Premium MIG Welder Wire Manufacturing | Quality Welding Supplies

When discussing the world of welding, particularly within the context of MIG (Metal Inert Gas) welding, one cannot overlook the crucial role that MIG welder wire factories play in shaping the industry. These factories are dedicated to producing high-quality welding wires that are essential for achieving strong, durable, and aesthetically pleasing welds in various applications.

MIG welding is favored in many sectors due to its efficiency and versatility. One of the key components that contribute to its success is the welding wire. MIG welding wire not only acts as a filler material but also provides the necessary shielding gas through the process of combining with the electric arc to produce molten metal. For this reason, the quality of the MIG wire is paramount. It must be manufactured to precise specifications to ensure it can withstand the rigors of industrial applications.

.

Once the raw materials are sourced, they undergo a series of processes that include melting, extrusion, and cooling. The extrusion process is particularly important as it determines the diameter and shape of the wire. High-quality MIG wires are available in various diameters, allowing welders to choose the right one for their specific tasks. After extrusion, the wires are often subjected to heat treatment processes to enhance their mechanical properties.

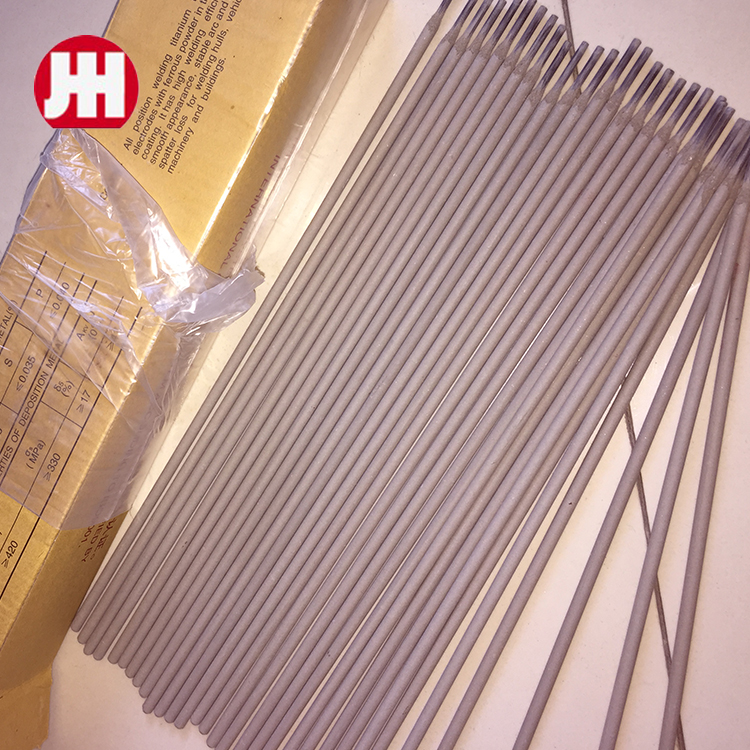

mig welder wire factories

Quality control is a critical aspect of manufacturing MIG welding wire. Factories conduct rigorous testing, including tensile tests, elongation tests, and microscopic examinations, to ensure each batch meets the necessary industry standards. This commitment to quality not only enhances the performance of the wire but also boosts the confidence of welders who rely on these products in demanding situations.

In addition to high-quality production, MIG welder wire factories are increasingly adopting sustainable practices. With a growing emphasis on environmental responsibility, many factories are exploring ways to reduce waste, recycle materials, and implement energy-efficient processes. This shift not only benefits the environment but can also lead to cost savings and improved operational efficiency.

In conclusion, the role of MIG welder wire factories is indispensable in the welding industry. Through careful selection of materials, advanced manufacturing techniques, and stringent quality control measures, these facilities produce the high-performance wires that enable welders to execute their craft effectively. With ongoing innovations and a commitment to sustainability, these factories will continue to be at the forefront of the welding supply chain, driving the industry toward a brighter, more efficient future.

-

3.25mm Welding Electrodes High-Performance, Durable Wholesale FactoryNewsMay.19,2025

-

AWS A5.1 E6010 Welding Rods Durable All-Position ElectrodesNewsMay.19,2025

-

Wholesale E6013 Welding Electrodes Factories Durable & AffordableNewsMay.18,2025

-

SG2 TIG Welding Wire 2.4mm - High Durability & Precision Welding SolutionNewsMay.18,2025

-

High-Quality 025 Flux Cored Welding Wire Wholesale Factory & SupplierNewsMay.18,2025

-

Gasless Stainless Steel MIG Welding Wire High-Quality Flux-Core SolutionNewsMay.17,2025