China Supplier of Welding Electrodes for High-Quality Performance and Durability

Exploring the Landscape of China’s Electrode Welding Supplies

Welding, an essential manufacturing process, plays a vital role in various industries around the globe. One of the critical components of welding is the electrode, particularly for arc welding processes. As the demand for high-quality welding products continues to rise, China has emerged as a significant player in the global electrode market. This article delves into the reasons behind China’s dominance as a supplier of welding electrodes and what buyers should consider when sourcing these materials.

The Manufacturing Hub of Electrode Welders

China is often referred to as the world's factory, and the production of welding electrodes is no exception. The country boasts a robust manufacturing infrastructure, skilled labor force, and competitive pricing. By leveraging advanced technology and efficient production processes, Chinese manufacturers can produce a wide range of welding electrodes that meet various international standards. From basic consumables to specialized electrodes for unique applications, the breadth of offerings is impressive.

Quality and Standards

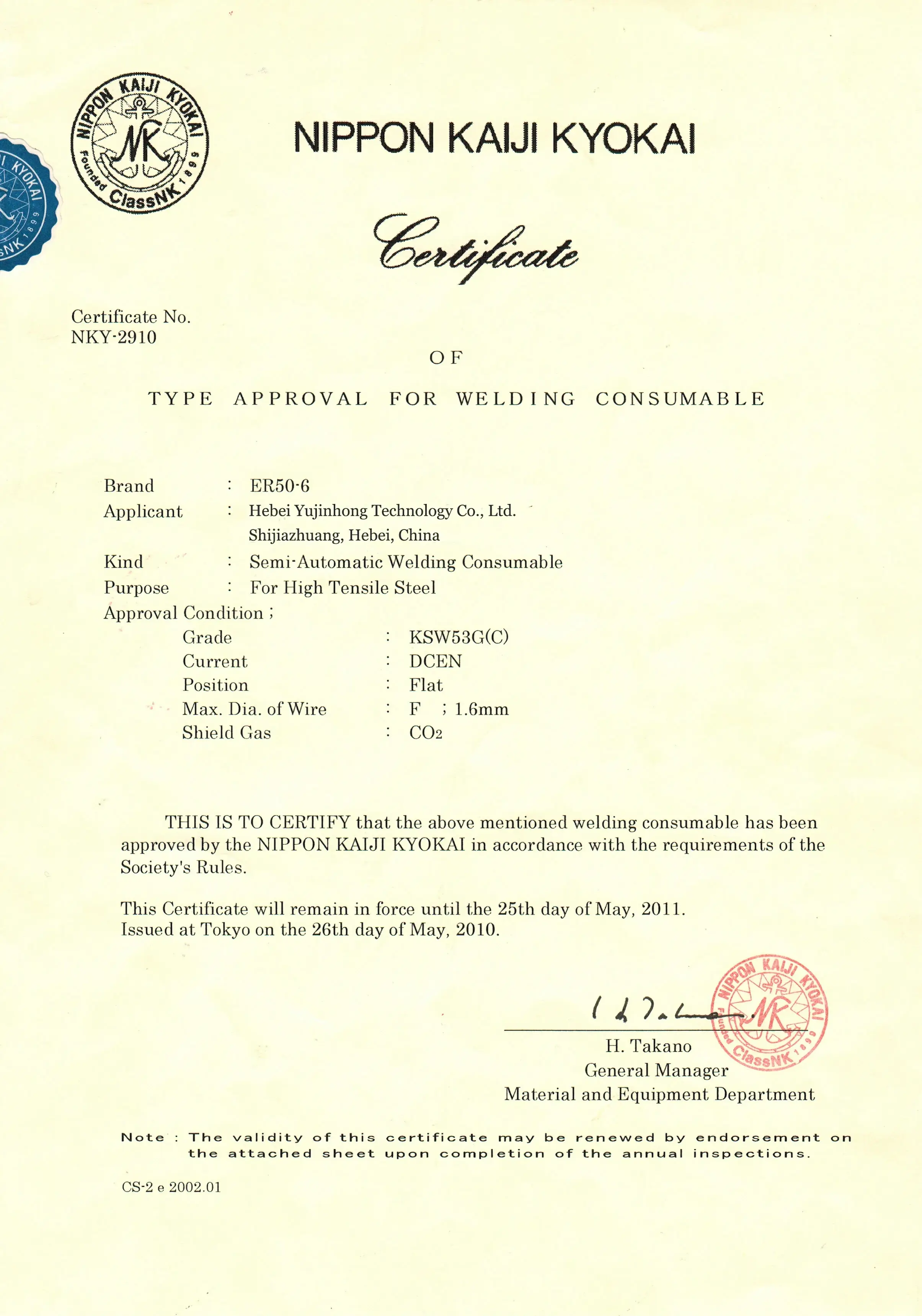

Quality assurance is a paramount concern for buyers. Chinese suppliers are increasingly adopting international quality standards such as ISO 9001 to ensure that their products meet global benchmarks. Many producers also engage in rigorous testing protocols, including tensile strength tests and chemical composition analyses, to guarantee the reliability and performance of their electrodes. Buyers should look for certifications and comply with local regulations when selecting a supplier to ensure quality and safety.

Diversity of Products

One of the significant advantages of sourcing welding electrodes from China is the variety of products available. This diversity caters to multiple welding techniques, including MIG, TIG, and stick welding. Suppliers often customize their products according to specific requirements, allowing companies to find exactly what they need for their projects. Whether it's low hydrogen electrodes for critical applications or alloy electrodes for heavy-duty welds, Chinese manufacturers have a solution.

china soldadora electrodos supplier

Cost-Effectiveness

Cost is always a critical factor in manufacturing and procurement. Chinese suppliers typically provide competitive pricing due to lower labor costs and economies of scale. For businesses seeking to reduce manufacturing costs without compromising quality, sourcing welding electrodes from China can be a strategic advantage. However, it's essential to balance cost with quality, ensuring that savings do not come at the expense of performance and reliability.

Logistics and Supply Chain

When considering a Chinese supplier for welding electrodes, logistics and supply chain management are pivotal. Many manufacturers have established extensive distribution networks. By leveraging these networks, companies can ensure timely delivery of their orders, preventing production delays. Additionally, understanding shipping terms and regulations is vital, as these factors can influence overall costs and timelines.

Building Relationships with Suppliers

Establishing strong relationships with suppliers is crucial for long-term success. Open communication channels can lead to improved product customization, better pricing negotiations, and enhanced service quality. Many Chinese suppliers are keen on building partnerships with international buyers, which can facilitate smoother transactions and foster trust.

Conclusion

China’s role as a leading supplier of welding electrodes is underscored by its manufacturing capabilities, product diversity, competitive pricing, and commitment to quality. For companies in need of dependable welding solutions, exploring Chinese suppliers can open up a world of opportunities. However, it’s essential to conduct thorough research, evaluate suppliers carefully, and cultivate strong working relationships to harness the full potential of China's welding electrode market. By doing so, businesses can ensure they have the right products to meet their welding needs, thereby enhancing their overall productivity and success in the industry.

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025