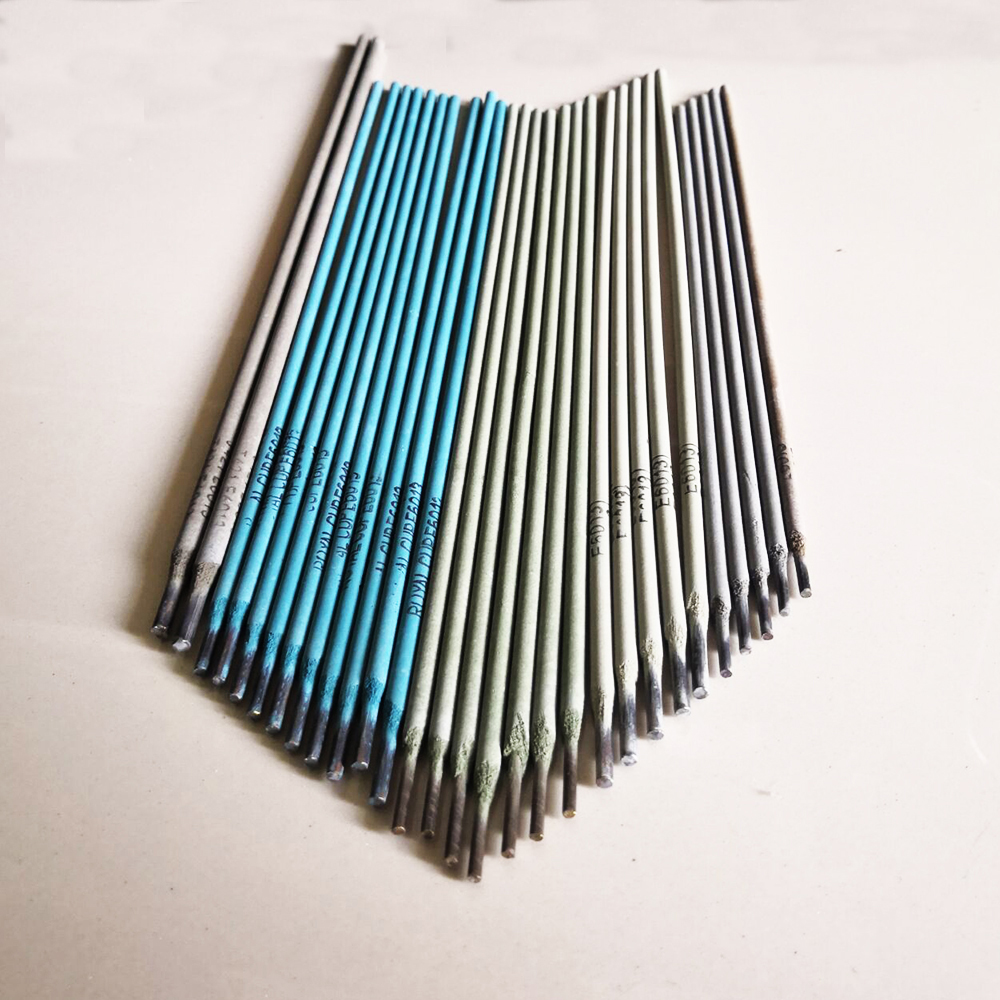

Wholesale Suppliers for 3.25 Welding Electrodes and Related Equipment

Understanding Wholesale Welding Electrode Suppliers A Comprehensive Guide

In the world of manufacturing and construction, welding is a fundamental process that ensures the integrity and durability of various structures and components. Central to welding operations are welding electrodes, which are crucial for creating strong and reliable welds. For businesses engaged in welding or those looking to procure welding materials, understanding wholesale welding electrode suppliers can provide significant advantages in terms of cost, quality, and efficiency.

What Are Welding Electrodes?

Welding electrodes are conductive materials used to join metal pieces together through the process of welding. They serve two primary functions providing the necessary heat for melting the base metals and supplying filler material that becomes part of the weld. There are various types of electrodes, including consumable and non-consumable, with consumable electrodes melting to form the weld, whereas non-consumable electrodes remain intact through the welding process.

The Importance of Wholesale Suppliers

Wholesale welding electrode suppliers focus on providing large quantities of welding materials at competitive prices. These suppliers cater not only to large manufacturing companies but also to smaller businesses that may require welding materials in bulk. By purchasing from wholesale suppliers, companies can benefit in several ways

1. Cost-Effectiveness Wholesale buying often leads to significant savings. Suppliers typically offer lower prices per unit when items are purchased in bulk. This reduction in cost can greatly benefit businesses, allowing them to allocate resources to other areas of operation or to enhance profit margins.

2. Consistency in Quality When dealing with reputable wholesale suppliers, businesses can ensure a consistent quality of materials. This is crucial in welding, where the strength and quality of the weld depend heavily on the materials used. Established suppliers often adhere to strict quality controls and provide products that meet industry standards.

3. Wide Variety Wholesale suppliers usually carry a broad range of welding electrodes, catering to different welding processes such as MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and Stick welding. This variety allows businesses to find the specific types of electrodes they need for particular applications without the hassle of dealing with multiple suppliers.

4. Bulk Availability Companies engaged in large-scale projects require consistent availability of materials to avoid delays. Wholesale suppliers often maintain large inventories, ensuring that businesses can obtain the necessary electrodes promptly and consistently.

wholesale welding electrode 3.25 suppliers

Finding the Right Supplier

When searching for wholesale welding electrode suppliers, businesses should consider several factors

1. Reputation and Reliability It is critical to research suppliers to ascertain their reputation in the market. Looking for reviews, testimonials, and data on their business history can provide insights into their reliability.

2. Certifications Ensure that the suppliers adhere to relevant industry standards and obtain necessary certifications. Certifications can indicate that the materials meet specific quality criteria.

3. Customer Support Strong customer support can be a deciding factor when selecting a supplier. A supplier that offers responsive customer service can assist businesses with any inquiries regarding product specifications, order tracking, and technical support.

4. Competitive Pricing and Terms While cost is a significant factor, it’s also essential to consider payment terms and shipping options. Some suppliers might provide financing options or flexible payment plans that can make a substantial difference for businesses with cash flow considerations.

5. Local vs. International Suppliers Depending on logistics and shipping timelines, businesses should decide whether they prefer to source from local suppliers or international manufacturers. Local suppliers may offer faster delivery times, while international suppliers might provide more competitive pricing due to lower manufacturing costs.

Conclusion

The choice of welding electrode suppliers is pivotal for businesses involved in welding operations. Opting for wholesale suppliers can lead to substantial savings, improved quality consistency, and the ability to meet large-scale production needs more effectively. By conducting thorough research and selecting the right suppliers, businesses can enhance their welding capabilities, ensuring that they deliver high-quality projects while maintaining cost efficiency. Whether it’s for construction, manufacturing, or repair work, understanding the nuances of wholesale welding electrode suppliers can empower companies to make informed purchasing decisions that support their operational goals.

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025