china mig wire 0.8mm co2 factory

The Rise of China’s MIG Wire Industry A Focus on 0.8mm CO2 Welding Wires

The global welding industry has undergone significant transformation over the past few decades, with advancements in technology and an increasing demand for efficient welding solutions. Among these advancements, Metal Inert Gas (MIG) welding has become increasingly popular due to its versatility and efficiency. One of the key components in MIG welding is the welding wire, and China’s production of 0.8mm CO2 welding wires has become a crucial subject in this context.

Understanding MIG Welding

MIG welding, also known as Gas Metal Arc Welding (GMAW), is a process that uses a continuous feed of wire to join two pieces of metal together. This method employs a shielding gas, typically carbon dioxide (CO2) or a mix of gases, to protect the weld pool from contamination. The use of a 0.8mm diameter wire has become common in various applications due to its ability to produce strong, clean welds while maintaining a manageable heat input.

China’s Dominance in MIG Wire Production

China has emerged as a dominant player in the global welding wire market. The country’s extensive manufacturing capabilities, coupled with investments in technology and infrastructure, have positioned it as a leading manufacturer of MIG welding wires, including the widely used 0.8mm CO2 wires. With a combination of lower production costs and high-quality products, Chinese manufacturers are increasingly meeting the needs of both domestic and international markets.

Quality of 0.8mm CO2 MIG Wires

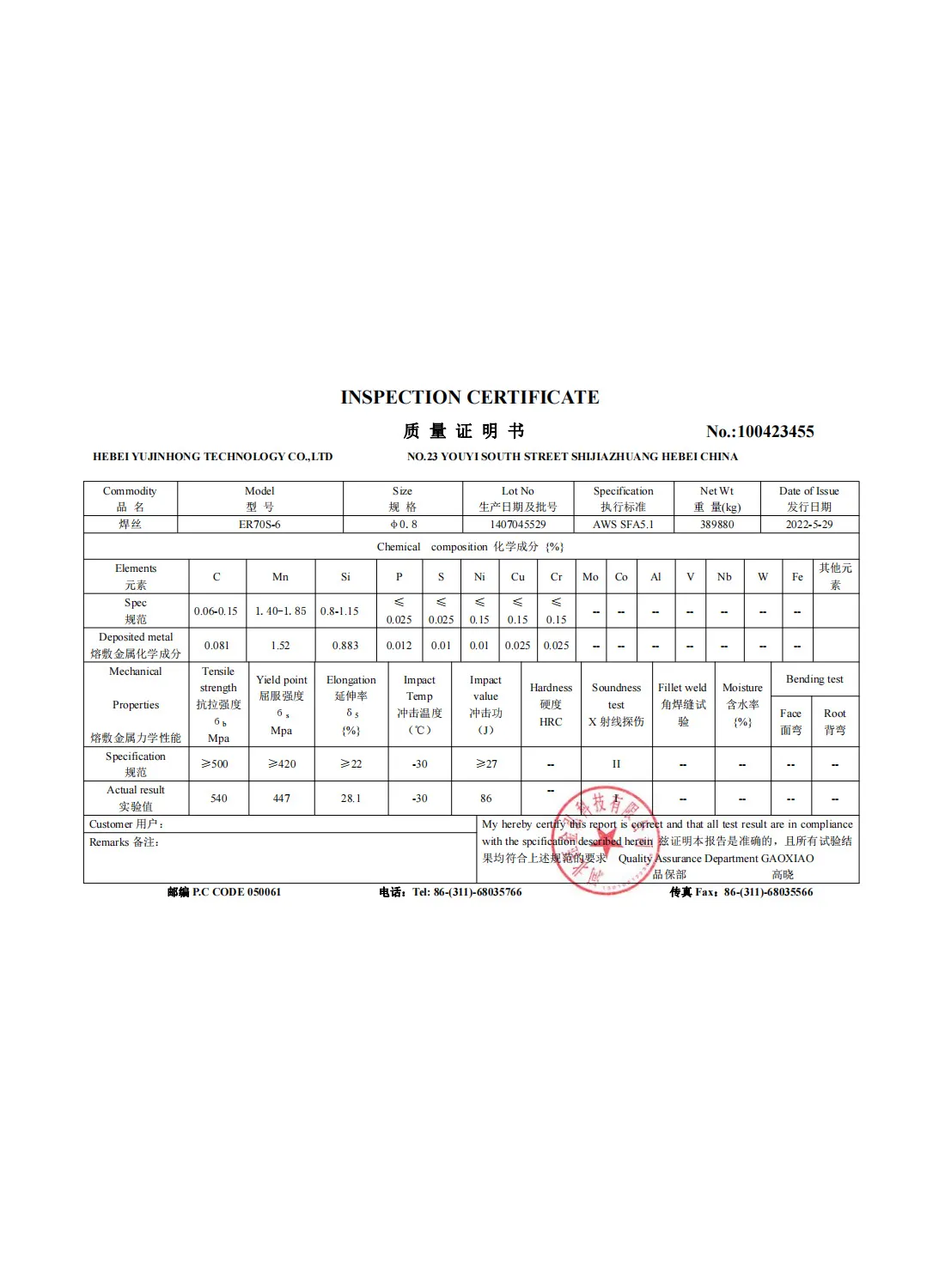

The quality of welding wires is paramount to the success of any welding operation. Chinese factories are focusing on enhancing quality control measures to produce 0.8mm CO2 MIG wires that meet international standards. These wires undergo rigorous testing for tensile strength, ductility, and corrosion resistance, ensuring they can withstand varied welding environments. Using high-quality raw materials, along with advanced manufacturing processes, allows Chinese manufacturers to deliver products that consistently perform well.

china mig wire 0.8mm co2 factory

Applications of 0.8mm CO2 MIG Wires

0.8mm CO2 MIG wires are versatile and can be used in a variety of applications, from automotive manufacturing to construction and fabrication. Their ability to produce clean and aesthetically pleasing welds makes them particularly popular in industries where appearance is important. Additionally, the efficiency of the welding process when using 0.8mm wire allows for faster production cycles, leading to increased output and reduced labor costs.

Environmental Considerations

As the welding industry expands, so do concerns about environmental impact. The production of CO2 MIG wires has environmental implications, particularly in terms of gas emissions. However, many Chinese manufacturers are investing in green technologies and practices to minimize their environmental footprint. From using recyclable materials to optimizing production processes for energy efficiency, these efforts are being recognized globally.

The Future of MIG Wire Production in China

The future of China’s 0.8mm CO2 MIG wire production appears promising as the country continues to adapt to changing technology and market demands. Researchers and manufacturers are exploring new alloy compositions that enhance performance while reducing costs. Moreover, with the rise of automation in manufacturing, the efficiency of MIG wire production is predicted to improve significantly, allowing for greater output and profitability.

Conclusion

The significance of 0.8mm CO2 MIG wires in the welding industry cannot be overstated, and China’s role in their production is increasingly central to the global supply chain. With a focus on quality, efficiency, and environmental responsibility, Chinese manufacturers are not only competing on a global scale but are setting new standards in the welding industry. As these advancements continue, it is likely that China's influence in the MIG wire market will only grow, shaping the future of welding technology worldwide.

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025