china filler welding rod manufacturers

The Landscape of China’s Filler Welding Rod Manufacturers

In recent years, China has established itself as a global powerhouse in the manufacturing sector, with a particular emphasis on industries that cater to construction, automotive, and heavy machinery. One vital component in the field of fabrication and manufacturing is the welding rod. Filler welding rods play a critical role in the welding process, serving as the material that fuses with the base metals to create strong and durable joints. This article delves into the landscape of China’s filler welding rod manufacturers, highlighting the factors that contribute to their prominence in the global market.

Overview of Filler Welding Rods

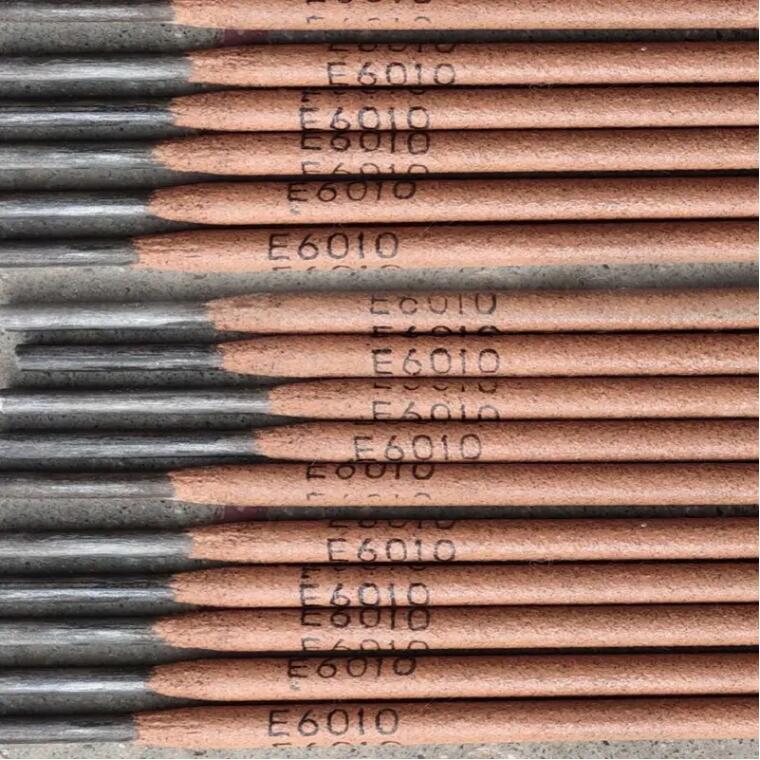

Filler welding rods, often referred to as welding electrodes, are essential for virtually all welding applications, including electric arc and gas welding. These rods are designed to melt during the welding process, adding material to the joint and filling gaps between the base metals. Common materials for welding rods include stainless steel, mild steel, and alloyed materials, each suited for specific welding applications based on their mechanical properties and the type of metals being joined.

The Rise of Chinese Manufacturers

China has witnessed a surge in its welding rod manufacturing capabilities over the past few decades. This growth can be attributed to several key factors

1. Cost Efficiency Chinese manufacturers benefit from lower labor costs compared to their counterparts in Western nations. Additionally, the availability of raw materials at competitive prices further drives manufacturing costs down, allowing for attractive pricing strategies.

2. Technological Advancements Investment in technology has allowed Chinese manufacturers to improve the quality and performance of their welding rods. Automation and modern production techniques have enhanced consistency and efficiency, ensuring that products meet international standards.

3. Government Support The Chinese government has actively supported industrial growth through various initiatives aimed at enhancing domestic production capabilities and promoting export-oriented manufacturing sectors. This includes financial incentives, subsidies, and infrastructure development.

4. Diverse Product Range Chinese manufacturers offer a wide variety of filler welding rods designed to cater to different industries and applications. This diversity not only meets the domestic demand but also positions them to export to international markets, including Europe, the Americas, and Asia-Pacific.

china filler welding rod manufacturers

Quality Assurance and Standards

Quality assurance is critical in the welding industry, given that welding defects can compromise the integrity of structures and components. Chinese manufacturers often adhere to international and national standards, such as ISO 9001 for quality management systems and AWS (American Welding Society) standards for welding products. Many manufacturers also engage in rigorous testing and quality control processes to ensure that their products perform reliably under various conditions.

Challenges Faced by Manufacturers

Despite their growth and global reach, Chinese filler welding rod manufacturers face several challenges. Increased global competition, particularly from countries with emerging manufacturing industries, puts pressure on pricing and innovation. Moreover, fluctuations in raw material prices due to global market trends can impact production costs. There are also ongoing concerns about environmental regulations and sustainability practices, which manufacturers must navigate to comply with international standards.

Future Outlook

The future for China’s filler welding rod manufacturing sector appears promising. As industries worldwide continue to expand and modernize, the demand for high-quality welding materials is poised to increase. Chinese manufacturers, with their robust production capabilities, technological advancements, and strategic pricing, are well-positioned to cater to this growing demand.

Moreover, as global trends lean towards sustainability, manufacturers are likely to invest in developing eco-friendly products and practices. This shift can enhance their competitiveness and align them with international market requirements.

Conclusion

In conclusion, the landscape of filler welding rod manufacturers in China is characterized by competitive pricing, diverse product offerings, and continuous innovation. As the country continues to strengthen its position in the global manufacturing arena, these manufacturers are set to play a pivotal role in meeting the demands of the welding industry both domestically and abroad. Their resilience and adaptability will be crucial as they navigate challenges and seize opportunities in the evolving market landscape.

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025

-

Arc Welding Electrodes AWS E7024 – High Deposition, Smooth FinishNewsJul.30,2025