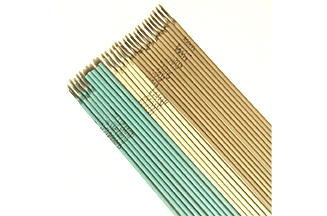

wholesale cellulose welding rod e6010 factory

Wholesale Cellulose Welding Rod E6010 Factory A Comprehensive Overview

In the ever-evolving landscape of industrial manufacturing, welding is a fundamental process that forms the backbone of countless structures and components across various sectors. Among the myriad of welding materials available in the market, cellulose welding rods, specifically E6010, have gained significant recognition due to their unique properties and applications. This article delves into the importance of E6010 cellulose welding rods and the role of factories that specialize in their wholesale production.

Understanding E6010 Cellulose Welding Rods

E6010 welding rods are specifically designed for use in stick or arc welding, primarily for welding mild steel. These electrodes are coated with cellulose that burns off during welding, allowing for an exceptional penetration into the base metal. This unique characteristic makes E6010 especially suitable for applications requiring deep welds, such as construction and repair work in the farming, shipbuilding, and heavy machinery industries.

The designation E6010 indicates several vital features of the rod. The E stands for electrode, while 60 signifies the minimum tensile strength of 60,000 psi. The 1 indicates that the rod can be used in any position, providing versatility for welders. These rods excel particularly in vertical and overhead positions, making them indispensable for many welding projects.

The Advantages of E6010 Rods

One of the primary advantages of cellulose welding rods like E6010 is their ability to produce strong and reliable welds. The high tensile strength ensures that the joints formed can withstand considerable stress. Additionally, the cellulose coating provides excellent arc stability, which results in smoother and more controlled welding processes.

Another advantage is the usability in challenging conditions; E6010 rods perform well in adverse environments, including those with dirty, rusty, or contaminated surfaces. This quality makes them an attractive choice for fieldwork, where preparation time may be limited.

wholesale cellulose welding rod e6010 factory

Furthermore, E6010 rods are cost-effective, especially when procured in wholesale quantities

. Factories specializing in the wholesale production of these rods can offer competitive pricing, thus enabling businesses to maintain budgetary constraints while ensuring high-quality welding materials.The Role of Wholesale Factories

Wholesale factories that produce E6010 cellulose welding rods play a critical role in maintaining the supply chain for welding materials. These manufacturers invest in advanced production technologies and rigorous quality control measures to ensure that each batch of rods meets or exceeds industry standards.

The wholesale model allows these factories to produce large quantities of rods efficiently, which in turn lowers the per-unit cost. This pricing advantage is passed on to the consumers, enabling construction companies, repair shops, and other businesses to purchase welding rods in bulk without compromising on quality.

Moreover, wholesale factories are often equipped to provide customized solutions to their clients. Whether it’s creating rods of specific lengths, diameters, or packaging options, these manufacturers can accommodate various needs to facilitate the diverse applications of E6010 rods.

Conclusion

In conclusion, the significance of wholesale cellulose welding rod E6010 factories cannot be overstated. These establishments are vital producers of a welding material renowned for its strength, versatility, and cost-efficiency. As industries continue to demand high-quality welding solutions, the role of wholesale manufacturers will only grow in importance, ensuring that welders have access to the materials necessary for success in their projects. Whether for large-scale construction or intricate repair work, E6010 cellulose welding rods represent a reliable choice that enhances the quality and durability of welded joints in every application.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025