Top Suppliers of MIG Welder Wire in China for Quality Welding Solutions

Understanding the Sources of MIG Welder Wire in China

In the realm of industrial manufacturing and fabrication, the importance of selecting high-quality welding materials cannot be overstated. Among the options available, Metal Inert Gas (MIG) welding has gained significant popularity due to its versatility and efficiency. As the demand for MIG welding continues to grow, so does the need for reliable MIG welder wire suppliers. In this context, China has emerged as a major player in the global market, offering a diverse range of welding wires and materials.

The Significance of MIG Welding

MIG welding is favored for several reasons, including its speed, ease of use, and ability to weld various metals, including steel, aluminum, and stainless steel. The process utilizes a continuous wire feed as an electrode, creating a molten pool that fuses materials together. The quality of the welding wire directly influences the structural integrity of the weld; therefore, selecting a trustworthy supplier is critical.

China's Position in the MIG Welder Wire Market

China has established itself as one of the largest producers of welding materials in the world. The nation's advanced manufacturing capabilities, coupled with lower production costs, have positioned it as a leading supplier for various welding products, including MIG welder wire. Chinese manufacturers offer a wide range of options tailored to different types of welding applications, ensuring that they can meet the diverse needs of customers worldwide.

Key Factors to Consider When Choosing a Supplier

When selecting a MIG welder wire supplier in China, several factors should be considered to ensure that you procure high-quality products

1. Quality Assurance It is crucial to verify that the supplier adheres to international quality standards, such as ISO 9001. Quality certifications reflect a commitment to manufacturing excellence and can provide assurance that the welding wire will perform as expected.

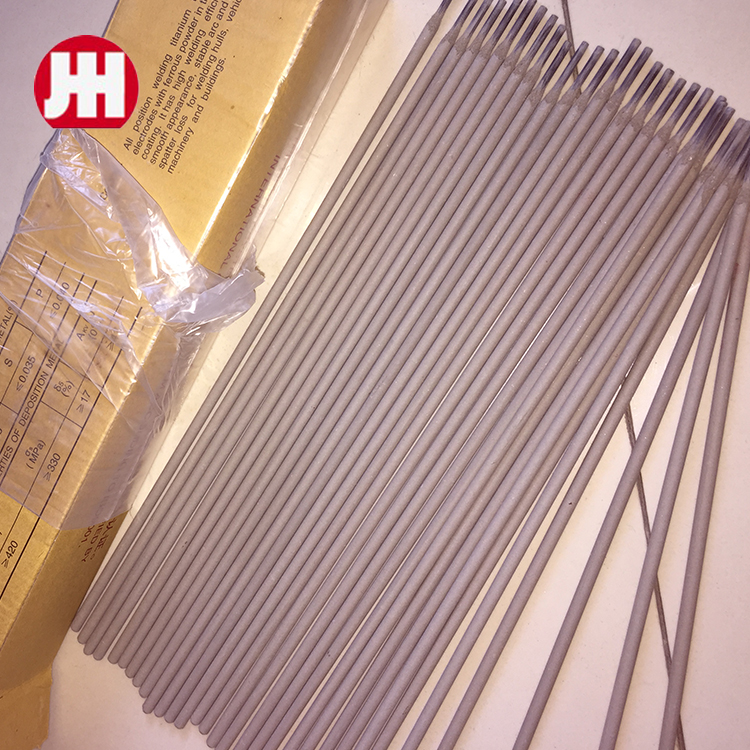

china mig welder wire supplier

2. Material Specifications Different welding projects require specific types of MIG welding wire, such as ER70S-6 for general use or ER308L for stainless steel applications. Understanding the material specifications and ensuring that the supplier can meet these needs is essential for achieving optimal welding results.

3. Production Capacity Assessing the supplier's production capacity can provide insights into their ability to meet high-volume orders. If your project requires a large quantity of MIG wire, it is vital to choose a supplier that can deliver consistently and on time.

4. Technical Support and Documentation A reputable supplier should provide technical data sheets and documentation pertaining to their MIG welding wire products. This information is useful for ensuring compliance with industry standards and for understanding the properties of the materials.

5. Customer Reviews and Feedback Researching customer reviews and testimonials can help gauge the reliability and performance of the supplier. Feedback from other businesses in similar industries can provide insights into the quality of the welding wire and the supplier's service level.

The Future of MIG Welder Wire Supply in China

As global demand for welding materials continues to increase, Chinese suppliers are investing in advanced technologies and innovative manufacturing processes. This commitment to modernization helps them enhance product quality and expand their offerings. Furthermore, the emphasis on environmental sustainability is influencing the production methods in China, with a growing number of suppliers adopting eco-friendly practices.

Conclusion

In conclusion, the landscape of MIG welder wire supply in China is both rich and complex, characterized by a multitude of suppliers offering a variety of products. Understanding the significance of quality and the key factors to consider when selecting a MIG welding wire supplier is crucial for any business involved in welding applications. As China remains a dominant force in the global welding industry, companies that take the time to research and choose the right supplier can benefit greatly from the high-quality materials offered by Chinese manufacturers. This not only ensures successful welding outcomes but also contributes to the overall efficiency and productivity of manufacturing processes.

-

E71T-11 Flux Core Wire: Premium Gasless Welding SolutionNewsAug.28,2025

-

Premium Carbon Rods for Welding | Stable Arc & Precise GougingNewsAug.27,2025

-

Carbon Steel Welding Wire: Superior Strength & PrecisionNewsAug.26,2025

-

AWS E6013 Welding Electrodes: All-Position & Smooth Arc RodsNewsAug.25,2025

-

E312 Electrode: High Strength Welding Rod for Dissimilar MetalsNewsAug.24,2025

-

J506 Welding Rod: High-Strength, Crack-Resistant ElectrodeNewsAug.23,2025