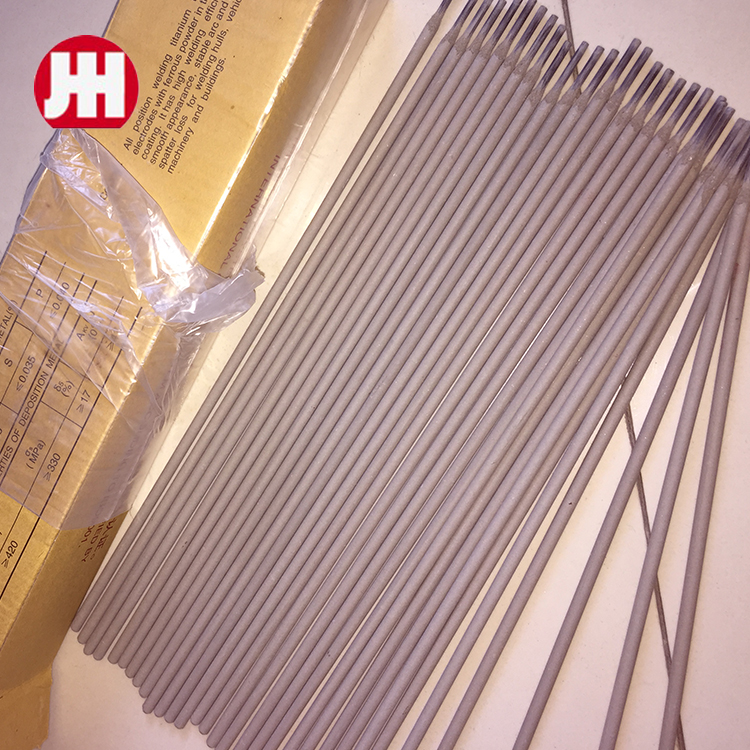

wholesale e6011 welding rod factories

Understanding Wholesale E6011 Welding Rod Factories A Comprehensive Overview

Welding rods are essential components in the welding process, and they come in various types tailored for specific applications. Among the many available, the E6011 welding rod is notable for its versatility and effectiveness. This article explores the significance of wholesale E6011 welding rod factories, focusing on their production processes, market dynamics, and the advantages they offer to welders and manufacturers alike.

What is an E6011 Welding Rod?

The E6011 welding rod is a type of stick electrode used primarily in shielded metal arc welding (SMAW). It is coated with a cellulose-based material that generates a shielding gas upon heating, thus protecting the molten weld pool from atmospheric contamination. The E in E6011 stands for electrode, 60 indicates the minimum tensile strength of 60,000 psi, 1 signifies that it can be used in all positions, and the second 1 denotes the type of coating. This rod is well-known for its ability to maintain a stable arc and its strong penetration capability, making it suitable for welding mild steel.

The Role of Wholesale Factories

Wholesale E6011 welding rod factories play a crucial role in the supply chain of welding materials. These factories specialize in producing bulk quantities of welding rods at competitive prices. By operating on a wholesale level, they cater to a variety of customers, including construction companies, automotive manufacturers, and repair shops. The high production volume allows them to capitalize on economies of scale, reducing costs for both the factory and the end-users.

Production Process

The manufacturing process of E6011 welding rods involves several key steps

1. Raw Material Selection Quality raw materials, including metal powders and fluxing agents, are crucial for producing high-quality welding rods. Factories often source these materials from reputable suppliers to ensure consistency and performance.

2. Mixing and Extrusion The selected materials are mixed to create a homogenous blend. This mixture is then extruded into the desired rod shape, ensuring uniformity in diameter and coating thickness.

3. Drying and Coating The extruded rods are dried to remove moisture, followed by the application of the cellulose coating. This step is vital as the coating affects the performance and characteristics of the welding rod.

4. Packaging Once the welding rods are produced and inspected for quality, they are packaged for distribution. Efficient packaging solutions help maintain the quality of the rods during transportation and storage.

wholesale e6011 welding rod factories

Market Dynamics

The demand for E6011 welding rods is influenced by several factors, including the overall growth of the manufacturing and construction industries. As infrastructure projects expand globally, the need for reliable welding materials continues to rise. Wholesale factories that can ensure a steady supply of high-quality E6011 rods are positioned to capitalize on this growing demand.

Furthermore, the competitive nature of the welding rod market drives factories to innovate. They strive to enhance the properties of their welding rods, such as improving arc stability and reducing spatter, to meet the evolving needs of welders. As a result, many wholesale factories invest in research and development to stay ahead in the market.

Advantages for Customers

Purchasing E6011 welding rods from wholesale factories offers several advantages

- Cost-Effectiveness Bulk purchasing significantly reduces costs per unit, which is beneficial for businesses looking to manage their budgets effectively.

- Consistent Quality Reputable wholesale factories maintain stringent quality control measures, ensuring that every batch of welding rods meets industry standards.

- Variety and Availability Wholesale factories often stock a wide range of welding rods and related materials, allowing customers to find the products that best suit their needs without delays.

- Technical Support Many wholesale suppliers provide technical assistance and guidance on the best practices for using their products, helping welders achieve optimal results.

Conclusion

Wholesale E6011 welding rod factories are vital players in the welding industry. They not only provide essential materials but also contribute to the overall efficiency and effectiveness of welding operations across various sectors. By understanding the dynamics of these factories, customers can make informed decisions, ensuring they select the right welding rods for their projects. As the demand for high-quality welding materials continues to grow, wholesale factories will remain crucial in meeting the needs of welders worldwide.

-

Arc Welding Electrodes AWS E7024 – High Deposition, Smooth FinishNewsJul.30,2025

-

E7016 Welding Rods for Smooth, Low Hydrogen Welding PerformanceNewsJul.29,2025

-

E7016 Welding Rods for High Strength & Low Hydrogen WeldingNewsJul.29,2025

-

High Quality Carbon Rods for Welding – Durable & Precise ResultsNewsJul.29,2025

-

High-Performance Cellulose Electrode E6010 for Steel WeldingNewsJul.28,2025

-

High Quality E71T-11 Welding Wire from China – Flux Cored, Easy to UseNewsJul.28,2025