china er70s-6 welding wire 1.2mm

Understanding China ER70S-6 Welding Wire 1.2mm An Essential Guide

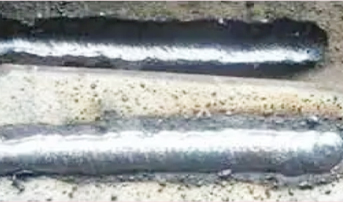

Welding is an integral part of manufacturing and construction, and selecting the right materials is crucial for ensuring quality and durability. Among the various options available, the China ER70S-6 welding wire, particularly in the 1.2mm diameter, stands out as a preferred choice for many professionals in the industry. This article delves into the properties, applications, and advantages of using ER70S-6 welding wire.

What is ER70S-6 Welding Wire?

ER70S-6 is a copper-coated, solid welding wire commonly utilized in MIG (Metal Inert Gas) welding processes. The ER stands for Electrode Rod, while the 70 indicates a minimum tensile strength of 70,000 psi. The S implies that it is a solid wire, and the 6 designates its ability to handle various conditions and materials effectively. The 1.2mm diameter of the wire makes it suitable for a range of welding applications, providing a balance between strength and ease of use.

Properties and Benefits

One of the standout characteristics of ER70S-6 welding wire is its excellent mechanical properties. It is designed to work well with clean and adequately prepared surfaces, making it ideal for welding mild steel and various types of low alloy steel. The wire contains higher levels of manganese and silicon, which enhance its ability to perform well in challenging environments, including those with dirty or oily surfaces.

china er70s-6 welding wire 1.2mm

Another significant advantage of ER70S-6 is its versatility. This wire can be used for both single and multi-pass welding, making it suitable for different thicknesses of metal. Its ability to produce a smooth and clean weld bead minimizes the need for extensive post-weld cleaning, saving time and resources.

Applications

The applications of China ER70S-6 welding wire are extensive. It is commonly used in industries such as construction, automotive, and shipbuilding. Professionals often choose this wire for welding applications involving structural components, frames, and other steel elements requiring strong and durable joints. Additionally, its adaptability allows it to be utilized in various welding positions, further enhancing its utility.

Conclusion

In summary, China ER70S-6 welding wire in a 1.2mm diameter is an excellent choice for professionals seeking reliable and high-quality welding solutions. Its strong mechanical properties, versatility in applications, and ability to produce clean welds make it a preferred option across multiple industries. Whether you are involved in fabrication, repairs, or structural work, investing in ER70S-6 welding wire can significantly enhance the quality and efficiency of your welding projects. As the demand for durable and efficient welding materials continues to grow, ER70S-6 stands as a reliable solution for tackling a variety of welding challenges.

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025