Wholesale Electrode Welding Manufacturer Offering High-Quality Products at Competitive Prices

The Importance of Wholesale Electrode Welding Manufacturers in Modern Industry

In today's manufacturing landscape, effective welding techniques are critical to the success of various industries, from automotive to construction. Wholesale electrode welding manufacturers play a pivotal role in supplying essential materials for these applications. This article explores the significance, benefits, and trends associated with wholesale electrode welding manufacturers, highlighting why they are indispensable in the modern industrial world.

Understanding Wholesale Electrode Welding

Wholesale electrode welding refers to the mass production and distribution of welding electrodes used in various welding processes, notably shielded metal arc welding (SMAW). These electrodes are essential components that facilitate the joining of metal pieces through electric arc generation, allowing for strong, durable bonds. Wholesale manufacturers provide these products in bulk, ensuring that businesses can maintain adequate supply to meet their production demands.

The Role of Wholesale Manufacturers

Wholesale electrode welding manufacturers serve a crucial function in the supply chain of welding materials. By producing electrodes in large quantities, they can offer competitive pricing and reliable availability. This is particularly important for large-scale projects that require a consistent supply of welding materials to avoid delays and ensure safety standards are met.

Moreover, these manufacturers often provide a variety of electrode types tailored to specific applications. Different metals, positions, and environmental conditions necessitate unique welding rods, and wholesale manufacturers are well-equipped to provide diverse options. These include low-hydrogen electrodes for critical applications, stainless steel electrodes for corrosion resistance, and high-speed options for improved efficiency.

Benefits of Working with Wholesale Manufacturers

1. Cost-Effectiveness One of the primary advantages of sourcing from wholesale manufacturers is cost savings. By purchasing in bulk, companies can reduce per-unit costs and improve their margins. This is especially beneficial for firms engaged in large projects where material costs play a significant role in the overall budget.

wholesale soldadura de electrodo manufacturer

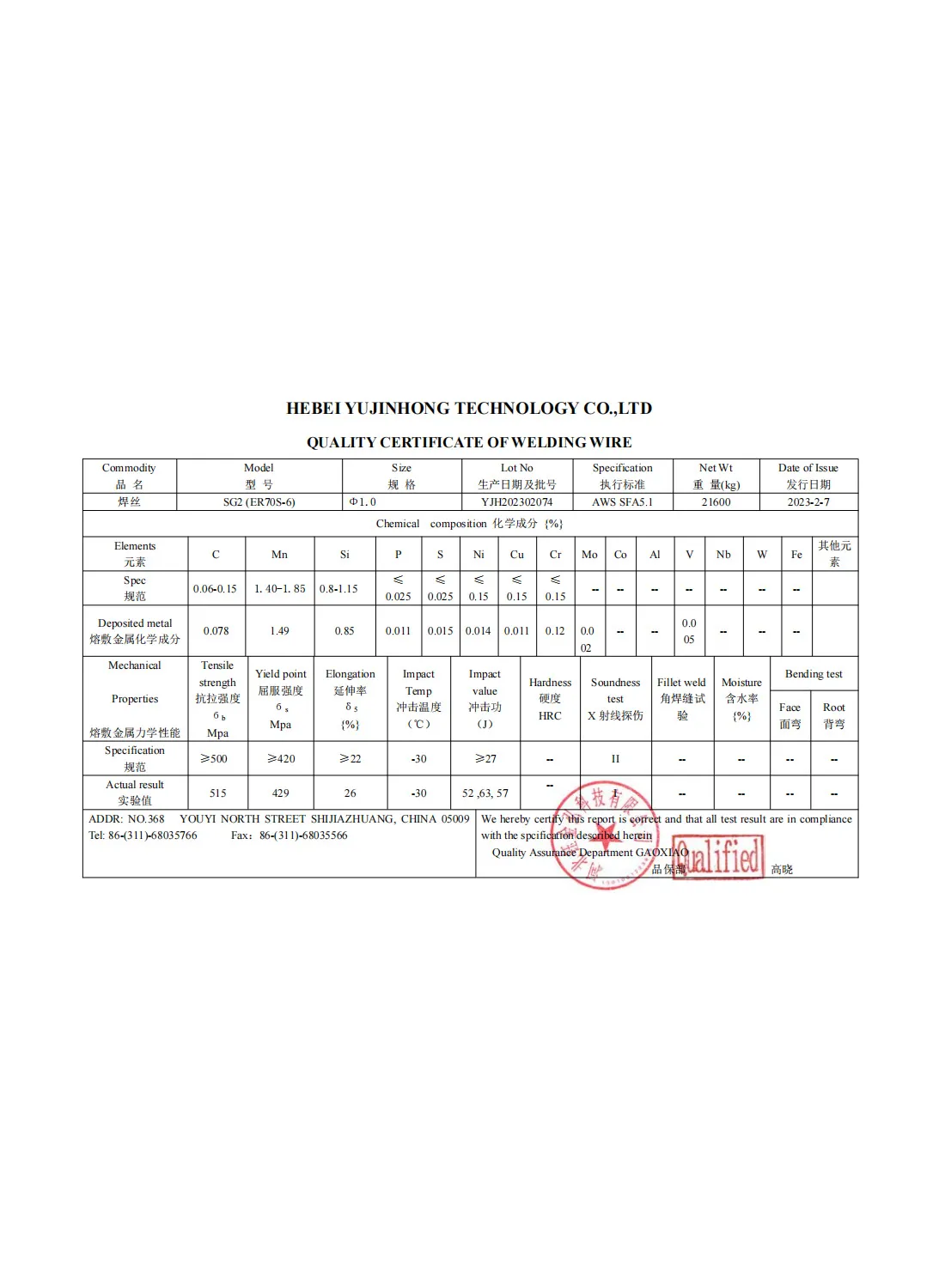

2. Quality Assurance Reputable wholesale electrode manufacturers adhere to stringent quality standards to ensure their products meet industry requirements. This commitment to quality can help businesses avoid costly errors associated with inferior welding materials, such as weak welds or poor finish.

3. Expert Guidance Many wholesale manufacturers offer technical support and expertise in welding processes. This can be invaluable for businesses looking to optimize their welding operations or troubleshoot specific challenges. Access to expert advice can lead to better outcomes and enhanced productivity.

4. Sustainability As the industry moves towards more sustainable practices, many manufacturers are implementing eco-friendly production processes and materials. By partnering with these manufacturers, companies can enhance their sustainable credentials while still obtaining high-quality welding electrodes.

Trends in Electrode Welding Manufacturing

The landscape of electrode welding is continually evolving, driven by technological advancements and changing market demands. Manufacturers are increasingly using automated production techniques to enhance efficiency and consistency. Additionally, the introduction of advanced materials and coatings is improving the performance of welding electrodes, enabling better results in diverse applications.

Furthermore, as industries shift towards greener practices, there is a growing focus on developing electrodes that have lower environmental impact. Manufacturers are exploring options such as reduced hazardous substances in electrode coatings and more sustainable sourcing of raw materials.

Conclusion

Wholesale electrode welding manufacturers are vital players in the manufacturing ecosystem, providing essential materials that enable effective welding across various industries. Their role in offering cost-effective, high-quality products, combined with expert support, makes them indispensable partners for businesses aiming to maintain efficiency and quality in their operations. As the industry embraces technological advancements and sustainability initiatives, these manufacturers will continue to adapt and innovate, reinforcing their importance in modern manufacturing. As we look to the future, it is clear that the relationship between manufacturers and businesses will be crucial for ongoing success in the welding domain.

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025

-

Arc Welding Electrodes AWS E7024 – High Deposition, Smooth FinishNewsJul.30,2025