china spot welding electrode

The Role and Importance of Spot Welding Electrodes in China’s Manufacturing Industry

Spot welding is a widely used technique in the automotive and electronics industries, where two or more metal sheets are joined together through localized heating, usually from a powerful electrical current. This process relies heavily on the use of spot welding electrodes, which play a critical role in ensuring the efficiency and quality of the weld.

Understanding Spot Welding Electrodes

Spot welding electrodes are made from highly conductive materials such as copper or alloys, which enable them to transmit the electrical current needed to create welds. These electrodes are designed to withstand high temperatures and pressures while maintaining their integrity throughout the welding process. They are typically composed of two parts the electrode cap, which contacts the workpieces, and the electrode body, which conducts electricity.

In the context of China’s manufacturing industry, the proper selection of spot welding electrodes is paramount. The country has become one of the largest manufacturers in the world, with industries ranging from automotive to electronics booming. Thus, the demand for high-quality spot welding electrodes has surged.

Types of Spot Welding Electrodes

There are various types of spot welding electrodes available in the market, each suited for different applications based on factors such as the thickness and type of metal being welded. Generally, there are two main categories of electrodes copper alloy electrodes and reactive metal electrodes.

1. Copper Alloy Electrodes These are the most common types of electrodes used in spot welding. They have excellent thermal and electrical conductivity, making them ideal for welding applications involving thin metal sheets. Copper-bismuth and copper-chromium are popular choices in this category due to their strength and durability.

2. Reactive Metal Electrodes These electrodes are often used for welding high-strength materials, such as stainless steel or high-carbon steels. They have a higher resistance to heat and wear, which allows them to perform better under extreme conditions.

The Manufacturing Process in China

china spot welding electrode

China boasts a substantial electrode manufacturing industry that focuses on producing high-quality welding tools to cater to both domestic and international markets. Through advanced manufacturing techniques, such as precision casting and automated machining, Chinese manufacturers ensure that their electrodes meet rigorous quality standards.

Moreover, with the rise of Industry 4.0, Chinese manufacturers are increasingly implementing smart manufacturing practices. This evolution not only enhances production efficiency but also leads to improved product quality. The integration of IoT devices and real-time monitoring systems allows manufacturers to track electrode wear and lifespan, which can significantly reduce operational costs and downtime.

Quality Control and Standards

Quality control is a fundamental aspect of electrode manufacturing. In China, various standards such as the GB standard (National Standard of the People's Republic of China) ensure that welding electrodes are tested for criteria including hardness, wear resistance, and conductivity. Manufacturers invest in quality assurance systems to maintain compliance with these standards, helping to enhance the credibility of Chinese-made welding products globally.

Challenges Facing the Industry

Despite its strengths, the spot welding electrode industry in China faces several challenges. One of the primary concerns is the fluctuation in raw material prices, particularly copper. This affects production costs and can lead to price volatility in the market. Additionally, as automation becomes more prevalent, manufacturers must balance the integration of new technologies while maintaining skilled labor for critical quality control processes.

Moreover, environmental regulations are becoming increasingly stringent, requiring manufacturers to adopt greener practices in their production processes. This shift towards sustainability is essential not only for regulatory compliance but also for meeting the growing consumer demand for environmentally friendly products.

Conclusion

Spot welding electrodes are essential components in the manufacturing landscape, particularly in China, where the industry continues to grow and evolve. The development of advanced materials and technologies is pivotal for enhancing the performance and longevity of welding electrodes. With a focus on quality, innovation, and sustainability, China’s spot welding electrode manufacturers are well-positioned to meet the demands of diverse industries worldwide. As the manufacturing sector continues to adapt to new challenges and opportunities, the importance of high-quality spot welding electrodes will undoubtedly remain paramount.

-

Premium Cast Iron Welding Electrode Strong, Durable Bonds EfficientlyNewsJun.03,2025

-

Small Portable Flux Core Welder for Efficient MetalworkNewsJun.03,2025

-

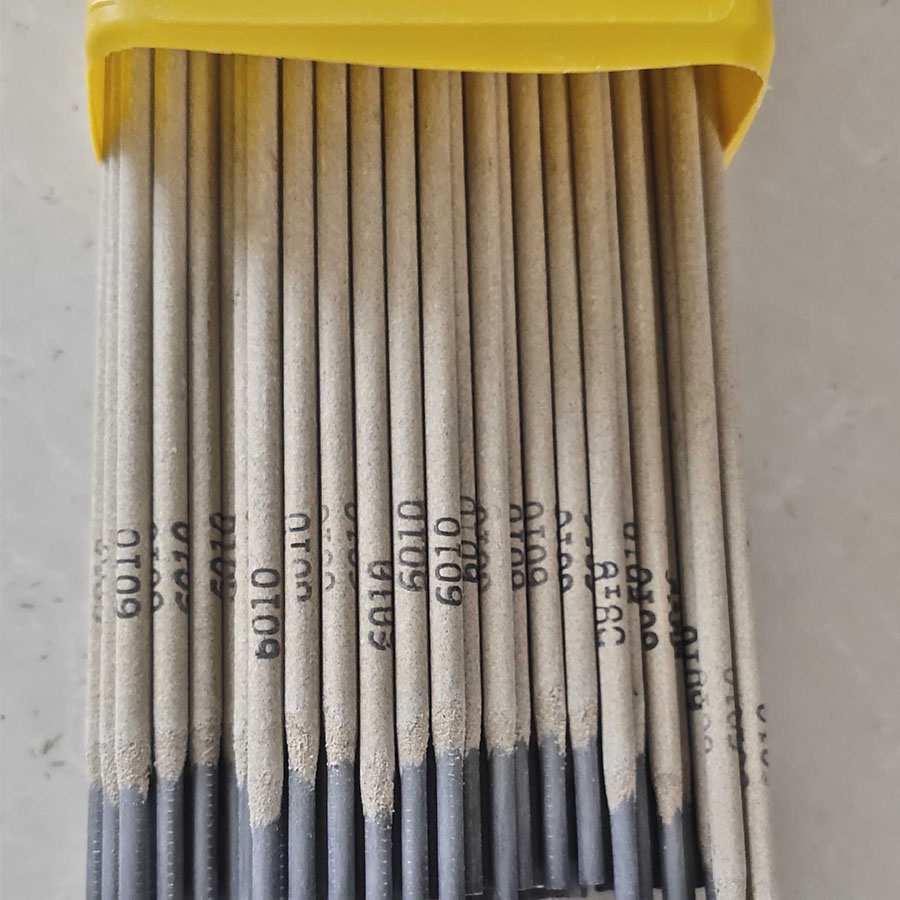

Premium 6010 Welding Rod for Sale High Quality & DurableNewsJun.03,2025

-

E7024 Welding Rod High-Deposition Arc Electrodes for Durable JointsNewsJun.03,2025

-

China E6011 Welding Rod 2.5mm - High Strength & Durable Factory DirectNewsJun.03,2025

-

NI CL & 7016 Welding Rods for Pipe Welding China SupplierNewsJun.03,2025