Wholesale Suppliers for E6013 Welding Electrodes and Related Products

The Role of E6013 Welding Electrodes in Modern Welding Applications

In the dynamic landscape of welding technology, the significance of selecting the right materials cannot be overstated. Among the various types of welding electrodes available, the E6013 welding electrode has gained considerable popularity among professionals and hobbyists alike. Famous for its versatility and ease of use, the E6013 is particularly favored in various industrial applications. This article delves into the characteristics, applications, and advantages of E6013 welding electrodes, as well as insights into wholesale suppliers that cater to the growing demand.

Understanding E6013 Welding Electrodes

E6013 is a type of covered electrode commonly used in arc welding processes. The E stands for electrode, while the numbers indicate specific characteristics. 60 signifies the minimum tensile strength of 60,000 psi, 1 means it is suitable for all positions (flat, horizontal, vertical, and overhead), and 3 indicates the type of current it can be used with, namely AC, DC+, and DC-.

The most noteworthy feature of the E6013 is its welding versatility, which makes it ideal for both mild steel and low-alloy materials. The electrode is designed with a rutile coating that facilitates a smooth arc and produces minimal spatter, making it easier for welders to achieve high-quality welds even in challenging conditions.

Applications of E6013 Welding Electrodes

E6013 electrodes find widespread application across various industries, including automotive repair, construction, shipbuilding, and pipeline work. Their ability to perform well in both thick and thin materials makes them suitable for a broad range of welding projects. More specifically, E6013 electrodes are commonly used for

1. Light Fabrication Ideal for light structural work, such as frames and supports, E6013 can efficiently join thin sheets of metal. 2. Maintenance and Repair Due to their versatility, they are often employed in repair work, repairing everything from household appliances to automotive parts. 3. General Steel Fabrication Common in workshops, E6013 electrodes are frequently used to fabricate steel products that require strength and durability.

Advantages of E6013 Welding Electrodes

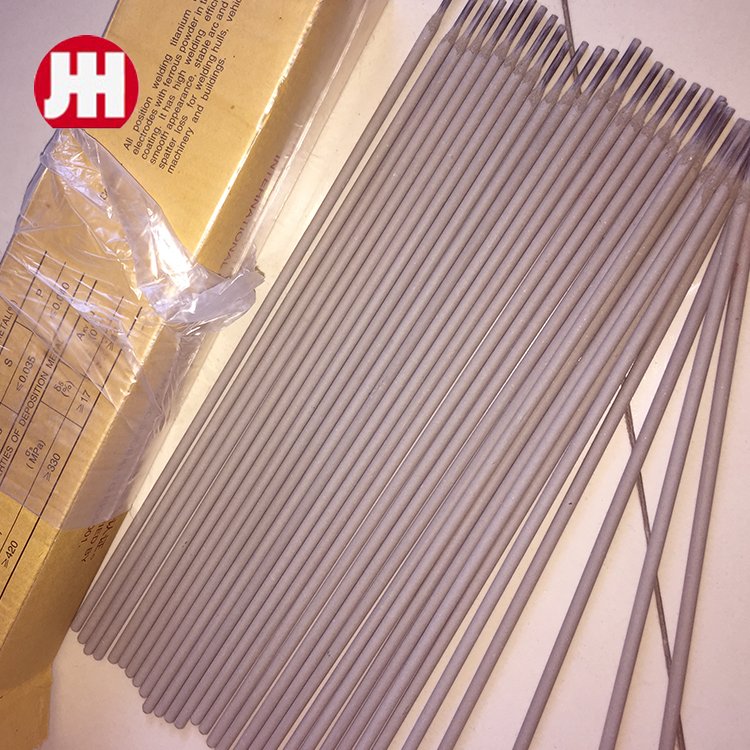

wholesale welding electrode e 6013 suppliers

1. Ease of Use One of the most significant advantages of E6013 welding electrodes is their weldability. They are easy to handle, which makes them an excellent choice for both novice and experienced welders. 2. Good Appearance E6013 welds are known for their aesthetically pleasing finish, which is important in applications where the appearance of the weld is critical.

3. Excellent Slag Removal The electrodes produce minimal slag that is easy to remove, resulting in cleaner finished products.

4. Wide Availability Given the high demand for E6013 electrodes, they are readily available in the market. This accessibility is supported by a vast network of wholesale suppliers.

Wholesale Suppliers of E6013 Welding Electrodes

With the increasing demand for high-quality welding materials, finding reliable wholesale suppliers of E6013 welding electrodes is essential for businesses looking to maintain production quality. Wholesale suppliers typically offer competitive prices and bulk purchasing options, making it easier for construction firms and fabrication shops to stock up on essential supplies.

When looking for wholesale suppliers, consider factors such as product quality, delivery times, and customer service. Suppliers with a strong reputation in the industry are more likely to provide consistent product quality and reliable delivery. Additionally, many reputable suppliers offer technical support to help customers choose the right electrodes for their specific welding needs.

Conclusion

The E6013 welding electrode has established itself as one of the most versatile and essential tools in the welding profession. Its ease of use, strong performance across various applications, and availability through wholesale suppliers make it a favored choice for many. As industries continue to evolve, the demand for reliable and efficient welding solutions like the E6013 will undoubtedly grow. For welders looking to optimize their operations, investing in E6013 welding electrodes is a smart move that promises durability, reliability, and impressive results.

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025