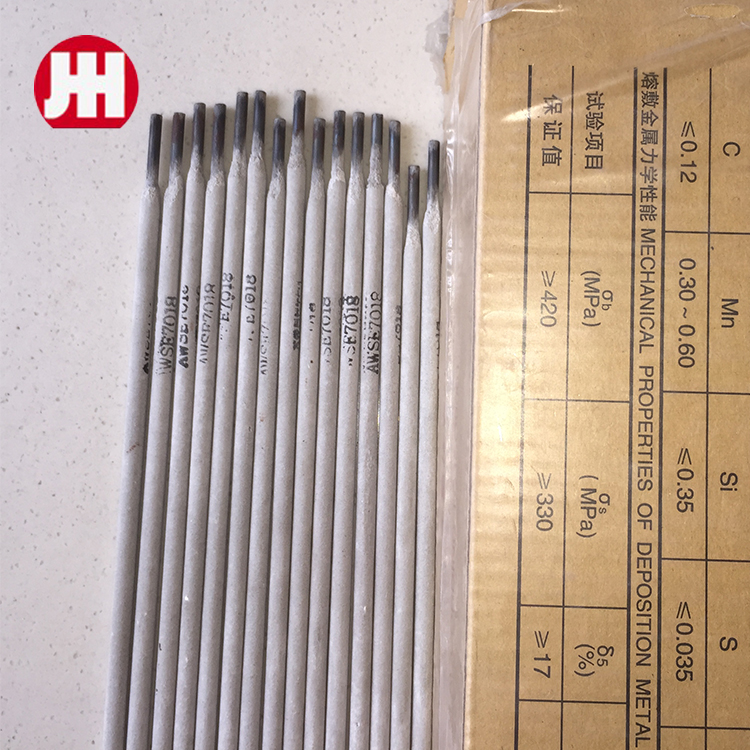

Supplier of 2.5mm 7018 Welding Electrodes for Wholesale Needs

The Importance of High-Quality Welding Electrodes A Focus on 2.5mm 7018

Welding is an essential process across various industries, from construction and automotive to manufacturing and shipbuilding. It requires precision, skill, and the right materials to ensure a sturdy and durable connection between metals. Among these materials, welding electrodes hold a notable place, especially 2.5mm 7018 electrodes. As industries search for reliable suppliers of wholesale welding electrodes, understanding the significance of these components becomes imperative.

What are 7018 Welding Electrodes?

7018 electrodes are low-hydrogen welding rods that are widely used in the shielded metal arc welding (SMAW) process. They are made of a specific alloy steel and are known for their high strength and excellent ductility. The 70 in 7018 signifies a minimum tensile strength of 70,000 psi, while the 18 indicates that these electrodes contain 0.18% iron powder, enhancing their ability to produce a smooth and stable arc. Welders prefer this type of electrode for their superior performance in critical applications, especially in the fabrication of structures that require high integrity and reliability.

The Versatility of 2.5mm Electrodes

The 2.5mm diameter of these electrodes makes them versatile for various welding applications. They can be employed in welding thin to medium-thickness materials, enabling welders to work on a range of projects from light fabrication tasks to heavy machinery assembly. The small size allows for better control and a finer bead, which is crucial when aesthetics and structural integrity are paramount. Moreover, 2.5mm electrodes are well-suited for welding positions, including flat, horizontal, vertical, and overhead, giving welders the flexibility they need to tackle diverse projects.

Why Choose Wholesale Suppliers?

When looking for welding electrodes, sourcing from wholesale suppliers can offer several advantages. One of the most significant benefits is cost-effectiveness. By purchasing in bulk, businesses can save on per-unit costs, which is crucial for large-scale operations. Additionally, wholesale suppliers often provide a broader range of products, ensuring that welders can find the exact specifications they need for their projects.

Quality is another major consideration. Wholesale suppliers usually maintain higher standards when it comes to the production and storage of their welding electrodes. This ensures that the electrodes are consistent in quality, performance, and reliability—factors that directly impact the outcome of welding projects. Opting for a reputable supplier with a focus on 2.5mm 7018 electrodes means investing in materials that can withstand rigorous conditions and deliver the expected results.

wholesale 2.5mm welding electrodes 7018 supplier

Factors to Consider When Choosing a Supplier

When selecting a wholesale supplier for 2.5mm 7018 electrodes, several factors should be taken into account

1. Reputation Research suppliers online, read reviews, and seek recommendations from industry peers to find a trusted source.

2. Certifications Ensure that the supplier follows quality standards and possesses necessary certifications, which can be a testament to their credibility.

3. Product Range A good supplier should offer various options, including different brands and specifications, to cater to specific welding needs.

4. Customer Service Assess the supplier's customer service capabilities. A supplier who can provide technical support and efficient communication is a valuable partner.

5. Pricing and Shipping Compare prices and look for suppliers who offer competitive pricing and favorable shipping options.

Conclusion

The choice of welding electrodes plays a critical role in the outcome of welding projects. 2.5mm 7018 welding electrodes stand out for their reliability, strength, and versatility, making them a preferred choice among professionals in the field. Opting for wholesale suppliers not only enhances cost-efficiency but also ensures access to high-quality materials necessary for achieving superior welding results. With careful consideration, businesses can establish long-term relationships with suppliers, facilitating seamless operations and successful project completions. Investing in quality welding materials reflects a commitment to excellence in every weld made.

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025