welding electrode rod suppliers

Exploring Welding Electrode Rod Suppliers A Comprehensive Guide

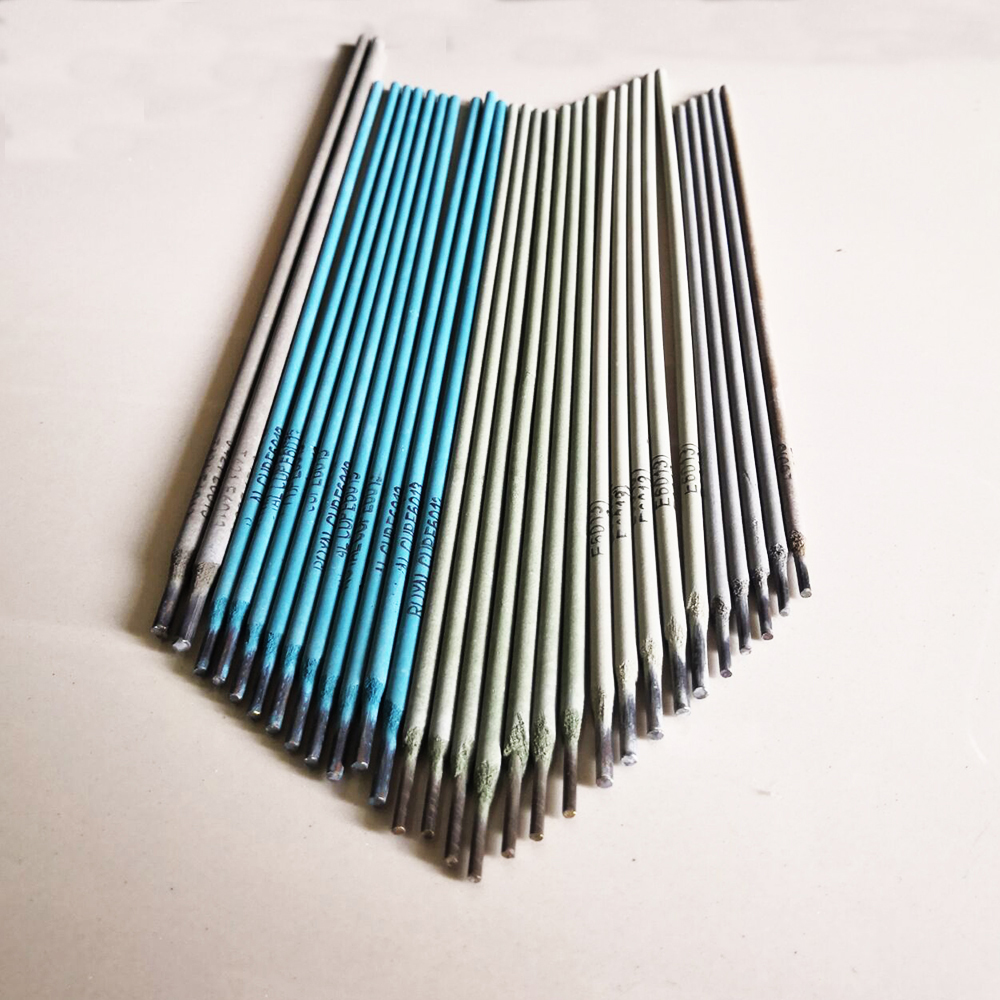

When it comes to welding, selecting the right materials is crucial for ensuring successful and durable outcomes. One of the key components in the welding process is the welding electrode rod. As a vital element in arc welding, the choice of electrode can significantly influence the quality of the weld. This article provides an overview of welding electrode rod suppliers, the factors to consider when choosing a supplier, and the importance of quality in welding operations.

Understanding Welding Electrodes

Welding electrodes are categorized into different types, each suited for specific applications and materials. Common types include covered electrodes, solid wire electrodes, and cored electrodes. The appropriate selection hinges on factors such as the material being welded, the welding position, and the specific welding technique being employed. Different suppliers may specialize in certain types of electrodes, making it essential to understand your needs before sourcing products.

Importance of Supplier Selection

Choosing a reliable welding electrode rod supplier is fundamental to the success of your welding projects. A reputable supplier not only provides high-quality products but also offers valuable expertise and support. Here are some key considerations when selecting a supplier

1. Quality Assurance Look for suppliers that adhere to industry standards and regulations. Certifications such as ISO 9001 indicate a commitment to quality management. Quality electrodes ensure better performance and longevity in welding applications.

2. Product Range A good supplier should offer a wide variety of electrode types and sizes. This range allows for flexibility to meet different project requirements, from heavy industrial applications to delicate fabrication tasks.

welding electrode rod suppliers

3. Technical Support Suppliers that provide technical support can help you choose the right electrodes for your specific welding tasks. This may include guidance on the best techniques, settings, and compatibility with equipment.

4. Pricing and Terms While quality is paramount, pricing will also influence your selection. Compare quotes from different suppliers while considering the overall value rather than just the price. Look for suppliers that offer bulk discounts or flexible payment terms for businesses.

5. Delivery and Service Reliability in delivery can significantly affect project timelines. Assess the supplier’s logistics and customer service. Having a local supplier can also reduce shipping costs and lead times.

The Role of Innovation

The welding industry is continually evolving, with advancements in technology and materials. Established suppliers often invest in research and development to produce innovative welding electrodes that improve efficiency and performance. These advancements can include new coatings for better arc stability, enhanced corrosion resistance, and electrodes designed for specific alloy types.

Conclusion

In conclusion, the choice of welding electrode rod suppliers plays a critical role in the success of welding operations. By considering factors such as quality, product range, technical support, pricing, and delivery, you can make an informed decision that will positively impact your projects. As the welding industry continues to advance, partnering with a supplier that values innovation and reliability will ensure that you are equipped with the best tools to achieve high-quality welds. Whether you are a large-scale manufacturer or a small workshop, investing time in selecting the right supplier will yield long-term benefits and contribute to the overall success of your welding endeavors.

-

AWS E6013 Welding Electrodes: All-Position & Smooth Arc RodsNewsAug.25,2025

-

E312 Electrode: High Strength Welding Rod for Dissimilar MetalsNewsAug.24,2025

-

J506 Welding Rod: High-Strength, Crack-Resistant ElectrodeNewsAug.23,2025

-

E71T-1 Shielding Gas for Superior Welding Quality & EfficiencyNewsAug.22,2025

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025