china mig weld electrode manufacturers

China MIG Weld Electrode Manufacturers Pioneers of Innovation and Quality

In the ever-evolving landscape of welding technology, the importance of high-quality MIG (Metal Inert Gas) weld electrodes cannot be overstated. These vital components of the welding process are essential for achieving strong, reliable welds across various applications ranging from construction to manufacturing. Among the global leaders in MIG electrode production, China stands out, housing a plethora of manufacturers that have transformed the welding industry through innovation, quality, and competitive pricing.

The Chinese Manufacturing Landscape

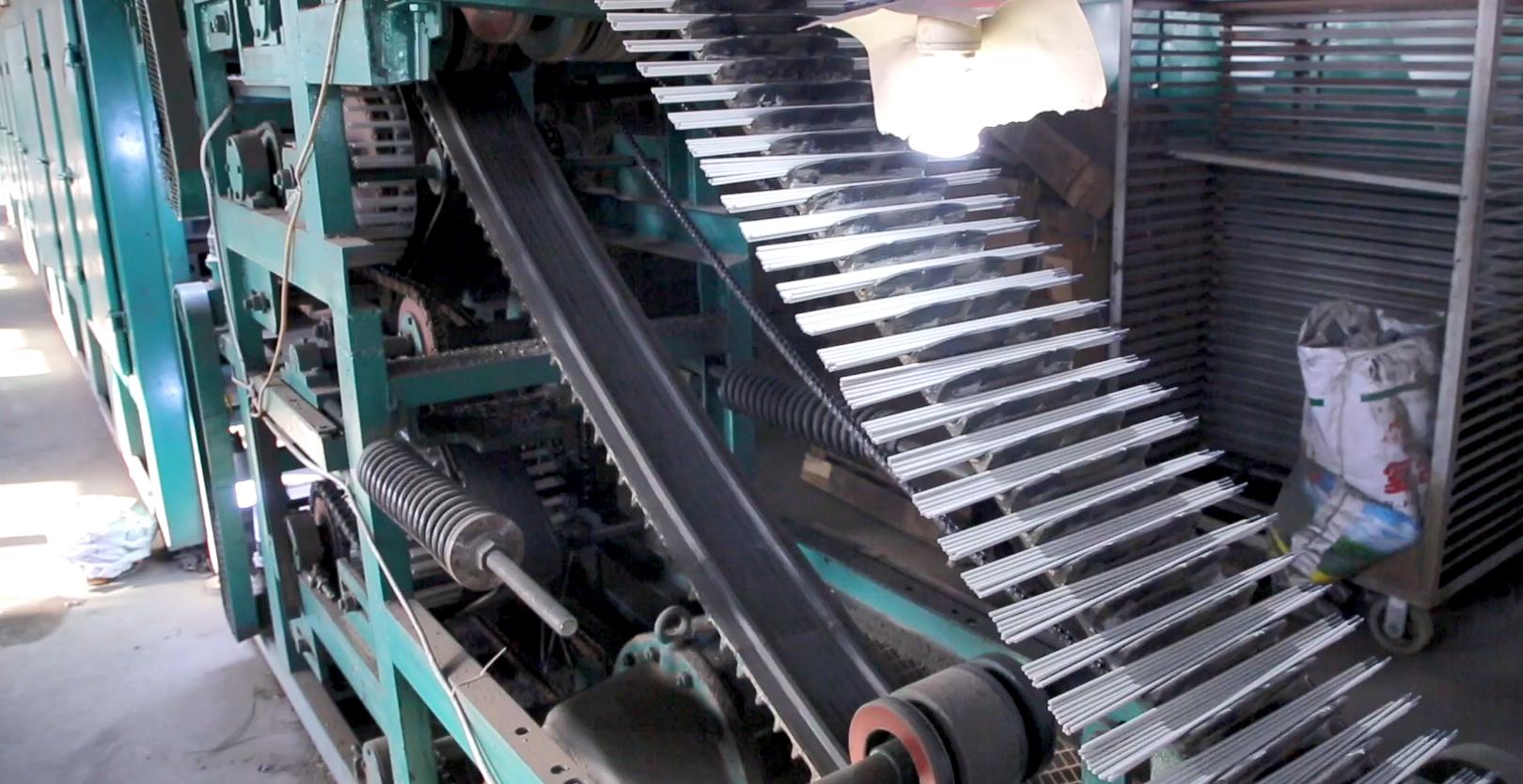

China's ascendancy in the global market can be attributed to its extensive manufacturing capabilities and a commitment to high standards. The country is home to numerous MIG weld electrode manufacturers equipped with advanced technology and skilled labor. This significant investment in production facilities and R&D has propelled Chinese manufacturers to the forefront of the welding industry.

Chinese MIG weld electrode companies produce a wide array of products tailored to different welding processes and materials, including carbon steel, stainless steel, and aluminum. These electrodes are crucial for various industries, including automotive, shipbuilding, construction, and general fabrication. By offering an extensive product portfolio, these manufacturers meet the diverse needs of their global clientele, ensuring that they remain competitive in an increasingly challenging marketplace.

Quality Assurance and Compliance

Quality is a paramount concern for any welding operation. Reputable Chinese MIG weld electrode manufacturers adhere to strict quality control protocols and international standards such as ISO 9001 and AWS (American Welding Society) certifications. This compliance ensures that their products meet safety and performance specifications, providing peace of mind for welders worldwide.

Many of these manufacturers invest heavily in research and development to advance their products continuously. By employing state-of-the-art technology and innovative techniques, they enhance the performance characteristics of their MIG electrodes, such as improved arc stability, reduced spatter, and greater penetration. The focus on quality and innovation not only elevates the products but also the safety and efficiency of welding operations across various sectors.

Competitive Pricing and Global Reach

china mig weld electrode manufacturers

China's vast production capabilities enable its MIG weld electrode manufacturers to offer competitive pricing without compromising quality. This affordability makes Chinese weld electrodes an attractive option for businesses operating on tight budgets or those looking to maximize their operational efficiency. Moreover, the extensive supply chain networks established by these manufacturers facilitate prompt and cost-effective shipping to international markets.

Chinese manufacturers have successfully penetrated various global markets, establishing partnerships and distribution channels across continents. Their ability to cater to different regional demands, preferences, and standards has fueled their international growth. As a result, many companies worldwide have turned to Chinese MIG weld electrodes as reliable alternatives to local and more expensive products.

Environmental Sustainability Initiatives

In recent years, environmental sustainability has become a critical consideration in manufacturing processes. Chinese MIG weld electrode manufacturers are increasingly embracing green initiatives by adopting eco-friendly practices. This includes utilizing sustainable raw materials, minimizing waste during production, and reducing energy consumption.

Moreover, these manufacturers are exploring ways to produce biodegradable welding materials and enhance the recyclability of their products. By prioritizing sustainability, manufacturers not only comply with regulations but also appeal to the growing number of environmentally conscious consumers and businesses.

Conclusion

As the demand for MIG welding continues to grow, the role of Chinese manufacturers in the global market becomes increasingly significant. Their commitment to quality, innovation, and competitive pricing dynamically shapes the welding industry. Furthermore, the emphasis on sustainability underscores the manufacturers’ dedication to environmental stewardship while meeting the needs of modern welding operations.

With their established reputation, advanced technology, and focus on customer satisfaction, Chinese MIG weld electrode manufacturers are poised to remain at the forefront of the welding industry. As they continue to adapt to market demands and technological advancements, they will undoubtedly play a crucial role in defining the future of welding worldwide. Whether for small-scale fabricators or large industrial players, the availability of high-quality MIG weld electrodes from China ensures that the art of welding continues to thrive with unmatched strength and reliability.

-

J506 Welding Rod: High-Strength, Crack-Resistant ElectrodeNewsAug.23,2025

-

E71T-1 Shielding Gas for Superior Welding Quality & EfficiencyNewsAug.22,2025

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025