Quality Welding Rod Suppliers - Reliable Welding Solutions

Welding Rod Suppliers Ensuring Quality and Reliability

In the world of metal fabrication and construction, the significance of welding rods cannot be overstated. They play a crucial role in the welding process, acting as the filler material that joins metals together. Whether you’re engaged in a small DIY project or a large industrial operation, finding the right welding rod supplier is key to achieving quality results. This article explores the importance of selecting reliable welding rod suppliers and what to look for in a partner.

Understanding Welding Rods

Welding rods come in various types and specifications, each designed for specific applications. They include solid wires, flux-cored wires, and stick electrodes, among others. The choice of welding rod largely depends on factors like the type of metals being welded, the welding technique used, and the environment in which the welding is performed. The quality of these rods directly impacts the strength and durability of the welded joints.

The Importance of Quality Suppliers

When it comes to welding, quality matters. Subpar rods can lead to weak welds, which may compromise the integrity of the project. Quality suppliers understand this and provide products that meet industry standards. They source materials from reputable manufacturers and conduct rigorous quality checks to ensure compliance. By opting for reliable suppliers, companies can reduce the risk of defects and rework, saving time and money.

What to Look for in a Welding Rod Supplier

welding rod suppliers supplier

1. Product Range A good supplier should offer a comprehensive range of welding rods suitable for various applications. This includes different materials, coatings, and sizes. This ensures that customers can find exactly what they need for their specific project.

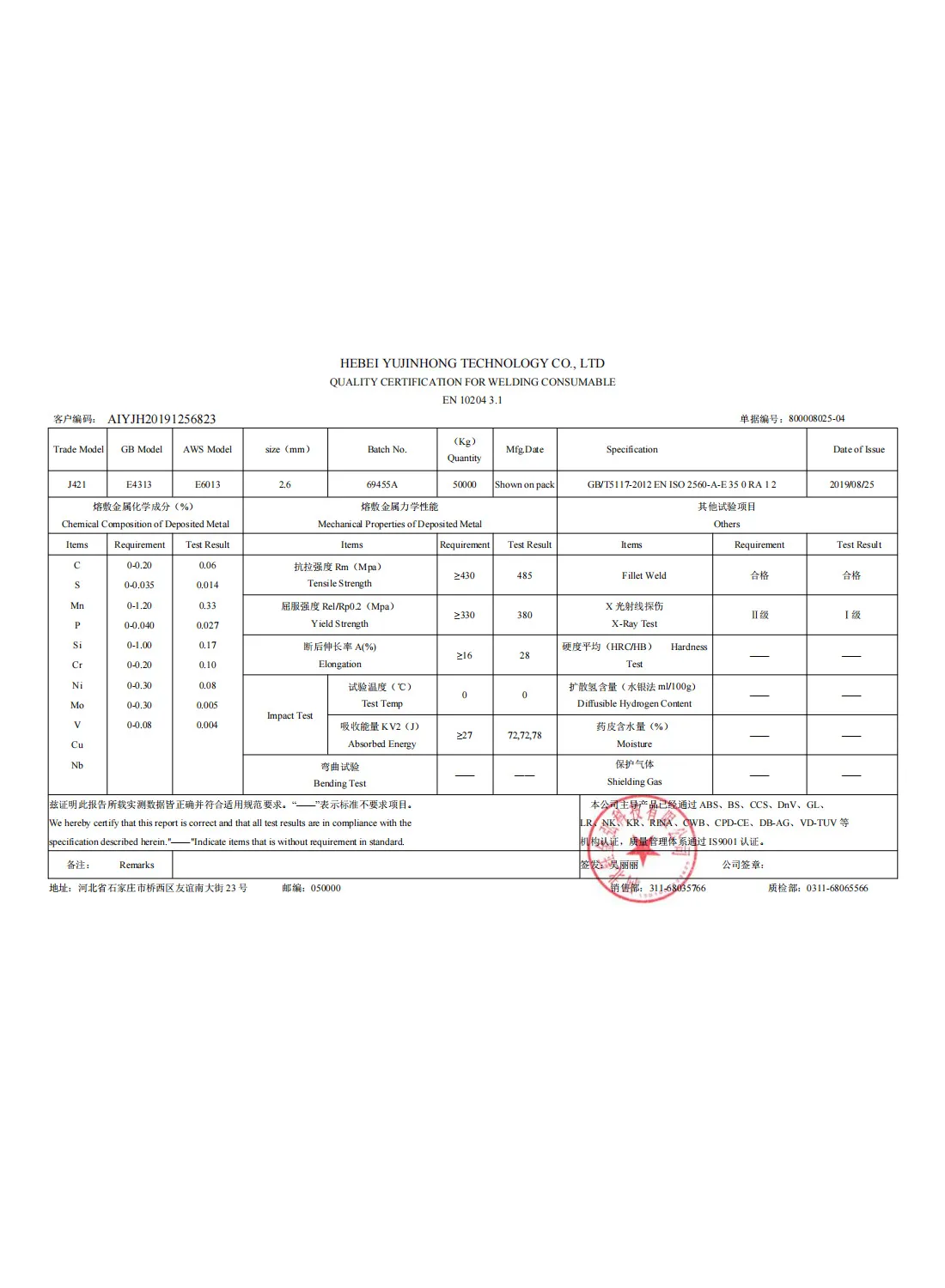

2. Quality Assurance Verify that the supplier has quality assurance processes in place. Look for certifications such as ISO standards or compliance with AWS (American Welding Society) guidelines. These certifications indicate that the supplier adheres to stringent quality control measures.

3. Customer Support Exceptional customer service is crucial in building a lasting partnership. A reliable supplier should offer knowledgeable staff who can assist with product selection and provide technical support as needed. This helps welders make informed choices and troubleshoot any issues that may arise.

4. Reputation and Reviews Research potential suppliers by checking their reputation within the industry. Reading reviews from other customers can provide insights into their reliability and service quality. Suppliers with a strong track record in customer satisfaction are often the best choice.

5. Pricing and Availability While cost should not be the sole determining factor, it is essential to find a supplier that offers competitive pricing without compromising on quality. Additionally, timely availability of products can significantly impact project timelines, so ensure the supplier can meet your demands promptly.

Conclusion

Selecting the right welding rod supplier is a crucial step in ensuring the success of your welding projects. By prioritizing quality, product variety, customer support, and a good reputation, you can forge a partnership that enhances your welding capabilities and helps you achieve exceptional results. As the industry continues to evolve, aligning with reputable suppliers will keep you equipped with the best materials and technology at your disposal.

-

SS 309 Welding Electrode Supplier High-Quality Stainless Steel RodsNewsMay.09,2025

-

3/32 Welding Rod 7016 for Pipes China Supplier High DurabilityNewsMay.09,2025

-

2.5mm Stainless Steel Welding Rods High-Strength & Corrosion-ResistantNewsMay.08,2025

-

Premium 2.5mm SS Welding Rods High-Strength Pipe Welding SolutionsNewsMay.08,2025

-

China Welding Steel Rods & Electrodes High-Quality Manufacturers & FactoriesNewsMay.07,2025

-

High-Strength Welding Rod 60 13 China Pipe Welding SupplierNewsMay.07,2025