Oca . 21, 2025 03:20

Back to list

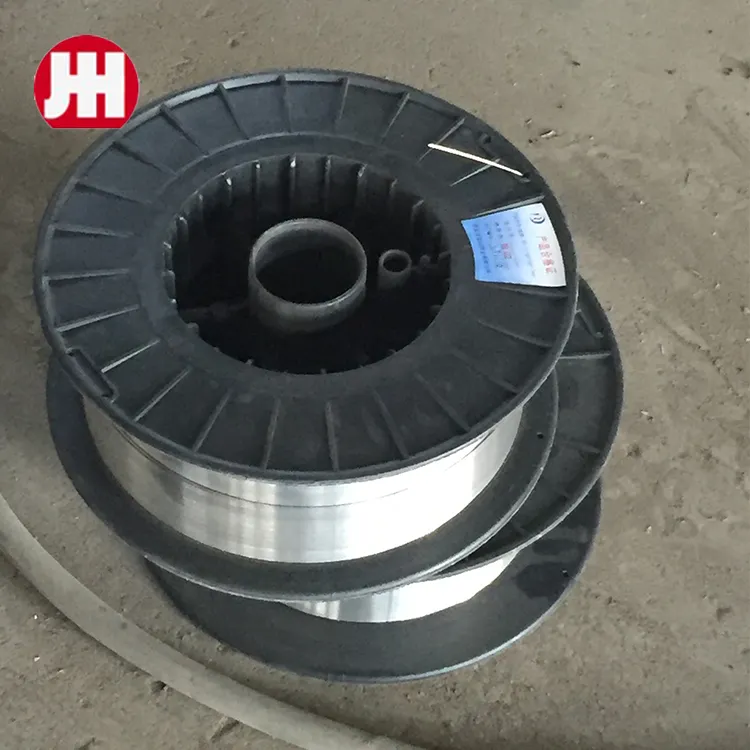

j422 welding rod

Welding electrodes play a vital role in ensuring the integrity and quality of metal joints. Among various types of electrodes, the J422 3.2 electrode is particularly noteworthy for its performance and versatility in the field of welding. Its growing popularity is driven by a combination of technical precision, affordability, and adaptability to different welding needs.

The reliability of the J422 3.2 electrode is further validated through rigorous testing and certifications. Manufacturers produce these electrodes in compliance with international standards, ensuring welders receive a consistent product. The certifications often include assessments of the electrode’s chemical composition and mechanical properties, carried out by authoritative bodies to assure end-users of the quality and reliability of the welded joints. In practical terms, the electrode's usability extends to various environments, inclusive of pipeline construction, industrial fabrication, maintenance and repair businesses, and even in DIY home projects. This versatility is partly due to its ability to perform in vertical and overhead positions, providing further scope for welders to execute operations in challenging orientations successfully. Trust in J422 3.2 electrodes is not solely based on technical specifications and certifications, but also cemented through real-world performance and longstanding industry reputation. Many welding professionals testify to the durability and reliability of these electrodes in varied conditions, reinforcing their status as trustworthy components in welding consumables. In conclusion, the J422 3.2 welding electrodes stand out for good reason. They combine excellent usability, robust mechanical properties, and high standards of quality assurance, making them an optimal choice for a wide range of welding applications. Whether utilized for large-scale industrial projects or smaller, precision-driven undertakings, they offer a balanced and efficient solution for the professional welder's toolkit. As such, they continue to be a vital asset in the welding industry, trusted by experts for their performance, reliability, and cost-effectiveness.

The reliability of the J422 3.2 electrode is further validated through rigorous testing and certifications. Manufacturers produce these electrodes in compliance with international standards, ensuring welders receive a consistent product. The certifications often include assessments of the electrode’s chemical composition and mechanical properties, carried out by authoritative bodies to assure end-users of the quality and reliability of the welded joints. In practical terms, the electrode's usability extends to various environments, inclusive of pipeline construction, industrial fabrication, maintenance and repair businesses, and even in DIY home projects. This versatility is partly due to its ability to perform in vertical and overhead positions, providing further scope for welders to execute operations in challenging orientations successfully. Trust in J422 3.2 electrodes is not solely based on technical specifications and certifications, but also cemented through real-world performance and longstanding industry reputation. Many welding professionals testify to the durability and reliability of these electrodes in varied conditions, reinforcing their status as trustworthy components in welding consumables. In conclusion, the J422 3.2 welding electrodes stand out for good reason. They combine excellent usability, robust mechanical properties, and high standards of quality assurance, making them an optimal choice for a wide range of welding applications. Whether utilized for large-scale industrial projects or smaller, precision-driven undertakings, they offer a balanced and efficient solution for the professional welder's toolkit. As such, they continue to be a vital asset in the welding industry, trusted by experts for their performance, reliability, and cost-effectiveness.

Previous:

Latest news

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025