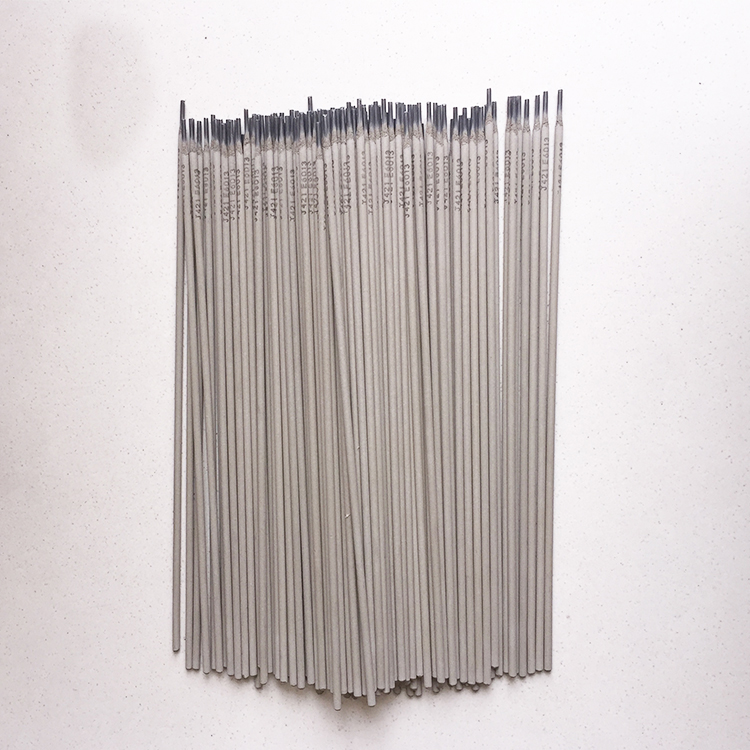

welding wire er70s-6 15kg factory

Understanding ER70S-6 Welding Wire and Its Applications

Welding is a crucial process in various industries, from construction to manufacturing. The choice of welding wire plays a significant role in determining the quality and durability of the weld. Among the various options available, ER70S-6 welding wire is widely recognized for its versatility and performance characteristics. This article delves into the specifics of ER70S-6 welding wire, highlighting its features, applications, and the importance of sourcing it from a reputable factory.

What is ER70S-6 Welding Wire?

ER70S-6 is a type of MIG (Metal Inert Gas) welding wire, characterized by its low alloy steel composition. The ER denotes electrode or filler rod, while the 70 signifies a minimum tensile strength of 70,000 psi. The S indicates that the wire is solid, and the -6 points to the wire's specific chemical composition and mechanical properties, particularly the addition of deoxidizers like manganese and silicon.

This welding wire is commonly used in short-circuiting and spray transfer processes, making it suitable for a variety of welding positions. Its excellent arc stability and smooth feeding ability contribute to its popularity among welders.

Key Features of ER70S-6 Welding Wire

1. Composition ER70S-6 typically contains a balanced mix of carbon, manganese, silicon, and small amounts of copper and chromium. This blend enhances the wire's performance, making it suitable for welding mild steel and some low-alloy steels.

2. Deoxidation The inclusion of deoxidizers helps to prevent oxidation during the welding process, leading to a cleaner and stronger weld. This is particularly important for applications exposed to outdoor elements, as it improves corrosion resistance.

3. Versatility ER70S-6 can be used in many applications, including automotive repair, shipbuilding, structural steel fabrication, and more. Its versatility makes it a go-to choice for welders across various industries.

4. Welding Positions This wire can be used in all welding positions, including flat, horizontal, vertical, and overhead. However, it is particularly effective in flat and horizontal positions due to its smooth arc and manageable spatter.

Applications of ER70S-6 Welding Wire

ER70S-6 welding wire is widely utilized across diverse fields due to its robustness and reliability. Some of the most common applications include

welding wire er70s-6 15kg factory

- Automotive Industry It is often used for repairing and assembling various automotive components due to its high strength and ability to produce clean welds that can withstand stress and strain.

- Construction In architectural and structural construction, ER70S-6 is employed for welding beams, columns, and other structural elements, ensuring strong and durable connections.

.

- Manufacturing From heavy machinery to consumer goods, this welding wire supports the fabrication of numerous products, contributing to their overall quality and longevity.

- Repair and Maintenance The wire is frequently used in repair shops for fixing cracked or damaged metal parts, offering a reliable solution for maintaining machinery and equipment.

Sourcing Quality ER70S-6 Welding Wire

When looking for ER70S-6 welding wire, it is crucial to purchase it from a reputable factory or manufacturer. High-quality welding wire ensures better performance, fewer defects, and a more efficient welding process. Consider the following factors when sourcing your welding wire

1. Certifications Check for industry standards and certifications that authenticate the quality of the wire. Look for manufacturers that adhere to ISO standards or similar regulatory requirements.

2. Reputation Research the manufacturer's reputation in the industry. Customer reviews, testimonials, and case studies can provide insight into the wire’s performance and the company's reliability.

3. Product Range A factory that offers a variety of welding wires and related products may have greater expertise in production, which can reflect in the quality of the ER70S-6 wire.

4. Technical Support Opt for suppliers that offer technical support and guidance on welding applications. This can be invaluable for both novice and experienced welders.

Conclusion

ER70S-6 welding wire is a fundamental component of many welding processes, known for its strength, versatility, and ease of use. Understanding its features and applications can significantly enhance welding outcomes, making it a preferred choice in various industries. When sourcing this welding wire, prioritize quality and reliability to ensure the best possible results in your welding projects. Whether you’re involved in manufacturing, repairs, or construction, ER70S-6 wire will be a valuable addition to your welding arsenal.

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025