should be considered

1. Material Composition The wire’s material composition significantly impacts performance. Common materials include stainless steel, aluminum, and nickel alloys. Manufacturers typically offer a range of welding wires tailored to specific applications, ensuring optimal compatibility with the base materials.

2. Quality Standards Quality is paramount in welding. Reputable manufacturers adhere to international standards, such as ISO and AWS, to ensure their products meet industry requirements. Look for certificates and quality assurances that can validate a manufacturer’s claims.

tig welding wire rod 2.4mm manufacturer

3. Cleanliness and Preparation The cleanliness of the wire is essential in TIG welding. Contamination on the wire can lead to weld defects. A good manufacturer will ensure that their wire rods are properly cleaned and packaged to maintain their quality during transportation.

4. Performance Characteristics Different welding applications require different characteristics from the wire rod. Factors such as melting point, flexibility, and feedability all contribute to its performance. Manufacturers may provide detailed specifications that can help a welder choose the right rod for their specific needs.

Choosing the Right Manufacturer

Selecting a reliable manufacturer is crucial for achieving consistent results in TIG welding. Here are some tips to ensure you choose the right supplier

- Reputation and Experience Look for manufacturers with a solid reputation and extensive experience in producing welding rods. Industry reviews and testimonials can provide insights into their reliability and product quality.

- Product Range A manufacturer that offers a diverse range of welding wires and materials can cater to broader applications and specifications, providing flexibility for your welding projects.

- Customer Support Effective customer support is essential. A good manufacturer will provide technical support, helping you choose the right products and troubleshoot any issues that may arise during the welding process.

- Sustainability Practices With the growing emphasis on sustainability, consider manufacturers who employ environmentally friendly practices in their production processes.

Conclusion

TIG welding wire rods, particularly the 2.4mm diameter, are essential tools for achieving high-quality welds across various industries. Understanding the properties and specifications of these wires, as well as the importance of selecting a reputable manufacturer, is vital for any welding professional. By making informed choices, welders can enhance their work quality and efficiency, ensuring that every weld is both precise and durable. As the demand for high-quality welding continues to rise, investing in top-notch materials and manufacturers will always pay dividends in the long run.

-

Premium AC Stainless Steel Welding Rods - Durable & Corrosion-ResistantNewsAug.05,2025

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

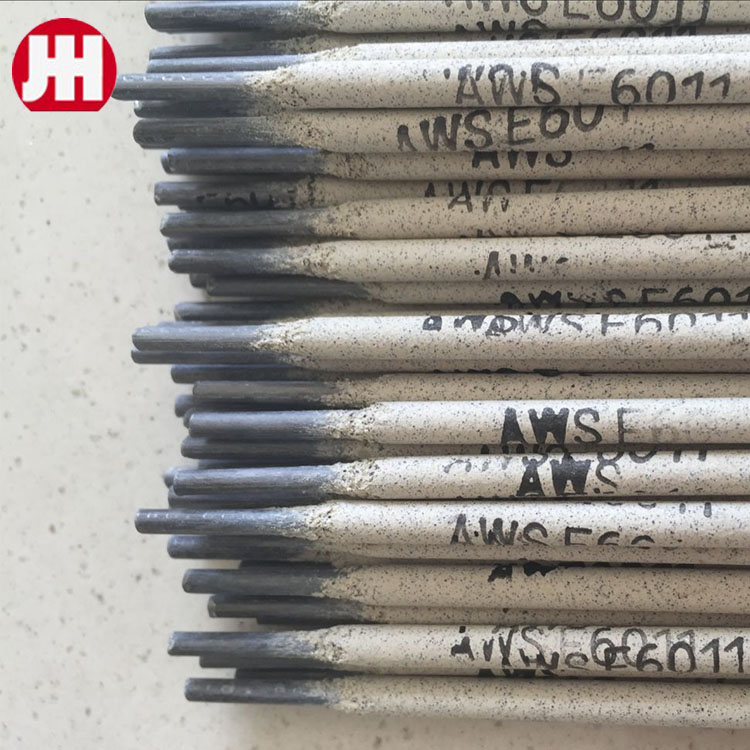

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025