china co2 mig mag welding wire manufacturer

Leading China CO2 MIG MAG Welding Wire Manufacturers

In the realm of welding, CO2 MIG (Metal Inert Gas) and MAG (Metal Active Gas) welding processes have gained immense popularity due to their efficiency and effectiveness in joining various metals. Central to these processes is the quality of welding wire, as it directly influences the weld's strength, appearance, and overall performance. In China, several manufacturers have established themselves as leaders in producing high-quality CO2 MIG/MAG welding wire.

Leading China CO2 MIG MAG Welding Wire Manufacturers

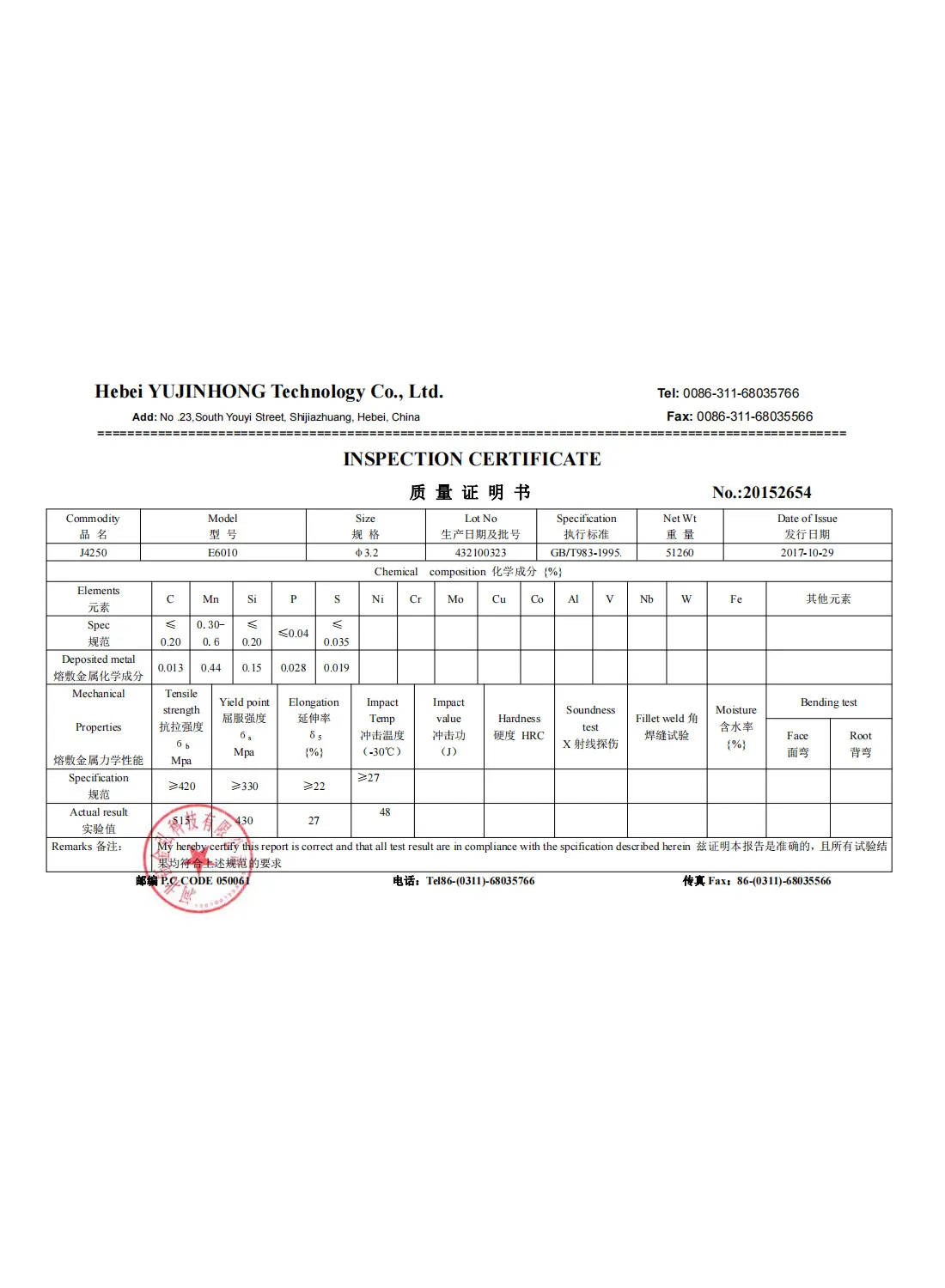

The raw materials used in the manufacturing of welding wires play a crucial role in determining the final product's quality. Renowned manufacturers in China source high-grade materials to ensure optimal performance. These manufacturers often conduct rigorous quality control tests at different production stages to guarantee that their welding wire is consistent in diameter, strength, and chemical composition. This meticulous attention to detail ensures that the welding wires are reliable for critical applications in industries such as construction, automotive, shipbuilding, and manufacturing.

china co2 mig mag welding wire manufacturer

Moreover, Chinese manufacturers are known for their ability to produce welding wires in a wide range of specifications, catering to various customer needs. Whether it’s for standard applications or specialized use in demanding environments, these manufacturers can customize their products to achieve the desired welding characteristics. This flexibility has made them preferred suppliers for businesses both domestically and internationally.

Additionally, as global demand for eco-friendly welding solutions continues to grow, many Chinese manufacturers are adapting their production processes to be more sustainable. They are focusing on developing welding wires that minimize environmental impact while still delivering exceptional performance. This approach not only aligns with global sustainability goals but also enhances the reputation of Chinese manufacturers in the international market.

Furthermore, the competitive pricing offered by Chinese CO2 MIG/MAG welding wire manufacturers is another significant factor contributing to their success. By streamlining production processes and optimizing supply chains, these manufacturers can keep costs down without compromising on quality. This affordability, combined with their advanced technology and high standards, makes them a viable option for businesses looking to source welding materials.

In conclusion, China has solidified its position as a leading manufacturer of CO2 MIG/MAG welding wire, thanks to its commitment to quality, innovation, and customer-specific solutions. As industries continue to evolve and demand sophisticated welding solutions, Chinese manufacturers are well-equipped to meet these challenges while maintaining a focus on sustainability and cost-effectiveness. Their prominence in the global welding market is a testament to their expertise and dedication to excellence.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025