china cast iron mig wire factory

The Rise of China’s Cast Iron MIG Wire Industry

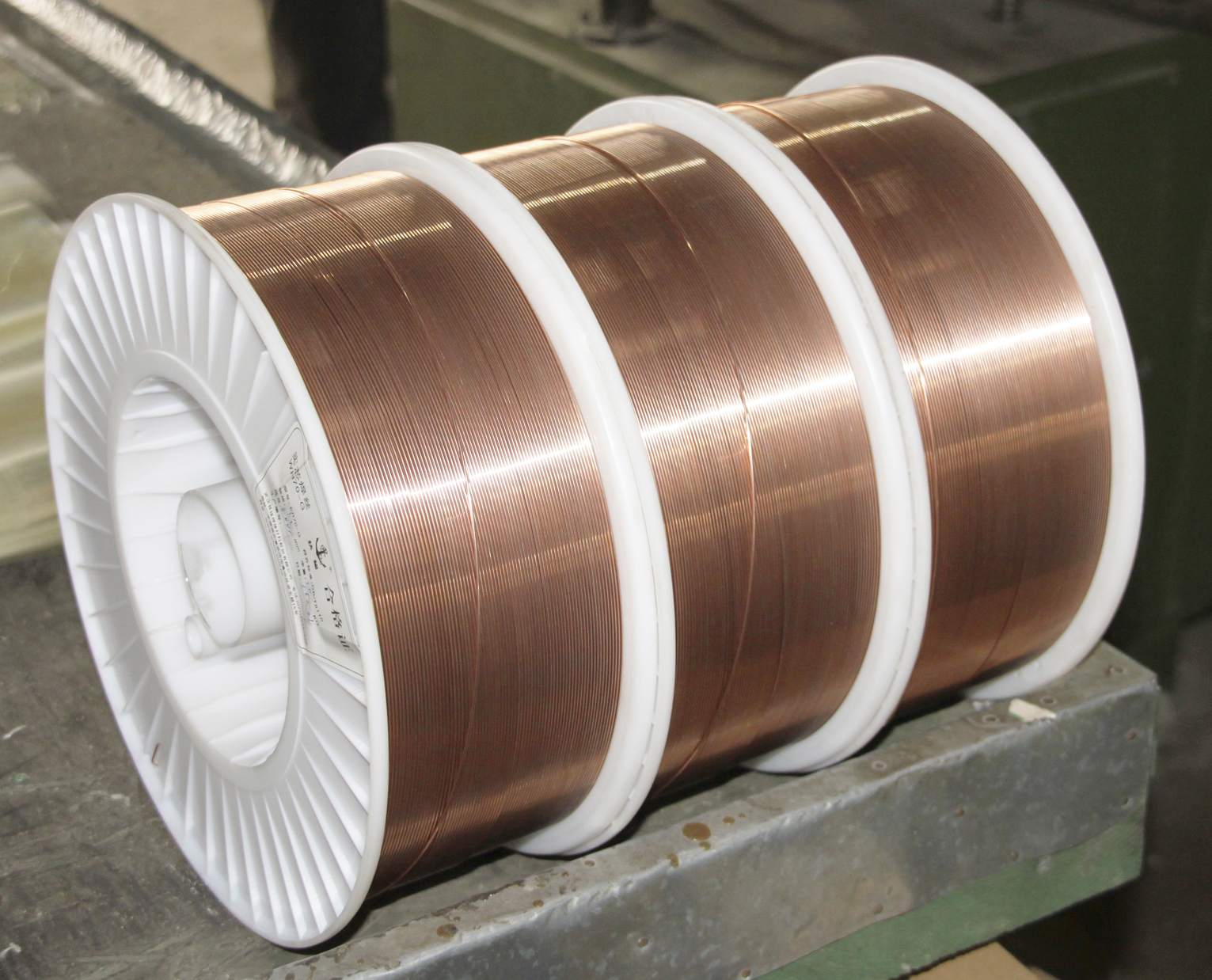

In recent years, China's manufacturing sector has witnessed significant transformation, particularly in specialized materials such as cast iron MIG (Metal Inert Gas) wires. As industries across the globe increasingly rely on this versatile welding process, China has emerged as one of the leading producers of high-quality cast iron MIG welding wires. This article explores the factors driving this growth, the role of factories in the production process, and the implications for the global market.

Understanding Cast Iron MIG Wires

Cast iron MIG wires are essential for welding applications that involve cast iron components, commonly found in automotive, machinery, and construction industries. These wires are designed to withstand the unique thermal and mechanical properties of cast iron, making them indispensable for ensuring structural integrity during welding processes. The ability to produce MIG wires that meet varying specifications has positioned China as a preferred choice for manufacturers worldwide.

Factors Driving Growth

Several factors contribute to the growth of China's cast iron MIG wire industry. Firstly, China's robust industrial base and availability of resources have led to economies of scale. With an extensive supply chain and advanced manufacturing technologies, factories in China can produce high-quality MIG wires at competitive prices. This cost-effectiveness is vital for companies looking to optimize their production costs without compromising on quality.

Secondly, the increasing demand for welding materials in infrastructure projects and manufacturing processes has fueled the expansion of this sector. The global push for modernization and development in various regions, especially in emerging economies, heightens the need for reliable welding solutions.

Moreover, technological advancements in welding processes and equipment have enhanced the efficiency and effectiveness of cast iron MIG wires. Chinese manufacturers have adopted innovative practices, investing in automation and R&D to improve product quality and performance, which further bolsters their position in the market.

The Role of Factories

china cast iron mig wire factory

China's cast iron MIG wire factories are at the forefront of this industrial evolution. These facilities employ state-of-the-art machinery and skilled labor to ensure the production of superior products. Many factories have adopted international quality standards, such as ISO certifications, to meet the rigorous demands of global markets.

Quality assurance processes, including rigorous testing of tensile strength, ductility, and corrosion resistance, are integral to production. By focusing on high standards, Chinese manufacturers have garnered trust among international customers, establishing long-term relationships that foster collaboration and innovation.

Additionally, many factories emphasize sustainability and eco-friendly practices in their operations. The integration of green technologies and sustainable sourcing of raw materials aligns with global efforts to reduce carbon footprints and promote environmental responsibility.

Implications for the Global Market

The rise of China’s cast iron MIG wire factories has significant implications for the global welding materials market. As prices continue to remain competitive, manufacturers in other regions may face challenges maintaining market share. However, this also presents an opportunity for international partnerships and collaboration, as businesses seek to leverage China’s expertise and capabilities.

Moreover, an increase in competition necessitates continuous innovation and improvement across the industry, pushing producers to enhance their offerings constantly. This environment encourages technological advancements that can provide better solutions for customers.

Conclusion

In conclusion, China's prominence in the cast iron MIG wire industry highlights the country's manufacturing prowess and its essential role in the global market. The combination of resource availability, technological advancement, and a focus on quality has established China as a leader in this sector. As the demand for reliable welding solutions continues to grow, Chinese factories will likely remain pivotal, shaping the future of the welding materials industry worldwide. The ongoing evolution in this field promises to bring forth innovations that will benefit manufacturers and consumers alike, pushing the boundaries of what’s possible in welding technology.

-

Wholesale E6013 Welding Electrodes Factories Durable & AffordableNewsMay.18,2025

-

SG2 TIG Welding Wire 2.4mm - High Durability & Precision Welding SolutionNewsMay.18,2025

-

High-Quality 025 Flux Cored Welding Wire Wholesale Factory & SupplierNewsMay.18,2025

-

Gasless Stainless Steel MIG Welding Wire High-Quality Flux-Core SolutionNewsMay.17,2025

-

E6011 Welding Rod Meaning High Penetration & Versatile UseNewsMay.17,2025

-

High-Quality CS to SS Welding Electrodes 7016 Durable & Corrosion-ResistantNewsMay.16,2025